3590628

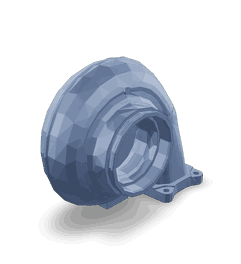

Turbine Housing

Cummins®

DISCONTINUED

This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbine Housing 3590628 by Cummins is a critical component in the turbocharger system, especially for heavy-duty trucks. This part facilitates efficient turbocharger operation by managing exhaust gas flow, enhancing engine performance and efficiency.

Basic Concepts of Turbine Housing

Turbine housings are essential in turbocharger systems, encapsulating the turbine wheel spun by exhaust gases. This action drives the compressor wheel, compressing incoming air before it enters the engine’s combustion chambers. The housing’s design and material significantly impact the turbocharger’s efficiency and engine performance 1.

Purpose of the 3590628 Turbine Housing

The 3590628 Turbine Housing is engineered to optimize exhaust gas flow over the turbine wheel. Efficient gas direction enhances the turbine’s ability to spin the compressor wheel, increasing air volume and pressure entering the engine. This results in improved combustion efficiency and increased power output, vital for heavy-duty truck operations 2.

Key Features

This Cummins part features high-quality materials resistant to high temperatures and pressures. Its design ensures optimal airflow and minimal turbulence, enhancing turbocharger efficiency. It also includes robust mounting points and seals for a secure fit and leak prevention.

Benefits

Incorporating the 3590628 Turbine Housing into a truck’s turbocharger system offers improved engine performance through efficient turbocharger operation. This leads to increased fuel efficiency and long-term reliability due to its durable construction 3.

Installation Process

Installing the 3590628 Turbine Housing requires careful attention to ensure optimal performance. The process involves securing the housing to the engine’s exhaust manifold, ensuring tight connections and intact seals. Using the correct tools and following manufacturer guidelines is crucial to avoid damaging the component or compromising its efficiency. Alignment checks should confirm proper installation.

Common Issues and Troubleshooting

Common issues with the 3590628 Turbine Housing include leaks, cracks, or performance decline, often due to improper installation, wear and tear, or extreme conditions. Troubleshooting involves inspecting the housing for physical damage, checking seals and connections for integrity, and ensuring the turbocharger system operates within specified parameters.

Maintenance Tips

Regular maintenance is recommended to prolong the lifespan of the 3590628 Turbine Housing. This includes inspecting for wear or damage, cleaning to remove buildup that could impede airflow, and following recommended service intervals for the turbocharger system. These practices help maintain turbocharger efficiency and reliability.

Compatibility and Application

The 3590628 Turbine Housing is designed for specific heavy-duty truck models, ensuring compatibility with the engine and turbocharger system. Understanding its specific applications aids in selecting the appropriate component for a given truck.

Cummins Overview

Cummins Inc. is renowned for its high-quality engine and turbocharger components, known for reliability and efficiency in heavy-duty applications. The company’s turbocharger components, including the 3590628 Turbine Housing, are designed with precision and durability, reflecting Cummins’ commitment to quality and performance.

Conclusion

The 3590628 Turbine Housing by Cummins is a vital component in turbocharger systems, enhancing engine performance and efficiency in heavy-duty trucks. Its design, material, and precise engineering contribute to optimal turbocharger operation, offering benefits such as increased fuel efficiency and long-term reliability. Proper installation, maintenance, and understanding of its compatibility and application are essential for maximizing its performance and lifespan.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.