This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

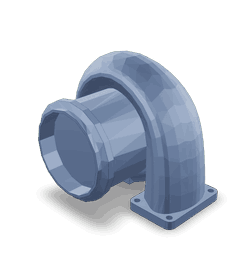

The Cummins 3591172 Turbine Housing is a component designed to enhance the performance of turbocharger systems in commercial trucks. Its role is to house the turbine wheel, which is driven by exhaust gases to spin the compressor wheel, thereby increasing the air intake and boosting engine power. This housing is significant for maintaining the efficiency and reliability of the turbocharger, which is vital for the overall performance of the engine 1.

Basic Concepts of Turbine Housing

Turbine housings are integral to the functionality of turbochargers. They encase the turbine wheel, which is spun by the flow of exhaust gases exiting the engine. This spinning action drives the compressor wheel via a shared shaft, which compresses incoming air before it enters the engine’s combustion chambers. The efficiency of this process is influenced by the design and material of the turbine housing, as well as its relationship with the compressor housing. Together, these components play a role in enhancing engine efficiency by optimizing the air-fuel mixture and improving combustion 2.

Purpose of the 3591172 Turbine Housing

The 3591172 Turbine Housing is specifically engineered to facilitate the efficient operation of a truck’s turbocharger. It contributes to the turbocharger’s function by providing a robust and precise enclosure for the turbine wheel. This housing ensures that exhaust gases are directed effectively to spin the turbine, which in turn drives the compressor wheel. The result is an increase in the volume and pressure of air entering the engine, leading to enhanced engine performance and power output 3.

Key Features

The 3591172 Turbine Housing is characterized by several design and manufacturing features that enhance its performance and durability. It is constructed from high-quality materials that can withstand the high temperatures and pressures of exhaust gases. The housing is precision-engineered to ensure optimal airflow and efficiency. Additionally, it may feature unique attributes such as advanced coatings or specific geometric designs that further improve its performance under demanding conditions.

Benefits

The advantages provided by the 3591172 Turbine Housing include improved engine efficiency, increased power output, enhanced fuel economy, and reduced emissions. By optimizing the turbocharger’s operation, this housing contributes to a more efficient combustion process, which can lead to better overall engine performance. Additionally, the enhanced airflow and pressure can result in increased power, improved fuel efficiency, and lower emissions, making it a valuable component for commercial truck engines.

Installation Considerations

Proper installation of the 3591172 Turbine Housing is important for ensuring its effectiveness and longevity. It is compatible with various engine models, and the installation process requires specific tools and adherence to manufacturer guidelines. Step-by-step procedures should be followed to ensure that the housing is securely fitted and properly aligned with the turbocharger and exhaust system. Attention to detail during installation can prevent issues such as leaks or reduced performance.

Troubleshooting Common Issues

Common problems associated with turbine housings include leaks, cracks, and performance issues. These can often be identified through visual inspection or performance diagnostics. Suggested methods for addressing these issues may involve repairing cracks, sealing leaks, or replacing the housing if it is severely damaged. Regular monitoring and maintenance can help in early detection and resolution of these problems.

Maintenance Tips

To ensure the longevity and optimal performance of the 3591172 Turbine Housing, routine maintenance practices are recommended. This includes regular inspection intervals to check for signs of wear, damage, or leaks. Cleaning procedures should be performed to remove any buildup that could affect performance. Monitoring for wear and tear and addressing issues promptly can help maintain the efficiency and reliability of the turbocharger system.

Cummins Overview

Cummins Inc. is a well-established company with a long history in the commercial truck industry. Known for its wide range of products and strong reputation for quality and reliability, Cummins provides components that are designed to meet the demanding requirements of commercial applications. The 3591172 Turbine Housing is a testament to Cummins’ commitment to delivering high-quality, durable, and efficient parts for the trucking industry.

Turbine Housing Part 3591172 Compatibility with Cummins Engines

The Turbine Housing part number 3591172, manufactured by Cummins, is a critical component that fits seamlessly into various Cummins engine models. This part is integral to the operation of the turbocharger system, ensuring efficient airflow and optimal engine performance.

K38 Engines

The K38 engine series benefits from the precise engineering of the Turbine Housing part 3591172. This part is designed to fit snugly within the K38’s turbocharger assembly, facilitating the smooth movement of exhaust gases and enhancing the overall efficiency of the engine.

QSK45 CM500 and QSK60 CM500 Engines

Both the QSK45 CM500 and QSK60 CM500 engines are equipped with the Turbine Housing part 3591172. This part is specifically engineered to integrate with the turbochargers of these models, providing a robust and reliable solution for maintaining high performance levels. The design ensures that the turbine housing can withstand the high pressures and temperatures associated with these powerful engines.

QSK60G Engines

The QSK60G engine series also utilizes the Turbine Housing part 3591172. This part is crafted to fit perfectly within the turbocharger system of the QSK60G, ensuring that the engine operates at peak efficiency. The design of this turbine housing is optimized to handle the demanding conditions of the QSK60G engine, contributing to its durability and longevity.

Role of Part 3591172 Turbine Housing in Engine Systems

The integration of part 3591172 Turbine Housing within engine systems is fundamental for optimizing performance and efficiency. This component is engineered to work seamlessly with aftermarket turbochargers, enhancing the overall functionality of the turbocharger kit.

When installed, the Turbine Housing directs the flow of exhaust gases, which spin the turbine wheel inside the turbocharger. This action compresses the intake air, leading to increased engine power and efficiency.

In systems equipped with aftercooler plumbing, the Turbine Housing plays a part in maintaining the temperature of the compressed air. By ensuring a steady flow of exhaust gases, it aids in the effective cooling of the air before it enters the engine, thus preventing overheating and potential damage.

The performance of the engine is significantly influenced by the efficiency of the Turbine Housing. Its design and material contribute to the durability and reliability of the turbocharger, making it a key component in high-performance engine setups.

Conclusion

In summary, the 3591172 Turbine Housing is a versatile and essential component for the Cummins K38, QSK45 CM500, QSK60 CM500, and QSK60G engines, providing the necessary structural integrity and performance enhancements required for these high-powered engines. Its role in optimizing turbocharger performance and engine efficiency makes it a critical part of the engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.