This is an oversize product. Additional shipping fees may apply.

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

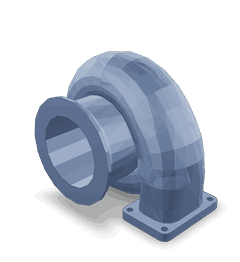

The Cummins 3597922 Turbine Housing is a component designed for use in heavy-duty truck engines. It serves a significant role in the turbocharger system, contributing to the overall performance and efficiency of the engine. Understanding its function and importance can provide valuable insights into the operation of heavy-duty trucks.

Basic Concepts of Turbine Housing

A turbine housing is a part of the turbocharger system that encases the turbine wheel. Its primary function is to direct exhaust gases from the engine to spin the turbine wheel, which in turn drives the compressor wheel to increase the airflow into the engine. This process enhances engine performance by allowing more air to be compressed into the combustion chamber, resulting in more efficient fuel combustion and increased power output 1.

Purpose of the 3597922 Turbine Housing

This Cummins part is specifically engineered to fit within Cummins engine systems. It plays a role in the turbocharger system by housing the turbine wheel and directing exhaust gases to spin it. This action drives the compressor wheel, which increases the airflow into the engine. The result is improved engine efficiency and performance, making it a vital component in the operation of heavy-duty trucks.

Key Features

The 3597922 is constructed from durable materials to withstand the high temperatures and pressures of exhaust gases. Its design includes precise engineering to ensure optimal airflow and efficiency. Unique characteristics such as its robust construction and efficient design contribute to its performance and longevity in heavy-duty applications 2.

Benefits

The use of this part offers several benefits. It contributes to improved engine performance by enhancing the turbocharger’s efficiency. This results in increased fuel efficiency and overall engine power. Additionally, its durable construction ensures it can withstand the demanding conditions of heavy-duty truck operation, providing reliable performance over time 3.

Installation Process

Installing the 3597922 requires careful attention to ensure proper fitting and function. The process involves securing the housing to the engine and turbocharger, ensuring all connections are tight and secure. Using the appropriate tools and following best practices can help achieve a successful installation, contributing to the overall performance of the engine.

Common Issues and Troubleshooting

Common issues with this part may include leaks, cracks, or a decline in performance. These issues can often be identified through regular inspections and maintenance. Troubleshooting may involve checking for proper installation, inspecting for damage, and ensuring all connections are secure. Addressing these issues promptly can help maintain the efficiency and performance of the turbocharger system.

Maintenance Tips

Regular maintenance is key to prolonging the lifespan of the 3597922. This includes periodic inspections for signs of wear or damage, cleaning to remove any buildup that may affect performance, and following manufacturer guidelines for replacement intervals. Proper maintenance can help ensure the housing continues to function efficiently, contributing to the overall performance of the engine.

Performance Enhancements

The 3597922 can contribute to performance enhancements such as increased boost pressure, improved throttle response, and overall engine power. These enhancements are achieved through the efficient operation of the turbocharger system, allowing for more air to be compressed into the engine, resulting in more efficient fuel combustion and increased power output 4.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, particularly known for its diesel engines and components. With a history of innovation and quality, Cummins has built a reputation for producing reliable and high-performance engine parts. The 3597922 is part of their extensive product range, designed to meet the demanding requirements of heavy-duty truck engines.

Application in Cummins Engines

The Turbine Housing is specifically designed to fit within the turbocharger assembly of Cummins engines. It is engineered to withstand high temperatures and pressures, ensuring durability and longevity in demanding environments.

QSK60 Engine Group

The QSK60 engine series, which includes the QSK60 CM500, utilizes the Turbine Housing as a key component in its turbocharger system. This engine is known for its robust performance and reliability, making the Turbine Housing a vital part of its operation.

CM500 Engine Group

Similarly, the CM500 engine series incorporates the Turbine Housing in its turbocharger setup. This engine is designed for heavy-duty applications, and the Turbine Housing plays a crucial role in maintaining the efficiency and power output of the engine.

Importance of the Turbine Housing

The Turbine Housing is essential for the proper functioning of the turbocharger system. It houses the turbine wheel and directs exhaust gases to it, which in turn drives the compressor to supply pressurized air to the engine cylinders. This process enhances engine performance, efficiency, and power output.

Compatibility and Installation

The Turbine Housing is engineered to fit seamlessly within the turbocharger assembly of the specified Cummins engines. Proper installation is critical to ensure optimal performance and longevity of the turbocharger system. Technicians and engineers should follow the manufacturer’s guidelines for installation and maintenance to avoid any potential issues.

Understanding the Integration of Part 3597922 Turbine Housing in Engine Systems

The 3597922 is a key component in the efficient operation of various engine systems, particularly when integrated with aftermarket turbochargers and turbocharger kits. Its role is to house the turbine wheel, which is spun by the exhaust gases exiting the engine. This spinning action drives the compressor wheel via a shared shaft, thus compressing the intake air before it enters the engine’s combustion chambers.

When paired with an aftermarket turbocharger, the Turbine Housing (Part 3597922) ensures that the increased volume of exhaust gases is effectively managed. The design of the housing affects the turbocharger’s performance characteristics, such as spool-up time and maximum boost pressure. A well-matched turbine housing can significantly enhance the responsiveness and power output of the aftermarket turbocharger.

In conjunction with a Turbine Housing Heat Exchanger 80 Kit, Part 3597922 plays a vital role in thermal management. The heat exchanger integrated into the housing helps in cooling the turbine side, which can lead to more efficient turbocharger operation and potentially lower EGTs (Exhaust Gas Temperatures). This is particularly beneficial in high-performance applications where managing heat is essential for maintaining turbocharger longevity and engine reliability.

When included in a turbocharger kit, the Turbine Housing (Part 3597922) is often selected based on the specific requirements of the engine modification. Whether the goal is to achieve higher boost levels, improve low-end torque, or enhance overall engine efficiency, the turbine housing’s design—including its size and shape—directly influences these outcomes.

In summary, the integration of Part 3597922 Turbine Housing with these components is designed to optimize the flow of exhaust gases, enhance turbocharger performance, and contribute to the overall efficiency and power output of the engine system.

Conclusion

The 3597922 Turbine Housing is a critical component in the turbocharger system of Cummins engines, designed to enhance engine performance, efficiency, and power output. Its robust construction, precise engineering, and compatibility with various engine systems make it a vital part for heavy-duty truck applications. Proper installation, maintenance, and understanding of its integration with other components are essential for maximizing its benefits and ensuring the longevity and reliability of the engine system.

-

Van Gelder, Kirk T. Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning, 2018.

↩ -

Carroll, Douglas R. Energy Efficiency of Vehicles. SAE International, 2020.

↩ -

Sheng, Gang. Vehicle Noise, Vibration and Sound Quality. SAE International, 2012.

↩ -

Reif, Konrad. Diesel Engine Management Systems and Components. Springer, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.