This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

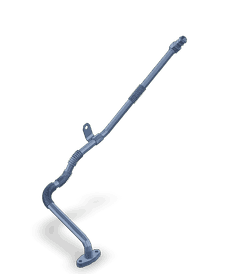

The Turbocharger Oil Drain Connection, part number 2896468, is a critical component for heavy-duty truck engines. It facilitates the drainage of oil from the turbocharger, ensuring efficient and reliable operation. This Cummins part is essential for maintaining engine performance and longevity by enabling regular oil changes and preventing contaminant buildup within the turbocharger system 2.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger oil drain connections are engineered to allow periodic drainage of oil used for lubricating the turbocharger. This process removes impurities and maintains the oil’s lubricating properties. The connection interfaces with the turbocharger housing and is designed to withstand engine compartment pressures and temperatures 3.

Role and Function in Truck Operation

This part plays a significant role in truck engine operation by enabling efficient oil drainage from the turbocharger. Clean oil is necessary for reducing friction and wear on moving parts. The connection works with the turbocharger and the engine’s lubrication system to ensure proper oil supply for lubrication and cooling 4.

Key Features

The 2896468 is characterized by several key features that enhance functionality and durability. It is constructed from high-quality, corrosion-resistant materials. The design includes precise threading for a secure fit with the turbocharger housing, minimizing leak risks. It may also feature a drain plug or valve for controlled oil release during maintenance 1.

Benefits

Using this part offers several benefits. It improves engine performance by ensuring proper turbocharger lubrication, leading to increased efficiency and power output. It enhances reliability by facilitating regular oil changes, preventing turbocharger failure due to contaminated oil. It also simplifies maintenance by providing a straightforward method for draining oil, reducing downtime during service intervals 2.

Installation Process

Installing the 2896468 requires careful attention to detail for a proper fit and seal. The process involves removing the old connection, cleaning the turbocharger housing mating surface, and screwing the new connection into place. It must be tightened to the manufacturer’s specified torque settings to prevent over-tightening or under-tightening 3.

Maintenance and Troubleshooting

Regular maintenance of the 2896468 is important for ensuring continued functionality. This includes periodic inspection for wear or damage and ensuring a secure fastening. Common issues may include oil leaks, often due to improper installation or a damaged connection. Troubleshooting typically involves checking the connection for proper seating and ensuring all components are in good condition 4.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the automotive industry. The company’s product range includes diesel and natural gas engines, as well as related technologies that enhance engine performance and efficiency. Cummins is known for its commitment to customer satisfaction and its focus on developing solutions that meet the evolving needs of the transportation and power generation sectors 1.

Integration with Turbocharger Plumbing

In turbocharger plumbing, the Turbocharger Oil Drain Connection interfaces with the oil supply and return lines. It allows for periodic oil discharge, maintaining lubricant cleanliness and viscosity. The connection is typically located at the lowest part of the turbocharger housing to ensure effective drainage of settled debris and contaminants 2.

Function within the Turbocharger System

The Turbocharger Oil Drain Connection works with the oil feed line, return line, and turbocharger bearing housing. Oil is fed into the turbocharger to lubricate rotating components and bearings. Over time, this oil can become contaminated. The connection provides a controlled method for removing used oil, which is then replaced with fresh lubricant. This process is essential for prolonging turbocharger life and ensuring optimal performance. Regular drainage prevents harmful deposit buildup, reducing friction, wear, and potential turbocharger component failure 3.

Maintenance and Operational Benefits

Incorporating the Turbocharger Oil Drain Connection into the engine system offers several maintenance and operational benefits. It simplifies the oil change process, allowing for more frequent and thorough lubrication system maintenance. This contributes to the overall reliability and efficiency of the turbocharger and the engine. It also allows for easy oil analysis, providing insights into turbocharger condition and identifying potential issues before they become significant problems. This proactive maintenance approach can save time and resources in the long run, making the Turbocharger Oil Drain Connection a valuable component in any turbocharged engine system 4.

Conclusion

The 2896468 Turbocharger Oil Drain Connection is a vital component in maintaining the performance and reliability of heavy-duty truck engines. By facilitating regular oil drainage and analysis, it ensures the turbocharger remains efficiently lubricated and free from contaminants. This part simplifies maintenance, enhances engine performance, and contributes to the longevity of the turbocharger and engine system.

-

Vehicle Dynamics: Theory and Application, Reza N. Jazar, Springer, 2017.

↩ ↩ -

Department of Energy Fundamentals Handbook, Department of Energy, 2015.

↩ ↩ ↩ -

The Complete Vehicle, Michael Trzesniowski, Springer Nature, 2023.

↩ ↩ ↩ -

The Repair of Vehicle Bodies Fifth Edition, Alan Robinson and Andrew Livesey, Elsevier, 2006.

↩ ↩ ↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.