This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Turbocharger Compressor Impeller is a vital component within the turbocharger system, designed to enhance engine performance by increasing the efficiency of air intake and compression. This part is integral to the turbocharger’s ability to boost engine power and efficiency, making it a key element in the operation of modern engines, particularly in heavy-duty trucks 1.

Basic Concepts of Turbocharger Compressor Impeller

Turbochargers operate on the principle of forced induction, where exhaust gases drive a turbine connected to a compressor. The compressor impeller, a critical part of this system, is responsible for compressing the intake air before it enters the engine. This compression increases the air density, allowing more oxygen to enter the combustion chamber and enabling the engine to burn more fuel efficiently 2.

Role of the 3002731 Turbocharger Compressor Impeller in Truck Operation

The 3002731 Turbocharger Compressor Impeller plays a significant role in the operation of a truck’s engine by facilitating the air intake and compression processes. As the impeller spins at high speeds, it draws in air and compresses it, which is then delivered to the engine’s cylinders. This increased air pressure enhances combustion efficiency, leading to improved engine performance and power output 3.

Key Features of the 3002731 Turbocharger Compressor Impeller

The 3002731 Turbocharger Compressor Impeller is characterized by several key features that contribute to its effectiveness and durability. These include its material composition, typically a robust alloy designed to withstand high temperatures and pressures, and its precision-engineered blade design. The manufacturing process ensures high precision, which is crucial for the impeller’s performance and longevity.

Benefits of Using the 3002731 Turbocharger Compressor Impeller

Utilizing the 3002731 Turbocharger Compressor Impeller offers several advantages. It contributes to improved engine efficiency by ensuring optimal air compression, which leads to more complete combustion. This results in increased power output and enhanced fuel economy, making it a valuable component for heavy-duty truck engines where performance and efficiency are paramount.

Troubleshooting and Maintenance Suggestions

To maintain optimal performance and longevity of the 3002731 Turbocharger Compressor Impeller, regular maintenance and troubleshooting are recommended. Common issues may include impeller fouling or damage, which can affect compressor efficiency. Diagnostic procedures should include visual inspections for damage and performance tests to ensure the impeller is operating within specified parameters. Regular cleaning and, if necessary, replacement of the impeller can help maintain engine performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to innovation, quality, and customer satisfaction. The company’s extensive product range and focus on technological advancement make it a preferred choice for heavy-duty truck engines and components.

Turbocharger Compressor Impeller (Part 3002731) Compatibility with Cummins Engines

The turbocharger compressor impeller, part number 3002731, manufactured by Cummins, is a critical component designed to enhance the efficiency and performance of various Cummins engine models. This part is integral to the turbocharger system, ensuring optimal air intake and pressure for combustion.

NH/NT 855 Engines

The NH/NT 855 engines, known for their robust performance and reliability, are well-suited for heavy-duty applications. The turbocharger compressor impeller part 3002731 is specifically engineered to fit these engines, providing the necessary boost to maintain high power output and efficiency. This compatibility ensures that the NH/NT 855 engines can handle demanding tasks with ease.

V28 Engines

Similarly, the V28 engines benefit from the use of the turbocharger compressor impeller part 3002731. This part is designed to integrate seamlessly with the V28 engine’s turbocharger system, enhancing its performance characteristics. The V28 engines, often used in various industrial and commercial applications, rely on this component to deliver consistent power and efficiency.

Grouping of Engines

The turbocharger compressor impeller part 3002731 is compatible with both the NH/NT 855 and V28 engines, making it a versatile choice for Cummins engine users. This compatibility allows for easier maintenance and repair, as the same part can be used across different engine models, reducing inventory needs and simplifying the supply chain.

Role of Part 3002731 Turbocharger Compressor Impeller in Engine Systems

The Part 3002731 Turbocharger Compressor Impeller is an integral component within various engine systems, enhancing performance and efficiency. Its role can be understood by examining its interaction with several key components:

Interaction with the Cylinder Head

The impeller’s primary function is to compress the intake air before it enters the cylinder head. This compressed air mixes with the fuel, creating a denser air-fuel mixture. The denser mixture allows for more efficient combustion, which translates to increased power output and better engine performance.

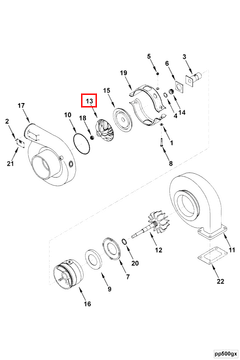

Integration with Turbocharger Systems

In systems such as the Standard-50 Turbocharger and Standard-50 w/Brake Turbocharger, the impeller works in tandem with the turbine to drive the compressor wheel. As exhaust gases spin the turbine, the connected impeller compresses the intake air. This synergy ensures that the engine receives a consistent supply of pressurized air, optimizing combustion efficiency across a range of operating conditions.

Performance Enhancement in Exhaust Brake Systems

For the Exhaust Brake NTC350 and Exhaust Brake NTC400 kits, the impeller’s efficient air compression is vital. These systems rely on precise air-fuel ratios to achieve effective engine braking. The impeller ensures that the turbocharger can maintain the necessary air pressure, even under the demanding conditions of engine braking, thereby enhancing the system’s overall performance.

Role in Turbocharger Repair Kits

In Turbocharger Repair Kits, the impeller is often a replacement part to restore the turbocharger’s functionality. Worn or damaged impellers can lead to reduced compressor efficiency, resulting in lower engine performance. Replacing the impeller with part 3002731 ensures that the turbocharger operates at peak efficiency, maintaining the engine’s power and fuel economy.

Contribution to Wet Manifold Performance Parts

When integrated with Performance Parts Wet Manifold systems, the impeller’s role becomes even more pronounced. These systems demand high levels of air compression to achieve their performance goals. The impeller’s ability to deliver consistent and reliable compression is essential for maximizing the potential of these high-performance engine setups.

Functionality in VT-50 Turbocharger

In the VT-50 Turbocharger, the impeller is a key component in the variable turbine geometry system. It works in conjunction with the adjustable vanes to optimize air flow and compression based on the engine’s demand. This dynamic interaction allows the engine to operate efficiently across a broader range of conditions, from idle to full throttle.

Mounting and Connection Considerations

Proper mounting and connection of the impeller within the turbocharger housing are essential for its effective operation. Whether in a Turbocharger and Mounting setup or a Turbocharger and Connection system, ensuring that the impeller is securely and correctly installed will prevent issues such as air leaks and inefficient compression, thereby maintaining the engine’s performance and reliability.

Conclusion

The 3002731 Turbocharger Compressor Impeller is a critical component in enhancing the performance and efficiency of Cummins engines. Its role in compressing intake air, integrating with turbocharger systems, and contributing to various engine setups underscores its importance in modern engine technology. Regular maintenance and proper installation are essential to ensure the impeller operates at peak efficiency, thereby maintaining the engine’s power and fuel economy.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.