This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Inlet Connection (Part #3028870) by Cummins is a specialized component designed to facilitate the flow of oil into the turbocharger system. This part is integral to the turbocharger’s operation, ensuring efficient lubrication and cooling. Manufactured by Cummins, a renowned name in the commercial truck industry, this component is engineered to meet the demanding requirements of heavy-duty applications 1.

Basic Concepts of Turbocharger Oil Inlet Connection

To understand the role of the Turbocharger Oil Inlet Connection, it is important to first grasp the fundamental principles of turbochargers. A turbocharger is a device that increases an engine’s efficiency and power output by forcing extra air into the combustion chamber. This process, known as forced induction, allows more fuel to be burned, resulting in greater power production without a corresponding increase in engine size 2.

The oil inlet connection plays a specific role in this system by providing a pathway for oil to enter the turbocharger. This oil is crucial for lubricating the turbocharger’s moving parts, such as the turbine and compressor wheels, and for cooling these components to prevent overheating. Effective lubrication and cooling are vital for the turbocharger’s performance and longevity 3.

Purpose of the Turbocharger Oil Inlet Connection

The Turbocharger Oil Inlet Connection (Part #3028870) serves a pivotal role in the operation of a truck’s engine. Its primary function is to deliver oil to the turbocharger, ensuring that the internal components are adequately lubricated and cooled. This connection helps maintain the turbocharger’s efficiency by reducing friction between moving parts and dissipating heat generated during operation. Proper lubrication and cooling are essential for the turbocharger to function optimally and to extend its service life.

Key Features

The Turbocharger Oil Inlet Connection is designed with several key features that enhance its performance and durability. Constructed from high-quality materials, this component is built to withstand the high pressures and temperatures associated with turbocharger operation. Its design includes precise fittings and seals to ensure a secure and leak-free connection. Additionally, the connection is engineered to accommodate the specific flow rates and pressures required by the turbocharger system, ensuring efficient oil delivery.

Benefits

The Turbocharger Oil Inlet Connection offers several advantages that contribute to improved engine performance and reliability. By ensuring consistent oil flow to the turbocharger, this component helps maintain optimal lubrication and cooling, which in turn enhances the turbocharger’s efficiency and longevity. Reliable operation of the oil inlet connection under various operating conditions also contributes to overall engine efficiency and performance.

Installation and Integration

Proper installation of the Turbocharger Oil Inlet Connection is crucial for ensuring its effective function within the turbocharger system. Installation should be performed according to the manufacturer’s guidelines, which may include specific torque settings for fittings and verification of seal integrity. It is important to ensure that the connection is properly aligned and secured to prevent leaks and maintain efficient oil flow. Any necessary preparations, such as cleaning the installation area and inspecting for damage, should be completed before installation.

Troubleshooting and Maintenance

Regular maintenance and timely troubleshooting are important for ensuring the Turbocharger Oil Inlet Connection operates effectively throughout its service life. Common issues may include leaks, blockages, or wear on fittings and seals. Routine inspections should be conducted to check for signs of damage or wear. Maintenance practices may include cleaning the connection and surrounding areas, inspecting seals for integrity, and ensuring that all fittings are secure. Addressing issues promptly can help prevent more significant problems and ensure continued reliable performance.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and turbochargers. With a history spanning over a century, Cummins has established a strong reputation for quality, reliability, and innovation in the commercial truck industry. The company’s turbocharger components, including the Turbocharger Oil Inlet Connection, are designed to meet the rigorous demands of heavy-duty applications, providing customers with reliable and efficient power solutions.

Turbocharger Oil Inlet Connection (Part 3028870) Compatibility with Cummins Engines

The Turbocharger Oil Inlet Connection (part 3028870) is a crucial component in ensuring the proper lubrication and operation of turbochargers in various Cummins engines. This part is designed to fit seamlessly with several engine models, providing a reliable connection for oil supply to the turbocharger.

Compatibility with Specific Engine Models

6C8.3 The 6C8.3 engine benefits from the Turbocharger Oil Inlet Connection, ensuring that the turbocharger receives the necessary oil for optimal performance and longevity.

ISM CM570 In the ISM CM570 engine, this part is essential for maintaining the turbocharger’s efficiency and reliability, contributing to the engine’s overall performance.

L10 GAS and L10 MECHANICAL Both the L10 GAS and L10 MECHANICAL engines are designed to use the Turbocharger Oil Inlet Connection. This part ensures that the turbocharger operates smoothly, reducing wear and tear and enhancing the engine’s efficiency.

M11 CELECT PLUS The M11 CELECT PLUS engine also relies on the Turbocharger Oil Inlet Connection to provide the necessary oil flow to the turbocharger, ensuring it functions correctly and extends the engine’s lifespan.

QSC8.3 CM850 (CM2850) The QSC8.3 CM850 (CM2850) engine is another model that utilizes the Turbocharger Oil Inlet Connection. This part is critical for maintaining the turbocharger’s performance and ensuring the engine operates at peak efficiency.

By integrating the Turbocharger Oil Inlet Connection into these engines, Cummins ensures that the turbochargers receive the proper lubrication, which is vital for their operation and longevity. This part is a testament to Cummins’ commitment to providing high-quality, reliable components for their engines.

Understanding the Role of Part 3028870 Turbocharger Oil Inlet Connection

In the context of engine systems, the turbocharger oil inlet connection, specifically part 3028870, serves as a vital interface within the turbocharger assembly. This component is integral to the efficient operation of the turbocharger, ensuring that lubrication is properly delivered to the turbocharger’s moving parts.

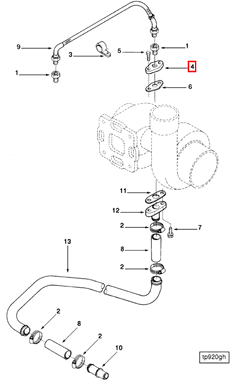

Integration with Turbocharger Plumbing

The turbocharger oil inlet connection is a key element in the turbocharger’s plumbing system. It is designed to connect the oil supply line to the turbocharger, allowing pressurized oil to flow into the turbocharger’s bearing and turbine housing. This lubrication is essential for reducing friction and wear on the turbocharger’s components, thereby enhancing its longevity and performance.

Relationship with Turbocharger Arrangement

In the overall turbocharger arrangement, part 3028870 plays a significant role. It is strategically positioned to facilitate the smooth flow of oil into the turbocharger. The proper installation and sealing of this connection are important for maintaining the integrity of the oil supply system, preventing leaks, and ensuring that the turbocharger receives a consistent flow of lubricant.

Impact on Turbocharger Performance

The effectiveness of the turbocharger oil inlet connection directly influences the turbocharger’s performance. By ensuring a reliable oil supply, this component helps maintain optimal operating temperatures and reduces the risk of turbocharger failure due to inadequate lubrication. It is a part of the system that works in conjunction with other components to enhance the turbocharger’s efficiency and reliability.

Conclusion

Understanding the role of part 3028870 in the turbocharger system highlights its importance in maintaining the turbocharger’s performance and longevity. Its integration within the turbocharger plumbing and arrangement underscores the necessity for precise installation and maintenance to ensure the turbocharger operates at peak efficiency.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.