This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

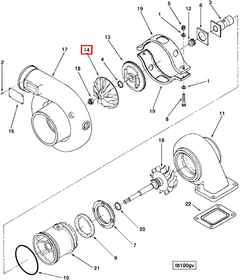

The Cummins 3031980 Turbocharger Compressor Impeller is a vital component in the turbocharger system of commercial trucks. Its purpose is to enhance the engine’s performance by increasing the airflow into the combustion chamber, which in turn boosts power output and efficiency. Understanding its significance and function is key to maintaining and optimizing the performance of commercial trucks.

Basic Concepts of Turbocharger Compressor Impellers

Turbocharger compressor impellers operate on the principle of compressing intake air before it enters the engine. This is achieved by spinning the impeller at high speeds, driven by exhaust gases. The compressed air increases the oxygen content in the combustion chamber, allowing for more efficient fuel combustion and greater power output. The efficiency and design of the impeller are critical to the overall performance of the turbocharger system 1.

Role of the 3031980 Turbocharger Compressor Impeller in Truck Operation

The 3031980 Turbocharger Compressor Impeller plays a significant role in enhancing engine performance and efficiency in commercial trucks. By increasing the density of the intake air, it allows the engine to burn more fuel per cycle, resulting in higher power output. Additionally, the improved airflow contributes to better fuel efficiency, making it a valuable component for trucks that require both power and economy 2.

Key Features of the 3031980 Turbocharger Compressor Impeller

The 3031980 Turbocharger Compressor Impeller is designed with several notable characteristics that enhance its effectiveness and durability. These include precision-machined blades that ensure optimal airflow and efficiency, robust materials that withstand high temperatures and pressures, and a balanced design that minimizes vibrations and wear. These features contribute to the impeller’s reliability and longevity in demanding commercial truck applications.

Benefits of Using the 3031980 Turbocharger Compressor Impeller

Incorporating the 3031980 Turbocharger Compressor Impeller into a truck’s engine system offers several advantages. These include improved power output, enhanced fuel efficiency, and increased reliability. The impeller’s design allows for better airflow and combustion, resulting in a more powerful and efficient engine. Additionally, its durable construction ensures long-term performance and reduced maintenance requirements.

Installation and Integration

Proper installation and integration of the 3031980 Turbocharger Compressor Impeller are important for ensuring optimal performance. It is designed to be compatible with various engine models and configurations, but it is important to follow manufacturer guidelines to ensure correct fitting and operation. This includes verifying compatibility, using the appropriate tools and techniques for installation, and conducting thorough testing post-installation to confirm proper function.

Performance Optimization

To maximize the performance of the 3031980 Turbocharger Compressor Impeller, several strategies and techniques can be employed. These include fine-tuning the engine’s air-fuel ratio, ensuring the turbocharger system is free of leaks, and maintaining the impeller in optimal condition through regular cleaning and inspection. Additionally, adhering to recommended maintenance schedules and operational best practices will help sustain peak performance.

Troubleshooting Common Issues

Common problems associated with the 3031980 Turbocharger Compressor Impeller can include issues such as reduced efficiency, unusual noises, or physical damage to the impeller. Diagnostic procedures may involve inspecting the impeller for signs of wear or damage, checking for proper turbocharger system operation, and ensuring the engine’s air-fuel ratio is correctly balanced. Repair techniques may range from cleaning and rebalancing the impeller to replacement in cases of severe damage.

Maintenance and Care

Routine maintenance and care of the 3031980 Turbocharger Compressor Impeller are important for ensuring optimal performance and longevity. This includes regular cleaning to remove any buildup that may impede airflow, periodic inspection for signs of wear or damage, and following manufacturer-recommended replacement schedules. Proper maintenance will help prevent performance issues and extend the lifespan of the impeller.

Cummins Corporation

Cummins Corporation is a well-established manufacturer with a strong reputation in the commercial truck industry. Founded in 1919, the company has a long history of producing high-quality engine and powertrain components. Cummins is known for its commitment to innovation, reliability, and customer satisfaction, making it a trusted name among commercial truck operators and maintenance professionals.

Cummins Turbocharger Compressor Impeller Part 3031980

The Cummins turbocharger compressor impeller part number 3031980 is a critical component in the turbocharger system of various NH/NT 855 engines. This part is designed to efficiently compress incoming air, which is then delivered to the engine’s combustion chamber. The compressor impeller is responsible for increasing the pressure of the air, thereby enhancing the engine’s power output and efficiency.

The NH/NT 855 engines, known for their robust performance and reliability, benefit significantly from the use of high-quality turbocharger components like the 3031980 impeller. This part ensures that the turbocharger operates smoothly, providing consistent performance across a range of operating conditions.

In the NH/NT 855 engine family, the turbocharger compressor impeller part 3031980 is engineered to fit seamlessly with the engine’s design, ensuring optimal integration and performance. The precision engineering of this component is crucial for maintaining the integrity of the turbocharger system, which in turn supports the overall efficiency and longevity of the engine.

For the NH/NT 855 engines, the use of the 3031980 turbocharger compressor impeller is essential for achieving the desired performance characteristics. This part is integral to the turbocharger’s function, ensuring that the engine can deliver the power and efficiency expected by users in demanding applications.

Understanding the Integration of Part 3031980 Turbocharger Compressor Impeller in Engine Systems

The part 3031980 turbocharger compressor impeller is a specialized component designed to enhance the performance of various engine systems. Its role is significant in the operation of the turbocharger, which is a key element in modern high-performance engines.

Role in Performance Parts

When integrated into performance parts, the 3031980 impeller contributes to increased airflow efficiency. This results in better engine breathing, allowing for higher power outputs and improved throttle response. The impeller’s design ensures that air is compressed more effectively, which is essential for maximizing the potential of aftermarket performance modifications.

Function within Standard 50 W/Brake Turbocharger

In a standard 50 W/brake turbocharger setup, the 3031980 impeller plays a vital role in maintaining the balance between power and efficiency. It ensures that the turbocharger can handle the increased airflow demands without compromising the engine’s reliability. This component is engineered to work seamlessly with the turbocharger’s housing and other internal components, optimizing the overall performance of the system.

Importance in Turbocharger Assemblies

Within a turbocharger assembly, the 3031980 impeller is responsible for compressing the intake air before it enters the engine’s combustion chambers. This compression increases the air density, allowing more fuel to be burned and thus generating more power. The impeller’s precise engineering ensures that it can withstand the high speeds and temperatures associated with turbocharger operation, contributing to the durability and efficiency of the entire system.

Integration with Turbocharger and Mounting

When considering the turbocharger and its mounting, the 3031980 impeller must be correctly aligned and secured. Proper installation ensures that the impeller can spin freely without any obstructions, which is essential for maintaining the turbocharger’s efficiency. The mounting system must be robust enough to handle the forces generated by the impeller’s high-speed rotation, ensuring that the turbocharger remains stable and operational under all driving conditions.

Contribution to Turbocharger Kits

In a turbocharger kit, the 3031980 impeller is often a highlighted component due to its impact on the kit’s overall performance. Turbocharger kits are designed to provide a comprehensive upgrade to an engine’s airflow system, and the impeller is a key part of this upgrade. Its inclusion in the kit ensures that users can achieve significant performance gains, making it a valuable addition for enthusiasts looking to enhance their engine’s capabilities.

Conclusion

The Cummins 3031980 Turbocharger Compressor Impeller is a critical component for enhancing the performance and efficiency of commercial truck engines. Its precise engineering, durable construction, and optimal integration within the turbocharger system make it a valuable asset for truck operators and maintenance professionals. Proper installation, maintenance, and care are essential for ensuring the longevity and reliability of this Cummins part, ultimately contributing to the overall performance and efficiency of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.