This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Turbocharger Oil Drain Connection (3408202) by Cummins is a specialized component designed for use in heavy-duty truck engines. Its purpose is to facilitate the drainage of oil from the turbocharger, ensuring that the system operates efficiently and maintains optimal performance. This part is integral to the turbocharger system, contributing to the overall reliability and effectiveness of the engine 1.

Basic Concepts

Turbochargers operate by compressing the air entering the engine, which allows for more fuel to be burned and thus increases power output. To function correctly, turbochargers require lubrication, typically provided by engine oil. The oil drainage system is necessary to remove excess oil and contaminants that could otherwise impair turbocharger performance. The Turbocharger Oil Drain Connection plays a role in this system by providing a pathway for oil to exit the turbocharger, ensuring that only a necessary amount of oil remains for lubrication 2.

Purpose and Function

The Turbocharger Oil Drain Connection is designed to maintain the correct oil level within the turbocharger. By allowing excess oil to drain away, it helps prevent oil buildup, which can lead to increased temperatures and reduced efficiency. This component aids in sustaining optimal turbocharger performance and longevity by ensuring that the turbocharger operates within its designed parameters 3.

Key Features

The 3408202 Turbocharger Oil Drain Connection is characterized by several design elements that enhance its functionality. It is constructed from durable materials to withstand the high temperatures and pressures present in the turbocharger system. The connection is engineered to provide a secure seal, preventing oil leaks that could lead to contamination or loss of lubrication. Additionally, it is designed for easy installation and maintenance, facilitating quick access for draining and inspection.

Benefits

The Turbocharger Oil Drain Connection offers several advantages. It contributes to improved engine efficiency by ensuring that the turbocharger operates with the correct amount of oil. This can lead to reduced maintenance requirements, as proper oil management helps prevent wear and damage to the turbocharger. Furthermore, the connection enhances the overall performance of the turbocharger system, potentially leading to better fuel efficiency and power output.

Installation and Compatibility

Proper installation of the Turbocharger Oil Drain Connection involves following manufacturer guidelines to ensure a secure and leak-free connection. It is compatible with various Cummins engine models, designed to integrate seamlessly with the turbocharger system. Users should consult specific compatibility charts and installation instructions provided by Cummins to ensure correct application.

Maintenance and Troubleshooting

Routine maintenance of the Turbocharger Oil Drain Connection includes regular inspection for signs of wear or damage, and ensuring that the connection remains secure and free of leaks. Troubleshooting common issues may involve checking for proper oil levels within the turbocharger and verifying that the drain connection is functioning correctly. If issues arise, such as oil leaks or reduced performance, it may be necessary to clean or replace the connection to restore optimal function.

Performance Impact

The Turbocharger Oil Drain Connection influences the performance of the turbocharger by ensuring that oil levels are maintained within the designed parameters. This can lead to improvements in fuel efficiency, as the turbocharger operates more effectively. Additionally, proper oil management can enhance power output and contribute to the durability of the turbocharger system, reducing the likelihood of premature failure.

Safety Considerations

When working with the Turbocharger Oil Drain Connection, it is important to observe safety protocols and precautions. This includes ensuring that the engine is cool before attempting any maintenance or installation procedures. Adhering to manufacturer guidelines and industry standards is crucial to prevent accidents and ensure the safe operation of the turbocharger system.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive industry, known for its innovative and high-quality components. With a rich history of producing reliable and efficient engines and parts, Cummins has established a strong reputation for excellence. The company’s commitment to innovation is evident in its product range, which includes a variety of components designed to enhance the performance and reliability of heavy-duty trucks.

Role of Part 3408202 Turbocharger Oil Drain Connection in Engine Systems

The turbocharger oil drain connection, identified by part number 3408202, is an integral component in the maintenance and operation of turbocharged engine systems. This part facilitates the drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters.

Integration with Turbocharger

In turbocharged engines, the turbocharger itself is a high-speed component that requires consistent lubrication to reduce friction and wear. The oil drain connection plays a significant role by allowing the used oil to be efficiently removed from the turbocharger housing. This process helps in maintaining the oil’s quality, preventing contamination, and ensuring that the turbocharger continues to perform at peak efficiency.

Connection to Plumbing Systems

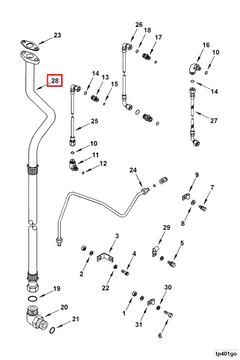

The turbocharger oil drain connection is also a key interface point within the engine’s plumbing system. It connects to the oil return lines, which transport the drained oil back to the sump or oil pan. This ensures a closed-loop system where the oil is continuously circulated, filtered, and re-lubricated. The proper functioning of this connection is essential for maintaining the integrity of the oil supply system and preventing any potential leaks that could lead to oil starvation or contamination.

Maintenance and Operational Efficiency

Regular maintenance of the turbocharger oil drain connection is vital. Over time, deposits and contaminants can accumulate, potentially obstructing the drain path. Ensuring that this connection remains clear and functional is important for the longevity and performance of the turbocharger. During maintenance checks, engineers and mechanics should verify the tightness and condition of the connection to prevent any oil leaks, which could lead to decreased lubrication efficiency and increased wear on the turbocharger components.

Summary of Component Interaction

- Turbocharger: The primary component that relies on consistent oil drainage to maintain lubrication and operational efficiency.

- Plumbing System: The network of oil lines and connections that transport oil to and from the turbocharger, with the drain connection being a critical juncture in this system.

Understanding the role of part 3408202 in these systems highlights its importance in the overall health and performance of turbocharged engines. Proper installation and maintenance of this component contribute significantly to the engine’s reliability and efficiency.

Conclusion

The Turbocharger Oil Drain Connection (3408202) by Cummins is a critical component in the efficient operation of turbocharged engine systems. By ensuring proper oil drainage, it maintains optimal turbocharger performance, enhances engine efficiency, and contributes to the longevity of the engine. Regular maintenance and adherence to safety protocols are essential for maximizing the benefits of this part.

-

Bennett, S. (2012). Modern Diesel Technology: Light Duty Diesels. Cengage Learning.

↩ -

Duffy, O. C., & Wright, G. (2016). Fundamentals of Medium-Heavy Duty Commercial Vehicle Systems. Jones Bartlett Learning.

↩ -

Han, Z. (2022). Simulation and Optimization of Internal Combustion Engines. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.