This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3519489 Turbocharger Compressor Impeller is designed to enhance the performance of heavy-duty truck engines. It increases the efficiency of the turbocharger system, thereby improving the overall operation of the engine. This part is integral to maintaining high performance standards in heavy-duty trucking applications.

Basic Concepts of Turbocharger Compressor Impellers

A turbocharger compressor impeller is a rotating component within a turbocharger that compresses intake air before it enters the engine’s combustion chamber. This compression increases air density, allowing more oxygen to be available for combustion. The result is enhanced engine performance, as the increased oxygen supports more efficient fuel burning and greater power output 1.

Purpose and Role in Truck Operation

This Cummins part is specifically engineered to fit within the turbocharger systems of heavy-duty trucks. Its purpose is to facilitate improved airflow into the engine, which enhances combustion efficiency. By compressing the intake air, the impeller ensures that the engine receives a denser air charge, leading to more complete combustion and better overall engine performance. This is particularly beneficial in heavy-duty applications where maximizing engine efficiency and power is crucial.

Key Features

The Turbocharger Compressor Impeller is characterized by its precision-engineered design and the use of high-quality materials. These features ensure durability and efficiency. The impeller’s design allows for optimal air compression, while the materials used are selected for their ability to withstand the high stresses and temperatures encountered in heavy-duty engine environments. Additionally, the impeller may feature unique characteristics such as a specific blade geometry that enhances its performance capabilities.

Benefits

Utilizing the Cummins 3519489 offers several advantages. These include increased power output due to more efficient air compression, improved fuel efficiency as a result of better combustion, and enhanced durability thanks to the high-quality materials and design. These benefits contribute to the overall reliability and performance of heavy-duty truck engines.

Installation and Compatibility

Proper installation of the Turbocharger Compressor Impeller is crucial for ensuring its effectiveness and longevity. Installation procedures should follow manufacturer guidelines to avoid damage and ensure optimal performance. This part is compatible with specific Cummins engine models, designed to fit seamlessly within their turbocharger systems.

Troubleshooting and Maintenance

Regular maintenance and troubleshooting are important for the Turbocharger Compressor Impeller to ensure it operates at peak efficiency. Common issues may include decreased performance or unusual noises, which can often be traced back to improper installation, wear and tear, or contamination. Regular inspections and cleaning can help prevent these issues, ensuring the impeller continues to function effectively.

Performance Enhancements

The Turbocharger Compressor Impeller can significantly contribute to performance enhancements in heavy-duty trucks. By improving the efficiency of the turbocharger system, it allows for increased horsepower and torque, leading to better overall drivability and engine responsiveness. This makes it a valuable component for truck operators looking to maximize their vehicle’s performance.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a strong reputation in the automotive industry, Cummins is known for its commitment to innovation and quality. The company’s extensive history and dedication to excellence in manufacturing automotive components underscore its position as a trusted provider of high-performance parts like the Cummins 3519489.

Compatibility with Cummins Engines

The Turbocharger Compressor Impeller, identified by part number 3519489 and manufactured by Cummins, is designed to work seamlessly with various Cummins engines, ensuring optimal performance and efficiency.

N14 MECHANICAL

The N14 MECHANICAL engine is a robust and reliable power unit, often utilized in heavy-duty applications. The Turbocharger Compressor Impeller (3519489) is specifically engineered to fit this engine model. Its design ensures efficient air compression, which is vital for enhancing the engine’s power output and overall performance. The impeller’s precision engineering guarantees a perfect fit, allowing for smooth operation and longevity of the turbocharger system.

Group Compatibility

In addition to the N14 MECHANICAL engine, the Turbocharger Compressor Impeller (3519489) is compatible with other Cummins engine groups that utilize similar turbocharger configurations. This part’s versatility makes it a valuable component for maintaining and upgrading various Cummins engines, ensuring they operate at peak efficiency. The compatibility extends to engines that share similar design parameters and operational requirements, providing a reliable solution for turbocharger maintenance and replacement.

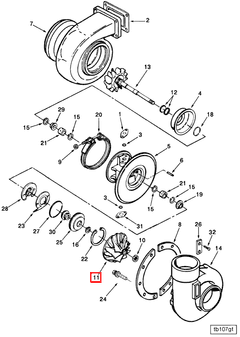

Understanding the Integration of Part 3519489 in Engine Systems

The part 3519489 turbocharger compressor impeller is a specialized component that enhances the functionality of various engine systems by improving airflow and efficiency. When integrated into an aftermarket turbocharger, this impeller plays a significant role in increasing the volume of air that enters the engine, thereby boosting power output and performance.

In the context of a core assembly, the impeller works in conjunction with the turbine and compressor housings to maintain a balanced airflow. This ensures that the compressed air is delivered efficiently to the engine’s intake system, optimizing combustion and overall engine performance.

For the core assembly HT3B (DCM), the impeller’s design is tailored to fit precisely within the turbocharger’s compressor wheel. This fitment is essential for maintaining the integrity of the air-fuel mixture, which is vital for the engine’s power delivery and thermal efficiency.

When considering the Heat3B turbocharger, the impeller’s role becomes even more pronounced. The Heat3B turbocharger is known for its high-performance capabilities, and the impeller’s efficient design helps in managing the increased airflow demands, ensuring that the turbocharger operates within its optimal range.

In the realm of performance parts, the impeller is often upgraded to handle higher airflow rates, which is essential for engines that have been modified for increased power. This upgrade ensures that the turbocharger can keep up with the demands of a high-performance engine, providing the necessary boost without compromising reliability.

Within a comprehensive turbocharger kit, the impeller is a key component that dictates the kit’s overall performance. The kit typically includes various parts designed to work in harmony, and the impeller’s efficiency directly influences the turbocharger’s ability to deliver consistent and reliable boost pressure.

Overall, the part 3519489 turbocharger compressor impeller is an integral component that enhances the performance and efficiency of various engine systems, ensuring that the turbocharger operates at peak efficiency.

Conclusion

The Cummins 3519489 Turbocharger Compressor Impeller is a critical component for enhancing the performance and efficiency of heavy-duty truck engines. Its precision-engineered design, high-quality materials, and compatibility with specific Cummins engine models make it a valuable asset for truck operators. Regular maintenance and proper installation are essential for ensuring the impeller operates at peak efficiency, contributing to the overall reliability and performance of the engine.

-

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.