This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

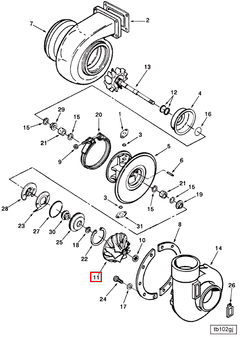

The Turbocharger Compressor Impeller 3520775, manufactured by Cummins, is a critical component in the automotive industry, particularly for diesel engines. This part enhances engine performance and efficiency in heavy-duty truck engines.

Basic Concepts of Turbocharger Compressor Impellers

Turbochargers increase an engine’s power output by forcing extra air into the combustion chamber. The compressor impeller, a rotating disc with blades, plays a key role in this process. As it spins, it draws in and compresses air before it enters the engine, allowing for more efficient combustion and increased power 1.

Role of the 3520775 Turbocharger Compressor Impeller in Truck Operation

This Cummins part enhances the air intake process by compressing incoming air, leading to more efficient combustion. This results in better engine performance, increased power output, and reduced emissions, aligning with environmental standards 2.

Key Features of the 3520775 Turbocharger Compressor Impeller

The 3520775 is constructed from high-quality materials for durability and resistance to wear. Its precisely engineered blades optimize air compression, and its design meets the demanding requirements of heavy-duty truck engines, ensuring reliable performance under various conditions 3.

Benefits of Using the 3520775 Turbocharger Compressor Impeller

Using this part offers advantages such as improved engine performance, increased power output, better engine efficiency, and durability. Its efficient combustion design also contributes to improved fuel efficiency, reducing operating costs for truck operators.

Troubleshooting Common Issues with Turbocharger Compressor Impellers

Common issues with turbocharger compressor impellers include imbalance, fouling, and wear. Imbalance can cause vibrations and reduced efficiency, while fouling occurs when contaminants build up on the impeller blades, affecting performance. Wear is a natural consequence of prolonged use and can lead to decreased efficiency over time. Regular inspections and maintenance can help mitigate these issues.

Maintenance Practices for Turbocharger Compressor Impellers

Routine maintenance is essential for the optimal performance and longevity of turbocharger compressor impellers. This includes regular inspections for signs of wear, imbalance, or fouling, and cleaning the impeller to remove contaminants. In cases of wear or damage, replacement may be necessary to maintain engine efficiency and performance. Following manufacturer guidelines for maintenance intervals and procedures is recommended.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. The company’s product offerings extend beyond engines to include filtration, emissions solutions, and powertrain-related components, making it a comprehensive provider of power solutions for various applications, including heavy-duty trucks.

Understanding the Role of Part 3520775 Turbocharger Compressor Impeller in Engine Systems

The 3520775 turbocharger compressor impeller is a key component in enhancing the performance of various engine systems, particularly when integrated with aftermarket turbochargers and performance parts.

When installed in an aftermarket turbocharger, the impeller works in conjunction with the turbocharger’s assembly core to increase the airflow into the engine. This results in improved combustion efficiency and higher power output. The impeller’s design allows it to spin at high speeds, compressing the intake air before it enters the engine’s cylinders.

In the context of EBM (Engine Build Mastery) parts and EBM turbochargers, the impeller is essential for achieving the desired performance gains. It ensures that the compressed air is delivered at the optimal pressure and temperature, which is vital for maximizing engine efficiency and power.

For those looking to upgrade with performance parts, the impeller’s role becomes even more significant. It is often one of the first components to be upgraded in a turbocharger kit to handle the increased airflow demands of a modified engine. This upgrade allows the engine to breathe more freely, supporting higher boost levels and overall performance.

Conclusion

The 3520775 turbocharger compressor impeller is integral to the function and performance of turbochargers, whether in stock form or as part of a high-performance build. Its efficient design and robust construction make it a fundamental component in any turbocharged engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.