This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

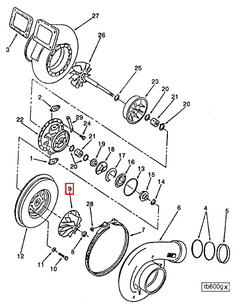

The Turbocharger Compressor Impeller 3523024, manufactured by Cummins, is designed to enhance the performance of heavy-duty truck engines. This part increases engine efficiency by compressing intake air before it enters the combustion chamber, allowing for a more powerful and efficient combustion process 1.

Basic Concepts of Turbocharger Compressor Impellers

Turbocharger compressor impellers operate by compressing air to increase its density before it enters the engine’s combustion chambers. This is achieved through the rotation of the impeller, driven by exhaust gases. As the impeller spins, it draws in ambient air and accelerates it, increasing its pressure and density. This compressed air is then delivered to the engine, allowing for a greater amount of fuel to be burned in each cycle, which enhances power output and efficiency 2.

Role of the 3523024 Turbocharger Compressor Impeller in Truck Operation

This Cummins part plays a specific role in enhancing engine performance and efficiency in heavy-duty trucks. By compressing the intake air, it allows the engine to burn more fuel per cycle, increasing power output. Additionally, the improved air density leads to more efficient combustion, which can result in better fuel economy. This component is integral to the turbocharger system, working in conjunction with the turbine and other components to optimize engine performance under various operating conditions 3.

Key Features of the 3523024 Turbocharger Compressor Impeller

The 3523024 is distinguished by several primary characteristics and design elements. It is constructed from high-strength materials to withstand the high-stress environment of a turbocharger. The impeller features a precise blade design that maximizes air compression efficiency. Additionally, its construction includes advanced manufacturing techniques to ensure durability and reliability. Unique attributes may include specific blade angles and aerodynamic profiles tailored to optimize performance in heavy-duty truck applications.

Benefits of Using the 3523024 Turbocharger Compressor Impeller

Incorporating this part into a truck’s engine system offers several advantages. These include improved power output, as the increased air density allows for more fuel to be burned, resulting in greater horsepower and torque. Fuel efficiency is also enhanced, as the optimized combustion process reduces the amount of fuel needed for a given power output. Overall performance is improved, with better throttle response and reduced turbo lag, making the truck more responsive and efficient in various driving conditions.

Troubleshooting and Maintenance Suggestions

To ensure the optimal performance and longevity of the 3523024, regular maintenance and troubleshooting are recommended. Common issues may include impeller fouling, which can reduce efficiency, and wear on the impeller blades. Regular inspection and cleaning of the impeller can help prevent these issues. Additionally, ensuring that the turbocharger system is free from leaks and that the impeller is properly lubricated can contribute to its longevity. If performance issues arise, such as reduced power output or unusual noises, a thorough inspection of the impeller and associated components is advised.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for producing high-quality components that are reliable and efficient. The company is committed to innovation and sustainability, continually advancing its product offerings to meet the evolving needs of the automotive industry. The 3523024 is a testament to Cummins’ dedication to excellence in component manufacturing.

Turbocharger Compressor Impeller Compatibility with Cummins Engines

The turbocharger compressor impeller part number 3523024, manufactured by Cummins, is designed to enhance the efficiency and performance of specific Cummins engines. This part is integral to the turbocharger system, which improves engine power and responsiveness by forcing more air into the combustion chamber.

Cummins K19 Engine

For the Cummins K19 engine, the turbocharger compressor impeller part number 3523024 is engineered to fit seamlessly within the turbocharger assembly. This engine is known for its robust design and high performance, making it suitable for heavy-duty applications. The impeller’s precise fit ensures optimal airflow and pressure, contributing to the engine’s overall efficiency and power output.

Cummins K38 Engine

Similarly, the Cummins K38 engine benefits from the turbocharger compressor impeller part number 3523024. This engine is designed for durability and reliability, often used in demanding environments. The impeller’s compatibility with the K38 engine ensures that it can handle the specific airflow requirements, enhancing the engine’s performance and longevity.

Grouping of Engines

Both the K19 and K38 engines share common design principles and performance characteristics, making the turbocharger compressor impeller part number 3523024 a versatile component for these engines. Cummins has ensured that this part meets the stringent requirements of both engine models, providing a reliable and efficient solution for turbocharger performance.

Understanding the Role of Part 3523024 Turbocharger Compressor Impeller in Engine Systems

The Turbocharger Compressor Impeller is a pivotal component within various engine systems, especially when integrated with aftermarket turbochargers and performance parts. Its function is to enhance the efficiency and power output of the engine by compressing the intake air before it enters the combustion chamber.

When installed in an aftermarket turbocharger, the impeller works in conjunction with the turbine to increase the volume of air entering the engine. This results in a denser air charge, which, when mixed with fuel, leads to more powerful combustion and thus, greater engine performance.

In the context of a core assembly or a core assembly HC5A, the impeller is a fundamental part that ensures the turbocharger operates at optimal efficiency. The core assembly houses the impeller, turbine, and other critical components, and the impeller’s role is to spin at high speeds, driven by the exhaust gases, to compress the intake air.

For those working with a turbo T18A KV12 or similar turbocharger models, the impeller’s design and material are tailored to handle the specific airflow and pressure requirements of these units. The impeller’s precision engineering allows it to withstand high rotational speeds and temperatures, ensuring reliable performance under demanding conditions.

In a turbocharger kit, the impeller is often one of the high-performance components included to upgrade the engine’s capabilities. These kits are designed to provide a comprehensive solution for enhancing engine power, and the impeller is a key element in achieving the desired performance gains.

Overall, the Turbocharger Compressor Impeller is an essential component that, when properly integrated with the turbocharger and engine system, significantly contributes to improved engine efficiency, power, and overall performance.

Conclusion

The 3523024 Turbocharger Compressor Impeller by Cummins is a critical component for enhancing the performance and efficiency of heavy-duty truck engines. Its role in compressing intake air leads to improved power output, fuel efficiency, and overall engine performance. Regular maintenance and proper integration with the turbocharger system are essential for maximizing the benefits of this part.

-

Happian-Smith, Julian. An Introduction to Modern Vehicle Design. Butterworth-Heinemann, 2002.

↩ -

Gilles, Tim. Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning, 2020.

↩ -

Dixon, John. Modern Diesel Technology: Heating, Ventilation, Air Conditioning, Refrigeration, 2nd Edition. Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.