This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

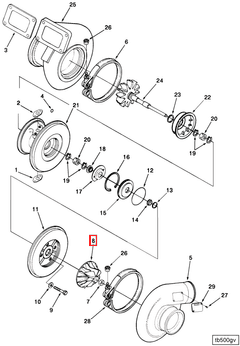

The Cummins 3523592 Turbocharger Compressor Impeller is engineered to enhance the performance of commercial truck engines. It increases the efficiency of the turbocharger system by compressing intake air before it enters the engine’s combustion chamber. This part significantly contributes to improved engine performance and fuel efficiency in commercial trucks.

Basic Concepts of Turbocharger Compressor Impellers

Turbocharger compressor impellers operate by compressing intake air to increase its density. This compressed air, when mixed with fuel, allows for more efficient combustion within the engine. The impeller, a rotating component within the turbocharger, draws in ambient air and accelerates it through a series of blades. As the air passes through these blades, it is compressed and directed into the engine, enhancing the overall efficiency of the combustion process 1.

Role of the 3523592 Turbocharger Compressor Impeller in Truck Operation

The 3523592 Turbocharger Compressor Impeller is integral to the performance and efficiency of commercial truck engines. By compressing the intake air, it allows for a greater amount of oxygen to enter the combustion chamber. This increased oxygen content supports more complete fuel combustion, leading to enhanced engine power and efficiency. The impeller’s design ensures that the air is compressed effectively, contributing to the overall performance of the turbocharger system 2.

Key Features of the 3523592 Turbocharger Compressor Impeller

The design and construction of the 3523592 Turbocharger Compressor Impeller are tailored to ensure effectiveness and durability. It features precision-engineered blades that optimize air compression, and its materials are selected for their strength and resistance to wear. These features contribute to the impeller’s ability to withstand the high-stress environment within a turbocharger, ensuring reliable performance over time 3.

Benefits of Using the 3523592 Turbocharger Compressor Impeller

Utilizing the 3523592 Turbocharger Compressor Impeller offers several advantages. It contributes to improved engine performance by enhancing the efficiency of the combustion process. This results in increased power output and better acceleration. Additionally, the impeller aids in achieving higher fuel efficiency, reducing operating costs for commercial truck fleets. Its robust design also ensures enhanced reliability, minimizing the need for frequent replacements 4.

Installation and Compatibility

Proper installation of the 3523592 Turbocharger Compressor Impeller is crucial for ensuring optimal performance. It is designed to be compatible with specific Cummins engine models, ensuring a seamless fit within the turbocharger system. Following manufacturer guidelines during installation helps maintain the integrity of the turbocharger and ensures the impeller functions as intended.

Maintenance and Troubleshooting

Regular maintenance of the 3523592 Turbocharger Compressor Impeller is important for sustaining its performance. This includes periodic inspections to check for wear or damage to the impeller blades. Cleaning the impeller to remove any buildup that could affect its efficiency is also recommended. Troubleshooting common issues, such as reduced engine performance or unusual noises from the turbocharger, may involve inspecting the impeller for signs of damage or imbalance.

Performance Enhancements

The 3523592 Turbocharger Compressor Impeller contributes to overall engine performance enhancements in commercial trucks. By improving the efficiency of the turbocharger system, it allows for more complete fuel combustion, leading to increased power output and better fuel economy. This enhancement is particularly beneficial for heavy-duty applications, where maximizing engine performance is critical.

Durability and Longevity

The durability and longevity of the 3523592 Turbocharger Compressor Impeller are influenced by several factors. The quality of materials used in its construction plays a role in withstanding the high-stress conditions within a turbocharger. Additionally, the design of the impeller, including the precision of the blades and the overall structure, contributes to its longevity. Regular maintenance and proper installation also help ensure the impeller remains in optimal condition over time.

Cummins: A Brief Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its commitment to innovation and quality in manufacturing commercial truck components. With a rich history of producing reliable and high-performance engines and parts, Cummins has established a reputation for excellence. The company’s dedication to advancing technology and improving efficiency in the commercial trucking sector underscores its position as a leader in the industry.

Integration with Cummins Engines

The 3523592 Turbocharger Compressor Impeller is engineered to work seamlessly with several Cummins engines, ensuring optimal air intake and pressure for improved combustion. This part is meticulously crafted to fit perfectly within the turbocharger assembly, ensuring smooth operation and longevity. The compatibility of this impeller with various Cummins engines highlights the versatility and high-quality standards of Cummins components.

Understanding the Integration of Part 3523592 Turbocharger Compressor Impeller in Engine Systems

The Part 3523592 Turbocharger Compressor Impeller is a specialized component that significantly enhances the performance of various engine systems. Its role is to compress the intake air before it enters the combustion chamber, thereby increasing the engine’s efficiency and power output.

Integration with Key Engine Components

- Aftermarket Turbocharger: Ensures optimal efficiency, resulting in improved airflow and increased boost pressure.

- Core Assembly and Core Assembly Heat4B: Maintains balanced airflow, vital for turbocharger functionality and durability.

- Cylinder Block: Allows for more efficient combustion, leading to better fuel economy and reduced emissions.

- EBM: Turbocharger: Achieves precise boost control, crucial for maintaining engine performance under varying conditions.

- Engine Piston Kit: Handles increased air pressure, ensuring pistons can withstand higher stresses without compromising durability.

- Main Bearing (Standard) Set: Supports the crankshaft, experiencing increased load due to higher air pressure. Proper lubrication and maintenance are essential.

- Overhaul Kit and Rebuild Kit: Ensures correct turbocharger system function post-overhaul, contributing to engine performance.

- Performance Parts: Often paired with other performance parts for significant improvements in power output and engine responsiveness.

- Short Block 6C, Short Block 6CART, and Short Block 6CTA: Ensures fine-tuned turbocharger system for desired balance between power and efficiency.

- Short Engine Kit and Turbocharger Kit: Ensures necessary boost pressure delivery, enhancing engine performance capabilities.

Conclusion

The Part 3523592 Turbocharger Compressor Impeller is integral to the efficient operation of various engine systems. Its proper integration with other components ensures optimal performance, durability, and efficiency. Regular maintenance and adherence to manufacturer guidelines during installation are essential for maximizing the benefits of this component.

-

Fischer, R., Kucukay, F., Jurgens, G., Najork, R., & Pollak, B. (2015). The Automotive Transmission Book Powertrain. Springer.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Gillespie, T. D. (2021). Fundamentals of Vehicle Dynamics. SAE International.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE International.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.