This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Turbocharger Compressor Impeller 3527047 is a component manufactured by Cummins, designed specifically for use in heavy-duty truck engines. This part is integral to the turbocharger system, which plays a significant role in enhancing engine performance by increasing the amount of air that enters the combustion chamber. The efficient operation of this impeller is vital for maintaining optimal engine efficiency and power output in demanding applications.

Basic Concepts of Turbocharger Compressor Impellers

Turbochargers are devices that use exhaust gases to drive a turbine, which in turn spins a compressor. The compressor draws in and compresses air before it enters the engine, allowing for more fuel to be burned and thus increasing power output. The compressor impeller is a key component within this system. It consists of a series of blades that spin at high speeds to compress the incoming air. This compressed air is then delivered to the engine’s intake system, facilitating a more complete combustion process and enhancing overall engine performance 1.

Purpose and Function of the 3527047 Turbocharger Compressor Impeller

The 3527047 Turbocharger Compressor Impeller is designed to improve the airflow into the engine of a heavy-duty truck. By increasing the volume and pressure of the air entering the combustion chamber, this impeller contributes to a more efficient burning of fuel, which translates to enhanced engine performance. Its role in the turbocharger system ensures that the engine receives a denser charge of air, which is crucial for achieving higher power outputs and improved fuel efficiency.

Key Features of the 3527047 Turbocharger Compressor Impeller

The 3527047 Turbocharger Compressor Impeller is characterized by its robust design and construction. It is made from high-quality materials that are resistant to wear and corrosion, ensuring durability under the demanding conditions of heavy-duty truck operation. The impeller features a precise blade design that optimizes airflow and efficiency. Its manufacturing process includes advanced techniques that enhance both performance and longevity, making it a reliable component for turbocharger systems.

Benefits of Using the 3527047 Turbocharger Compressor Impeller

Incorporating the 3527047 Turbocharger Compressor Impeller into a heavy-duty truck engine can lead to several advantages. These include improved engine performance due to increased air intake, enhanced fuel efficiency as a result of more complete combustion, and greater power output. The impeller’s design and construction contribute to these benefits by ensuring efficient operation of the turbocharger system under various driving conditions.

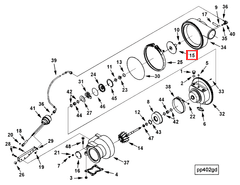

Installation and Integration

Proper installation of the 3527047 Turbocharger Compressor Impeller is crucial for ensuring optimal performance and compatibility with the engine. It is important to follow manufacturer guidelines for fitting and alignment to avoid issues that could affect engine efficiency. Compatibility with various engine models should be verified to ensure seamless integration into the turbocharger system.

Maintenance and Troubleshooting

Regular maintenance of the 3527047 Turbocharger Compressor Impeller is recommended to preserve its performance and longevity. This includes routine inspections for wear or damage, cleaning to remove any debris that could affect operation, and addressing common issues such as decreased efficiency or unusual noises promptly. Proper care and attention to this component can help maintain engine performance and reliability.

Performance Enhancements

The 3527047 Turbocharger Compressor Impeller can contribute to performance enhancements in heavy-duty trucks when properly tuned and optimized for specific applications. Adjustments to the turbocharger system, including the impeller, can lead to improvements in engine response, power output, and overall efficiency. Careful consideration of the engine’s requirements and operating conditions is necessary to achieve the best results.

Common Myths and Misconceptions

There are several misconceptions about turbocharger compressor impellers that can lead to misunderstandings about their function and maintenance. It is important to clarify these myths with accurate information to ensure proper understanding and use of these components. Educating users on the true capabilities and requirements of turbocharger compressor impellers can lead to better engine performance and longevity.

Cummins: A Brief Overview

Cummins Inc. is a well-established manufacturer in the automotive and heavy-duty truck industry, known for its commitment to innovation and quality. With a diverse product range that includes engines, turbochargers, and filtration systems, Cummins has built a reputation for reliability and performance. The company’s focus on advancing technology and meeting the needs of its customers underscores its position as a leader in the industry 2.

Turbocharger Compressor Impeller Compatibility with Cummins Engines

The Turbocharger Compressor Impeller part number 3527047, manufactured by Cummins, is designed to fit a range of Cummins engines. This part is integral to the turbocharger system, responsible for compressing the intake air before it enters the engine’s combustion chamber, thereby enhancing engine performance.

N14 CELECT and N14 CELECT PLUS Engines

The N14 CELECT and N14 CELECT PLUS engines are part of Cummins’ lineup of medium-duty diesel engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications such as trucks and construction equipment. The turbocharger compressor impeller part 3527047 is specifically engineered to fit these engines, ensuring optimal air compression and efficient engine operation.

N14 MECHANICAL Engine

The N14 MECHANICAL engine is another variant in the N14 series, distinguished by its mechanical fuel injection system. This engine is also utilized in heavy-duty applications, and the turbocharger compressor impeller part 3527047 is compatible with it. This compatibility ensures that the engine maintains its performance characteristics, providing the necessary air compression for efficient combustion.

NH/NT 855 Engine

The NH/NT 855 engine is a part of Cummins’ heavy-duty diesel engine series, designed for use in on-highway and vocational applications. The turbocharger compressor impeller part 3527047 is engineered to fit this engine, ensuring that it delivers the required air compression to meet the demands of these high-performance applications.

QSK19G and QSK38 CM850 MCRS Engines

The QSK19G and QSK38 CM850 MCRS engines are part of Cummins’ QSK series, known for their high power output and efficiency. These engines are used in a variety of applications, including power generation and marine. The turbocharger compressor impeller part 3527047 is designed to fit these engines, ensuring that they achieve the necessary air compression for optimal performance.

Role of Part 3527047 Turbocharger Compressor Impeller in Engine Systems

The Part 3527047 Turbocharger Compressor Impeller is an integral component within the turbocharger system, significantly enhancing the performance and efficiency of the engine. Its primary function is to compress the intake air before it enters the combustion chamber, thereby increasing the air density and allowing more fuel to be burned, which results in greater power output.

Integration with Key Engine Components

-

Aftermarket Turbocharger: When integrated into an aftermarket turbocharger, the impeller works in tandem with the turbine to drive the compressor wheel. This setup is often chosen for performance enhancements, where the impeller’s efficiency directly influences the overall boost pressure generated.

-

Cam Follower Housing and Camshaft: The increased air density provided by the impeller allows the camshaft, particularly the camshaft on the right bank, to operate more effectively. This is because the cam follower housing ensures precise valve timing, which is crucial for maximizing the benefits of the compressed air.

-

Connecting Rod and Piston: The enhanced air-fuel mixture resulting from the impeller’s compression leads to more forceful combustion events. This increased pressure is transmitted through the connecting rod to the piston, driving it downward with greater force and efficiency.

-

Cylinder Head: The compressed air delivered by the impeller ensures that the cylinder head receives a denser air-fuel mixture. This is particularly beneficial during high-RPM operations, where the cylinder head’s design can more effectively utilize the increased air density for better combustion.

-

Injector and Injector Plumbing: The impeller’s role in increasing air density necessitates a corresponding increase in fuel delivery. The injector and injector plumbing must be capable of delivering the precise amount of fuel to match the denser air, ensuring optimal combustion and performance.

-

Core Assembly and Heat Management: In systems utilizing core assemblies like Heat3B or Heat60, the impeller’s efficiency in compressing air is vital. These core assemblies are designed to manage the heat generated during compression, ensuring that the air remains at an optimal temperature for combustion. The Heat60 Turbocharger, in particular, benefits from the impeller’s ability to maintain consistent boost levels under varying thermal conditions.

-

Performance Parts and Turbocharger Kits: When incorporated into performance parts or turbocharger kits, the impeller is often a focal point for modifications. Engineers and mechanics may adjust the impeller’s design to achieve specific performance goals, such as higher boost pressures or improved throttle response.

-

Dataplate and EBM: Performance Parts: The dataplate on the turbocharger will often reflect the specifications of the impeller, including its material, design, and expected performance metrics. EBM performance parts, including turbochargers, are engineered to complement the impeller’s capabilities, ensuring that the entire system operates synergistically for maximum performance.

Conclusion

The Part 3527047 Turbocharger Compressor Impeller plays a significant role in enhancing the efficiency and performance of various engine components. Its ability to compress intake air effectively is a cornerstone of modern turbocharged engine systems, directly influencing the operation of critical components such as the camshaft, cylinder head, and injectors.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.