This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Compressor Impeller, specifically Part #3528123 by Cummins, is a vital component in heavy-duty truck engines. It is designed to enhance engine performance and efficiency. Cummins, a renowned manufacturer in the automotive industry, produces this part, leveraging their expertise in diesel engines and related components 1.

Basic Concepts of Turbocharger Compressor Impellers

Turbocharger compressor impellers operate on the principle of compressing intake air before it enters the engine’s combustion chamber. This compression increases the air density, allowing more oxygen to be available for combustion. As a result, the engine can burn more fuel efficiently, leading to improved power output and fuel economy. The impeller is a rotating component within the turbocharger that accelerates the airflow, creating the necessary pressure for efficient combustion 2.

Role of the 3528123 Turbocharger Compressor Impeller in Truck Operation

This Cummins part plays a significant role in enhancing engine performance and efficiency in commercial trucks. By compressing the intake air, it ensures that the engine receives a denser air-fuel mixture, which leads to more complete combustion. This results in increased power output and improved fuel efficiency, making it a valuable component for heavy-duty applications 3.

Key Features of the 3528123 Turbocharger Compressor Impeller

The 3528123 is distinguished by several key features. Its design is optimized for maximum airflow and efficiency, ensuring that the engine receives the necessary air pressure for optimal performance. The impeller is constructed from high-quality materials that can withstand the high temperatures and pressures within the turbocharger system. Additionally, it incorporates technological advancements that enhance its durability and performance.

Benefits of Using the 3528123 Turbocharger Compressor Impeller

Incorporating this part into truck engines offers several advantages. It contributes to improved power output, allowing the engine to deliver more torque and horsepower. Additionally, it enhances fuel efficiency by ensuring more complete combustion, which can lead to cost savings over time. The impeller’s robust construction and advanced design also contribute to increased reliability and longevity.

Installation and Integration

Proper installation and integration of the 3528123 within truck engine systems are crucial for optimal performance. It is important to ensure that the impeller is compatible with the specific engine model and that it is correctly fitted within the turbocharger housing. Following manufacturer guidelines and recommendations during installation will help achieve the best results 4.

Performance Enhancements

This Turbocharger Compressor Impeller contributes to overall engine performance in several ways. By increasing the density of the intake air, it allows the engine to produce more power and torque. This results in improved acceleration and responsiveness, making the truck more capable in various driving conditions. Additionally, the enhanced airflow leads to better fuel efficiency, reducing operating costs.

Maintenance and Troubleshooting

Routine maintenance practices are essential to ensure the optimal performance and longevity of the 3528123. Regular inspections for signs of wear or damage, such as cracks or erosion, are recommended. Cleaning the impeller to remove any buildup of dirt or debris will help maintain its efficiency. Troubleshooting techniques, such as checking for proper fitment and ensuring there are no obstructions in the airflow, can help identify and resolve issues promptly.

Common Issues and Solutions

Common issues that may arise with the 3528123 include wear and tear due to high-speed rotation and exposure to high temperatures. Preventive measures such as regular maintenance and inspections can help mitigate these issues. If problems are detected, such as reduced performance or unusual noises, it may be necessary to replace the impeller to restore optimal engine function.

Cummins: Manufacturer Overview

Cummins is a leading manufacturer of diesel engines and related components, known for their reputation for quality and innovation in the automotive industry. With a strong focus on research and development, Cummins continually strives to improve the performance and efficiency of their products. Their commitment to excellence has made them a trusted name in the production of turbocharger components, including the 3528123.

Turbocharger Compressor Impeller for Cummins Engines

The turbocharger compressor impeller, part number 3528123, is a critical component in the Cummins L10 and M11 CELECT engines. This part is integral to the engine’s performance, ensuring efficient air intake and compression.

In the Cummins L10 CELECT engine, the turbocharger compressor impeller works in tandem with the turbocharger to enhance the engine’s power output. The impeller draws in air, compresses it, and then directs it into the combustion chamber, facilitating a more efficient burn of fuel. This process is essential for maintaining optimal engine performance and efficiency.

Similarly, in the Cummins M11 CELECT engine, the turbocharger compressor impeller plays a pivotal role. It ensures that the engine receives a consistent and adequate supply of compressed air, which is crucial for the engine’s overall performance and longevity. The design and precision of this component are critical to achieving the desired balance between power and efficiency in both engines.

The turbocharger compressor impeller is engineered to withstand the high-stress environment within the engine, ensuring durability and reliability over extended periods of operation. Its compatibility with both the L10 and M11 CELECT engines underscores its versatility and importance in maintaining engine performance.

Understanding the Role of Part 3528123 in Engine Systems

The 3528123 is a key component in the functionality of various engine systems, particularly in enhancing performance and efficiency. This impeller is integral to the operation of the turbocharger, which is designed to increase an internal combustion engine’s efficiency and power output by forcing extra air into the combustion chamber.

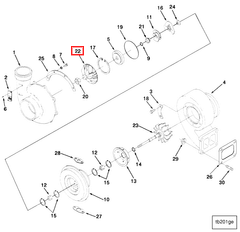

Integration with Core Assembly and Turbocharger Core

When installed within the core assembly or H2E turbocharger core, the impeller works in concert with other components to optimize air intake. The impeller’s design allows it to spin at high speeds, compressing the intake air before it enters the engine. This compressed air mixes with fuel more efficiently, leading to a more powerful combustion process.

Contribution to Emissions Rebuild Kit

In the context of an emissions rebuild kit, the impeller plays a significant role in reducing harmful emissions. By improving the air-fuel mixture, the engine burns fuel more completely, which reduces the amount of unburned hydrocarbons and other pollutants released into the atmosphere. This is particularly important in meeting stringent environmental regulations and standards.

Enhancing Performance in Turbocharger Kits

Within a turbocharger kit, the impeller is a fundamental part that directly influences the engine’s performance. The kit typically includes various components designed to work together to boost engine power. The impeller’s efficiency in compressing air is a determining factor in how much additional power the turbocharger can provide.

Role in H2E Turbocharger Core

Specifically, in an H2E turbocharger core, the impeller is engineered to handle the unique demands of high-efficiency, high-emission turbochargers. The H2E (High Efficiency) designation indicates a focus on both performance and environmental impact, where the impeller’s role is to balance these two aspects effectively.

Impact on Overall Engine Performance

The performance of the engine is significantly impacted by the efficiency of the impeller. In high-performance engines, the impeller must be able to withstand extreme conditions and maintain its structural integrity and efficiency. This ensures that the engine can deliver consistent power output under various driving conditions.

Conclusion

In summary, the 3528123 Turbocharger Compressor Impeller is a vital component in enhancing engine performance, efficiency, and emissions control across various engine systems and configurations. Its role in compressing intake air is fundamental to the operation of turbochargers and is a key factor in the overall performance and environmental impact of the engine.

-

Hilgers, Michael. Entire Vehicle: Second Edition. Springer Nature, 2023.

↩ -

Xin, Qianfan. Diesel Engine System Design. Woodhead Publishing, 2011.

↩ -

Khajepour, Amir. Synthesis Lectures on Advances in Automotive Technology. Springer, 2023.

↩ -

Cummins Inc. Operation and Maintenance Manual. Bulletin Number 6378610, AFT CM1881 AS104.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.