3635887

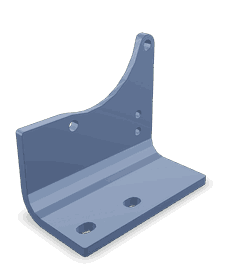

Turbocharger Bracket

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Turbocharger Bracket 3635887, manufactured by Cummins, is a critical component in the automotive and heavy-duty truck industry. This part supports the turbocharger, which is essential for the engine’s performance. Understanding its purpose, features, and proper installation is important for maintaining optimal engine operation.

Basic Concepts of Turbocharger Brackets

A turbocharger bracket serves as the mounting point for the turbocharger within an engine system. It secures the turbocharger to the engine, allowing it to operate efficiently. The bracket’s design and material are crucial for withstanding the high temperatures and pressures generated by the turbocharger. By providing a stable platform, the bracket contributes to the overall performance and reliability of the engine 1.

Purpose of Turbocharger Bracket 3635887

The 3635887 Turbocharger Bracket is designed to support the turbocharger in heavy-duty truck engines. It ensures the turbocharger is securely mounted, allowing it to function effectively within the engine system. This bracket interacts with various components of the turbocharger system, including the turbocharger itself, the exhaust manifold, and the engine block, to maintain stability and alignment 2.

Key Features

This Cummins part is constructed from high-quality materials, ensuring durability and resistance to the extreme conditions within an engine. Its design includes precise mounting points and robust construction to handle the stresses induced by the turbocharger’s operation. Additionally, the bracket may feature heat shielding or insulation to protect surrounding components from the turbocharger’s high temperatures 3.

Benefits

Installing the 3635887 Turbocharger Bracket can lead to several advantages. It enhances the stability of the turbocharger, which in turn improves engine efficiency. A securely mounted turbocharger operates more reliably, potentially increasing power output and fuel economy. The bracket’s design also contributes to the longevity of the turbocharger and other engine components by reducing wear and stress 4.

Installation Process

Proper installation of the 3635887 Turbocharger Bracket is crucial for ensuring optimal performance and longevity. The process involves securing the bracket to the engine block using the provided mounting hardware. It is important to follow the manufacturer’s guidelines for torque specifications and alignment to ensure the turbocharger is properly positioned. Careful attention to detail during installation will help prevent issues such as turbocharger misalignment or instability 5.

Troubleshooting and Maintenance

Common issues with turbocharger brackets include loosening over time, which can lead to turbocharger instability. Regular inspections for signs of wear, corrosion, or damage are recommended to identify potential problems early. Maintenance practices such as tightening mounting bolts to the specified torque and applying anti-seize compound where appropriate can help prolong the life of the bracket and ensure continued reliable operation 6.

Compatibility and Application

The 3635887 Turbocharger Bracket is designed for use in specific Cummins engines found in heavy-duty trucks. Its application is tailored to meet the demands of these engines, ensuring compatibility and optimal performance. Users should consult the manufacturer’s guidelines for detailed information on compatibility with specific engine models and truck applications 7.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the automotive and heavy-duty truck industry. The company’s extensive product range includes engines, turbochargers, and related components, all designed to meet the rigorous demands of commercial and industrial applications 8.

Turbocharger Bracket 3635887 Compatibility with Cummins Engines

The turbocharger bracket 3635887 is designed to fit seamlessly with a range of Cummins engines. This part is essential for the proper installation and operation of the turbocharger, ensuring efficient airflow and optimal engine performance.

K50 Series

The K50 series engines are robust and versatile, commonly used in various industrial and marine applications. The turbocharger bracket 3635887 is engineered to fit these engines, providing the necessary support and alignment for the turbocharger. This ensures that the turbocharger operates within the specified parameters, enhancing the engine’s efficiency and longevity.

QSK50 CM2150 and QSK50 CM2350

The QSK50 CM2150 and QSK50 CM2350 engines are part of Cummins’ QSK series, known for their high power output and reliability. The turbocharger bracket 3635887 is specifically designed to fit these models, ensuring that the turbocharger is securely mounted and properly aligned. This is crucial for maintaining the engine’s performance and preventing any potential damage due to misalignment.

MCRS and K108

The MCRS and K108 engines are also compatible with the turbocharger bracket 3635887. This bracket is designed to fit these engines, providing the necessary support and alignment for the turbocharger. This ensures that the turbocharger operates within the specified parameters, enhancing the engine’s efficiency and longevity.

Understanding the Integration of Part 3635887 Turbocharger Bracket in Engine Systems

The Part 3635887 Turbocharger Bracket is a critical component in the arrangement of various engine systems, facilitating the secure mounting of the turbocharger to the engine block. This bracket ensures that the turbocharger is held in the correct position, allowing for optimal performance and efficiency of the engine.

Role in Turbocharger Arrangement

The primary function of the Turbocharger Bracket is to provide a stable and secure mounting point for the turbocharger. This is vital for maintaining the turbocharger’s alignment with other critical components such as the air inlet connection. Proper alignment ensures that the airflow into the turbocharger is smooth and uninterrupted, which is fundamental for the turbocharger’s performance.

Interaction with Performance Parts

In high-performance engine setups, the Turbocharger Bracket plays a significant role in integrating various performance parts. It must be compatible with upgraded turbochargers and other performance-enhancing components to ensure that the entire system works in harmony. The bracket’s design often needs to accommodate larger or more complex turbochargers, which are common in performance applications.

Ensuring Turbocharger Connection Integrity

The integrity of the turbochargers connection to the engine is heavily reliant on the Turbocharger Bracket. It must withstand the high temperatures and pressures generated by the turbocharger, ensuring that the connection remains secure under all operating conditions. This is particularly important in racing or high-stress environments where engine performance is pushed to its limits.

Contribution to Overall Engine Performance

By securely mounting the turbocharger, the Turbocharger Bracket indirectly contributes to the overall performance of the engine. A well-mounted turbocharger can operate more efficiently, providing better airflow and thus enhancing engine power and responsiveness. This is especially noticeable in turbocharged engines where the turbocharger plays a significant role in power delivery.

Conclusion

The Part 3635887 Turbocharger Bracket is a key component in the successful integration and operation of turbochargers within engine systems. Its role in maintaining the proper arrangement and connection of the turbocharger ensures that the engine can perform at its best, whether in standard or high-performance applications.

-

Crolla, D. (2015). Crolla Encyclopedia. Wiley.

↩ -

Huzij, R., Spano, A., & Bennett, S. (2019). Modern Diesel Technology: Heavy Equipment Systems. Cengage Learning.

↩ -

Reif, K. (2014). Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems. Springer Vieweg.

↩ -

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩ -

Cummins Inc. (n.d.). Master Repair Manual. Bulletin Number 5660086.

↩ -

Cummins Inc. (n.d.). Master Repair Manual. Bulletin Number 5660086.

↩ -

Cummins Inc. (n.d.). Master Repair Manual. Bulletin Number 5660086.

↩ -

Cummins Inc. (n.d.). Master Repair Manual. Bulletin Number 5660086.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.