3782559

Variable Geometry Turbocharger Speed Sensor Kit

Cummins®

DISCONTINUED

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Variable Geometry Turbocharger Speed Sensor Kit by Cummins is designed to enhance the performance and efficiency of heavy-duty trucks. This kit is integral to the operation of the engine, providing precise monitoring and adjustment of turbocharger speed to optimize engine performance 1.

Basic Concepts

Turbochargers work by compressing the air entering the engine, which allows for more fuel to be burned and thus increases power output. Variable Geometry Turbochargers (VGT) take this a step further by adjusting the angle of the turbine vanes to control the flow of exhaust gases. This adjustment allows for more precise control over the turbocharger’s speed and, consequently, the engine’s performance. The speed sensor kit integrates with these systems by providing real-time data on turbocharger speed, enabling the engine control unit (ECU) to make necessary adjustments 2.

Functionality of the Variable Geometry Turbocharger Speed Sensor Kit

This part operates by monitoring the rotational speed of the turbocharger. This data is crucial for the ECU to make informed decisions about fuel injection and air intake. By continuously providing accurate speed readings, the sensor kit allows the ECU to adjust the VGT vanes for optimal performance under varying driving conditions 3.

Key Features

The Variable Geometry Turbocharger Speed Sensor Kit is characterized by several key features. These include high sensor accuracy, ensuring precise measurements of turbocharger speed; durability, designed to withstand the harsh conditions of heavy-duty truck engines; and seamless integration capabilities with various engine control units (ECUs), allowing for easy installation and operation.

Benefits

Utilizing this Cummins part offers several advantages. It contributes to improved engine performance by ensuring the turbocharger operates at optimal speeds. This results in enhanced fuel efficiency, as the engine can burn fuel more effectively. Additionally, the kit aids in reducing emissions by allowing for more precise control over the combustion process.

Installation and Compatibility

Proper installation of the Variable Geometry Turbocharger Speed Sensor Kit is vital for its effective operation. It is designed to be compatible with a range of Cummins engine models, ensuring a broad application across different heavy-duty truck fleets. Following manufacturer guidelines during installation is recommended to ensure optimal performance and integration with the engine system.

Maintenance and Troubleshooting

Regular maintenance of the Variable Geometry Turbocharger Speed Sensor Kit is important to ensure its longevity and optimal performance. This includes checking for any signs of wear or damage to the sensor and ensuring it remains securely connected to the ECU. Common troubleshooting tips involve verifying the sensor’s connection and ensuring the ECU is receiving accurate data. If issues arise, consulting the manufacturer’s guidelines or a professional technician is advised.

Impact on Engine Performance

The Variable Geometry Turbocharger Speed Sensor Kit plays a significant role in enhancing overall engine performance. By providing accurate turbocharger speed data, it allows for better management of torque output, power delivery, and engine responsiveness. This results in a more efficient and powerful engine, capable of meeting the demands of heavy-duty applications.

Regulatory Compliance

The use of the Variable Geometry Turbocharger Speed Sensor Kit assists trucks in meeting emissions regulations and standards. By enabling more precise control over the combustion process, it helps reduce harmful emissions, ensuring compliance with environmental regulations.

Cummins Overview

Cummins Inc. is a leader in the automotive and heavy-duty truck industry, known for its commitment to innovation and quality in engine technology. With a rich history of developing advanced engine solutions, Cummins continues to push the boundaries of what is possible in engine performance and efficiency. The Variable Geometry Turbocharger Speed Sensor Kit is a testament to Cummins’ dedication to enhancing the capabilities of heavy-duty trucks through technological advancement.

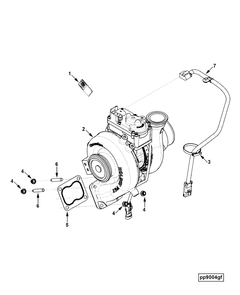

Components of the Cummins 3782559 Variable Geometry Turbocharger Speed Sensor Kit

Hexagon Flange Head Cap Screw (3527184)

The Hexagon Flange Head Cap Screw is a critical fastening component within the 3782559. Its primary role is to securely attach the turbocharger speed sensor to the turbocharger housing. The flange head design provides additional surface area for better grip and distribution of clamping force, ensuring a stable and vibration-resistant connection. This is essential for maintaining the integrity of the sensor’s readings and the overall performance of the turbocharger system.

Turbocharger Speed Sensor (4307345)

The Turbocharger Speed Sensor is the core component of the kit, responsible for monitoring the rotational speed of the turbocharger. Accurate speed data is crucial for the engine control unit (ECU) to optimize fuel injection and timing, enhancing engine performance and efficiency. The sensor is designed to withstand the high temperatures and pressures within the turbocharger environment, ensuring reliable operation over the lifespan of the engine.

Wire Retaining Clip (4307444)

The Wire Retaining Clip plays a supportive yet vital role in the kit by securing the wiring harness that connects the turbocharger speed sensor to the ECU. This clip ensures that the wiring remains neatly organized and protected from potential damage due to engine vibrations or heat. Proper wire management is essential for maintaining signal integrity and preventing electrical issues that could lead to sensor malfunction or inaccurate readings.

Conclusion

The Variable Geometry Turbocharger Speed Sensor Kit by Cummins is a sophisticated component designed to optimize the performance and efficiency of heavy-duty truck engines. Through precise monitoring and adjustment of turbocharger speed, this part ensures enhanced engine performance, improved fuel efficiency, and reduced emissions. Its compatibility with various Cummins engine models, coupled with its durable construction and seamless integration capabilities, makes it a valuable asset for heavy-duty truck fleets. Regular maintenance and proper installation are key to maximizing the benefits of this part, ensuring it continues to deliver optimal performance and compliance with regulatory standards.

-

SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety, R. Matthew Brach, SAE International, 2023.

↩ -

Transmissions and Drivetrain Design, Michael Hilgers, Springer Vieweg, 2022.

↩ -

Motor Vehicle Mechanics Textbook, Fifth Edition, F. K. Sully, Heinemann Professional Publishing, 1998.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.