This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3918587 Turbocharger Oil Drain Tube is a component designed to facilitate the drainage of oil from the turbocharger in heavy-duty trucks. Its role is significant in maintaining the efficiency and reliability of the turbocharger, which in turn contributes to the overall performance of the truck’s engine.

Basic Concepts of Turbocharger Oil Drain Tubes

Turbocharger systems utilize exhaust gases to drive a turbine, which compresses intake air and increases engine power. Oil is circulated within the turbocharger to lubricate moving parts and maintain optimal temperature. The oil drain tube plays a role in the turbocharger system by allowing excess oil to be returned to the engine’s lubrication system, thus contributing to the overall efficiency and reliability of the turbocharger 1.

Purpose of the Cummins 3918587 Turbocharger Oil Drain Tube

The Cummins 3918587 Turbocharger Oil Drain Tube is designed to facilitate the drainage of oil from the turbocharger. By ensuring that excess oil is efficiently returned to the engine’s lubrication system, it helps maintain optimal turbocharger performance and longevity. This process is vital for preventing oil buildup, which can lead to decreased efficiency and potential damage to the turbocharger.

Key Features

The Cummins 3918587 Turbocharger Oil Drain Tube is constructed from durable materials to withstand the high temperatures and pressures within the turbocharger system. Its design includes precise fittings to ensure a secure connection and efficient oil drainage. Unique attributes such as reinforced sections and corrosion-resistant coatings enhance its functionality and durability.

Benefits

Using the Cummins 3918587 Turbocharger Oil Drain Tube offers several benefits. It contributes to improved engine performance by ensuring that the turbocharger operates within optimal parameters. Enhanced turbocharger longevity is achieved through efficient oil management, reducing the risk of wear and damage. Additionally, the drain tube helps minimize maintenance requirements by preventing oil buildup and associated issues.

Troubleshooting and Maintenance

Common issues with turbocharger oil drain tubes include blockages, leaks, and wear. Regular inspection for signs of damage or corrosion is recommended to ensure the tube’s efficient operation. Maintenance practices such as cleaning the tube and ensuring secure fittings can help prolong its lifespan. Replacement schedules should be followed based on manufacturer recommendations or when signs of wear are detected.

Installation Considerations

Installing the Cummins 3918587 Turbocharger Oil Drain Tube requires attention to detail to ensure a proper and secure fit. It is important to follow the manufacturer’s guidelines for installation, including torque specifications for fittings and ensuring that all connections are tight and free from obstructions. Proper installation contributes to the efficient operation of the turbocharger and the overall engine system.

Common Failure Modes

Turbocharger oil drain tubes can fail due to wear, leakage, or blockages. Wear can occur from prolonged exposure to high temperatures and pressures, while leakage may result from corroded or damaged fittings. Blockages can happen due to debris or sludge buildup within the tube. These failures can impact engine performance by disrupting the oil drainage process, leading to potential turbocharger damage.

Impact on Engine Performance

The proper functioning of the Turbocharger Oil Drain Tube influences engine performance, fuel efficiency, and emissions. Efficient oil drainage ensures that the turbocharger operates within optimal parameters, contributing to smooth engine operation and reduced wear. Conversely, a malfunctioning drain tube can lead to oil buildup, decreased efficiency, and potential turbocharger failure, impacting overall engine performance and fuel economy 2.

About Cummins

Cummins Inc. is a leading manufacturer in the automotive and heavy-duty truck industries, known for its commitment to quality and innovation in engine component manufacturing. With a rich history and a diverse product range, Cummins has established a reputation for producing reliable and high-performance engine components. The company’s dedication to excellence is evident in its continuous pursuit of technological advancements and customer satisfaction.

Compatibility with Cummins Engines

The Turbocharger Oil Drain Tube, part number 3918587, is compatible with several Cummins engine models, including the 6B5.9 and G5.9. These engines are known for their robust performance and reliability, often used in heavy-duty applications.

-

6B5.9 Engine: This engine variant benefits from the precise engineering of the Turbocharger Oil Drain Tube, which helps maintain optimal oil levels within the turbocharger, preventing both over-lubrication and insufficient lubrication. This balance is crucial for the longevity and performance of the turbocharger.

-

G5.9 Engine: Similarly, the G5.9 engine relies on the Turbocharger Oil Drain Tube to ensure that the turbocharger is adequately lubricated. This part’s design allows for the efficient removal of excess oil, which can otherwise lead to oil contamination and potential damage to the turbocharger.

By ensuring that the turbocharger operates within its designed parameters, the Turbocharger Oil Drain Tube contributes to the overall reliability and efficiency of these Cummins engines.

Role of Part 3918587 Turbocharger Oil Drain Tube in Engine Systems

The Turbocharger Oil Drain Tube, part number 3918587, is an essential component in the turbocharger plumbing system of an engine. It is designed to facilitate the efficient drainage of oil from the turbocharger, ensuring that the system operates smoothly and effectively.

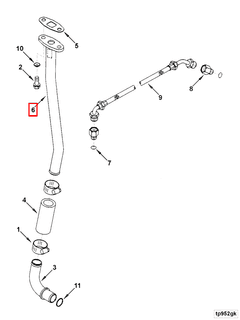

Integration with Turbocharger Plumbing

In the turbocharger plumbing system, the Turbocharger Oil Drain Tube is strategically positioned to connect the turbocharger to the engine’s oil return system. This connection allows for the continuous circulation of oil, which is vital for lubricating the turbocharger’s moving parts, such as the turbine and compressor wheels.

Function in Oil Management

The primary function of the Turbocharger Oil Drain Tube is to provide a reliable pathway for oil to drain back into the engine’s oil sump after lubricating the turbocharger. This ensures that the oil is continuously recirculated, maintaining optimal lubrication and cooling for the turbocharger.

Interaction with Other Components

- Turbocharger Bearings: The oil drained through the Turbocharger Oil Drain Tube has previously lubricated the turbocharger’s bearings, reducing friction and wear.

- Oil Return Lines: The tube connects to the engine’s oil return lines, ensuring that the used oil is efficiently returned to the sump for filtration and re-use.

- Oil Sump: The drained oil accumulates in the oil sump, where it is filtered and recirculated to maintain a consistent supply of clean oil to the turbocharger and other engine components.

Importance in System Maintenance

Regular maintenance of the Turbocharger Oil Drain Tube is important to prevent oil leaks and ensure the turbocharger operates within specified parameters. A well-maintained drain tube contributes to the overall efficiency and longevity of the turbocharger and the engine system 3.

Conclusion

The Cummins 3918587 Turbocharger Oil Drain Tube plays a vital role in maintaining the efficiency and reliability of the turbocharger in heavy-duty trucks. By facilitating the drainage of oil, it ensures optimal turbocharger performance and longevity, contributing to the overall engine performance. Regular maintenance and proper installation are crucial for the efficient operation of this part.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.