This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Electric Actuator Kit (Part #4034211) by Cummins is designed to enhance the performance of turbochargers in commercial trucks. This part plays a role in the efficient operation of these vehicles by optimizing turbocharger performance, which in turn improves engine efficiency and overall truck performance.

Basic Concepts

To understand this Cummins part, it is important to grasp the fundamental concepts of turbochargers and electric actuators. A turbocharger compresses the air entering the engine, allowing more air to be mixed with fuel, which results in more powerful combustion and increased engine power 1. An electric actuator controls the position of the turbocharger’s wastegate, which regulates the amount of exhaust gas bypassing the turbine. Together, these components work to enhance engine performance by ensuring the turbocharger operates within optimal parameters.

Purpose and Role

The Turbocharger Electric Actuator Kit serves to optimize the performance of the turbocharger in a truck’s engine. By precisely controlling the wastegate, the kit ensures that the turbocharger operates efficiently across a range of engine speeds and loads. This optimization leads to improved engine efficiency, increased power output, and better overall performance of the truck.

Key Features

The Turbocharger Electric Actuator Kit boasts several key features that contribute to its effectiveness. These include precision engineering, which ensures accurate control of the wastegate; durability, designed to withstand the harsh conditions of commercial truck operation; and compatibility with Cummins engines, guaranteeing seamless integration and performance.

Benefits

Installing the Turbocharger Electric Actuator Kit offers several benefits. These include increased engine power due to optimized turbocharger performance, improved fuel efficiency as a result of more efficient air-fuel mixture, and enhanced drivability, providing a smoother and more responsive driving experience.

Installation Process

Installing the Turbocharger Electric Actuator Kit involves several steps to ensure proper integration and function. Begin by disconnecting the battery to prevent any electrical issues. Next, remove the old actuator and wastegate assembly, taking care to note the position and orientation for reassembly. Install the new actuator, ensuring all connections are secure and properly aligned. Reconnect the battery and test the system to confirm proper operation. It is important to follow manufacturer guidelines and best practices throughout the installation process to ensure optimal performance.

Troubleshooting and Maintenance

Common issues with the Turbocharger Electric Actuator Kit may include actuator malfunctions or wastegate positioning errors. Troubleshooting these issues involves checking electrical connections, ensuring the actuator is receiving proper voltage, and verifying the wastegate moves freely without obstruction. Regular maintenance, such as inspecting connections and ensuring the actuator and wastegate are clean and free of debris, can help prevent issues and ensure long-term performance.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a strong reputation in the commercial truck industry for producing reliable, high-performance engines and components 2. The company’s commitment to innovation and quality ensures that its products, like the Turbocharger Electric Actuator Kit, meet the demanding requirements of commercial truck operators.

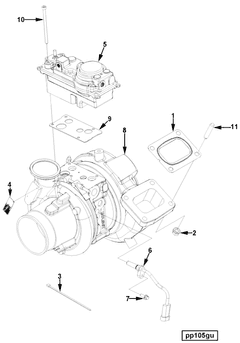

Components of the 4034211 Turbocharger Electric Actuator Kit

Electric Actuator

The electric actuator is the primary component of the kit. It is responsible for controlling the turbocharger’s variable geometry, adjusting the vanes to optimize airflow and boost pressure. This results in improved engine performance and efficiency 3.

Mounting Bracket

The mounting bracket secures the electric actuator to the turbocharger. It ensures a stable and precise fit, allowing the actuator to operate effectively and withstand the rigors of engine operation.

Wiring Harness

The wiring harness connects the electric actuator to the vehicle’s electrical system. It provides the necessary power and signals for the actuator to function, ensuring seamless integration with the engine’s control unit.

Connectors

Connectors are used to link the wiring harness to the actuator and the vehicle’s electrical system. They ensure a secure and reliable connection, preventing issues such as electrical shorts or signal loss.

Seals and Gaskets

Seals and gaskets are included to prevent leaks and ensure a tight fit between the actuator and the turbocharger. They play a role in maintaining the integrity of the system, preventing air or fluid leaks that could affect performance.

Calibration Tool

The calibration tool is used to fine-tune the electric actuator’s settings. It ensures that the actuator operates within the specified parameters, optimizing turbocharger performance and ensuring consistent engine output.

Instructions

Detailed instructions are provided to guide the installation and calibration process. They offer step-by-step guidance to ensure proper setup and operation, minimizing the risk of errors during installation.

Additional Fasteners

Additional fasteners, such as bolts and screws, are included to secure various components in place. They ensure that all parts of the kit are firmly attached, contributing to the overall stability and reliability of the system.

Conclusion

The Turbocharger Electric Actuator Kit (Part #4034211) by Cummins is a comprehensive solution for enhancing turbocharger performance in commercial trucks. By optimizing turbocharger operation, this part contributes to improved engine efficiency, increased power output, and enhanced drivability. Proper installation, regular maintenance, and understanding of the kit’s components are essential for maximizing its benefits and ensuring long-term performance.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.