This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

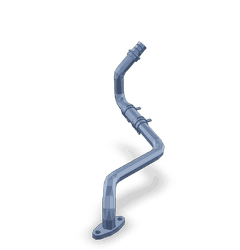

The Turbocharger Oil Drain Connection, identified by part number 5285973, is a component manufactured by Cummins, a renowned name in the automotive industry. This part is integral to the operation of heavy-duty truck engines, specifically within the turbocharger system. The Turbocharger Oil Drain Connection facilitates the efficient removal of oil from the turbocharger, which is vital for maintaining engine performance and longevity.

Basic Concepts of Turbocharger Oil Drain Connection

Turbochargers are devices that increase an engine’s power output by forcing extra air into the combustion chamber. This process, known as forced induction, allows more fuel to be burned, resulting in increased power. Within the turbocharger system, the oil drain connection plays a role by allowing the removal of oil that has lubricated the turbocharger’s moving parts. This oil, if not drained, can accumulate and potentially lead to decreased efficiency and performance of the turbocharger 1.

Purpose of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection serves to maintain the efficiency of the turbocharger by enabling the removal of oil. This function is crucial as it prevents oil buildup, which can hinder the turbocharger’s operation. By ensuring that oil is efficiently drained, the connection helps in preserving the turbocharger’s performance and extending its operational life 2.

Key Features of Part #5285973

Part #5285973 is designed with specific features that enhance its functionality. Constructed from durable materials, this Turbocharger Oil Drain Connection is built to withstand the high pressures and temperatures within the turbocharger system. Its design includes precise connection types that ensure a secure fit, minimizing the risk of leaks and ensuring efficient oil drainage.

Benefits of Using the Turbocharger Oil Drain Connection

The use of the Turbocharger Oil Drain Connection offers several advantages. It contributes to improved engine performance by ensuring that the turbocharger operates efficiently. Additionally, it reduces maintenance requirements by preventing oil buildup, which can lead to turbocharger failures. Furthermore, it enhances the reliability of the turbocharger, leading to a more consistent engine performance over time 3.

Installation and Compatibility

Proper installation of the Turbocharger Oil Drain Connection is key to its effective operation. It is designed to be compatible with various Cummins engine models and other relevant turbocharger systems. Following manufacturer guidelines during installation ensures that the connection functions as intended, contributing to the overall efficiency of the engine.

Troubleshooting Common Issues

Common issues with Turbocharger Oil Drain Connections may include oil leaks, connection failures, and performance declines. Troubleshooting these problems involves inspecting the connection for signs of wear or damage, ensuring it is properly installed, and checking for any obstructions in the oil drainage path. Addressing these issues promptly can help maintain the turbocharger’s efficiency and prevent more significant engine problems.

Maintenance Tips

Regular maintenance of the Turbocharger Oil Drain Connection is important for its longevity and efficiency. This includes periodic inspections for signs of wear or damage, cleaning the connection to remove any debris, and ensuring that it remains securely fitted. Adhering to these maintenance practices can help prevent issues and ensure the turbocharger operates at optimal efficiency.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history of innovation and quality, Cummins has established a strong reputation in the automotive industry. The company’s commitment to quality is evident in its wide range of engine components, including the Turbocharger Oil Drain Connection, which is designed to meet the demanding requirements of heavy-duty applications.

Turbocharger Oil Drain Connection in Cummins Engines

The turbocharger oil drain connection, part number 5285973, is a critical component in the lubrication system of certain Cummins engines. This part ensures that oil is properly drained from the turbocharger, maintaining optimal engine performance and longevity.

B6.7 CM2350

In the B6.7 CM2350 engine, the turbocharger oil drain connection is integral to the engine’s lubrication system. It facilitates the removal of oil from the turbocharger, preventing oil buildup that could lead to excessive pressure and potential damage. This part is designed to work seamlessly with the engine’s architecture, ensuring efficient oil flow and maintaining the turbocharger’s operational integrity.

B135B

Similarly, in the B135B engine, the turbocharger oil drain connection plays a vital role. It ensures that the turbocharger is adequately lubricated while also allowing for the efficient removal of excess oil. This balance is crucial for maintaining the turbocharger’s performance and preventing oil-related issues that could compromise engine efficiency.

Grouping of Engines

Both the B6.7 CM2350 and B135B engines benefit from the turbocharger oil drain connection in similar ways. The part’s design is optimized to fit these engines, ensuring that oil is effectively managed within the turbocharger system. This commonality allows for easier maintenance and repair, as the same part can be used across different engine models, streamlining the process for technicians and operators.

Role of Part 5285973 Turbocharger Oil Drain Connection in Engine Systems

The part 5285973 Turbocharger Oil Drain Connection is an essential component in the maintenance and operation of engine systems that incorporate turbochargers. Its primary function is to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters.

Integration with Turbocharger Systems

In turbocharged engines, the turbocharger oil drain connection is integrated into the lubrication circuit of the turbocharger. This connection allows for the periodic removal of oil that has been used to lubricate the turbocharger’s bearings and other moving parts. The drained oil is typically returned to the engine’s oil sump, where it can be re-circulated after filtration. This process helps maintain the quality of the oil and ensures that the turbocharger continues to receive clean, properly lubricated oil.

Interaction with Plumbing Systems

The turbocharger oil drain connection also interacts with the engine’s plumbing system. It is connected to oil lines that transport oil from the turbocharger to the oil sump. These lines are part of the engine’s overall oil circulation system, which includes the oil pump, filter, and various passages within the engine block and head. The efficient design of these oil lines ensures that oil is delivered under pressure to the turbocharger and returned effectively after use.

Maintenance and Operational Benefits

By incorporating the turbocharger oil drain connection into the engine system, mechanics and engineers can more easily perform maintenance tasks such as oil changes and inspections. Regular drainage of oil from the turbocharger helps prevent the buildup of contaminants and degradation of oil quality, which can lead to increased turbocharger efficiency and longevity. Additionally, this component allows for the monitoring of oil condition, providing valuable insights into the health of the turbocharger and the overall engine system.

Conclusion

The Turbocharger Oil Drain Connection, part number 5285973, plays a significant role in the lubrication and maintenance of turbocharged engine systems. Its integration with the turbocharger and plumbing systems ensures efficient oil circulation and facilitates essential maintenance procedures. Regular maintenance and proper installation of this Cummins part are crucial for maintaining engine performance and longevity.

-

Hilgers, Michael. Electrical Systems and Mechatronics, Second Edition. Springer Vieweg, 2023.

↩ -

Khajepour, Amir. Synthesis Lectures on Advances in Automotive Technology. Springer, 2023.

↩ -

Van Gelder, Kirk T. Fundamentals of Automotive Technology Principles and Practice. Jones Bartlett Learning, 2018.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.