This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

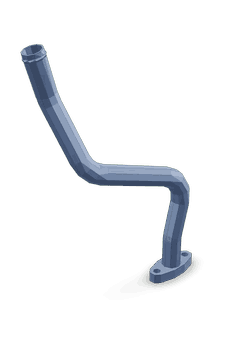

The Cummins 5289821 Turbocharger Oil Drain Connection is designed to facilitate the drainage of oil from the turbocharger in heavy-duty trucks. This component ensures that excess oil does not accumulate within the turbocharger, which could lead to performance issues and potential damage. It plays a role in maintaining the efficiency and reliability of the truck’s engine 1.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger oil drain connections allow used oil to exit the turbocharger system. This process is vital for the turbocharger’s health, as it prevents oil buildup that can lead to contamination and reduced efficiency. The drain connection is typically located at the lowest point of the turbocharger, ensuring that oil can flow out under the force of gravity 2.

Purpose and Role in Truck Operation

The Cummins 5289821 Turbocharger Oil Drain Connection maintains the turbocharger’s operational integrity by allowing for the regular removal of oil. This drainage is important for preventing oil buildup, which can hinder the turbocharger’s ability to compress air effectively. By ensuring smooth turbocharger operation, this component contributes to the overall efficiency and performance of the truck’s engine 3.

Key Features

The Cummins 5289821 Turbocharger Oil Drain Connection is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the high pressures and temperatures associated with turbocharger operation. The connection features a secure fitting mechanism to ensure a tight seal, preventing oil leaks and maintaining system integrity.

Benefits

Utilizing the Cummins 5289821 Turbocharger Oil Drain Connection offers several advantages. It contributes to improved turbocharger longevity by facilitating regular oil drainage, which helps to keep the turbocharger clean and operating efficiently. Additionally, it enhances engine performance by ensuring that the turbocharger functions optimally. Reduced maintenance requirements are another benefit, as the efficient drainage of oil minimizes the need for frequent inspections and cleanings.

Installation Process

Installing the Cummins 5289821 Turbocharger Oil Drain Connection involves several steps to ensure a secure and effective setup. Begin by ensuring the turbocharger is clean and free of any debris. Position the drain connection at the designated location on the turbocharger, aligning it with the oil passage. Use the appropriate tools to tighten the connection securely, taking care not to over-tighten, which could damage the fitting. Finally, perform a visual inspection to confirm that the connection is properly installed and sealed.

Maintenance Tips

To ensure the optimal performance and longevity of the Cummins 5289821 Turbocharger Oil Drain Connection, regular maintenance is recommended. This includes periodic inspections to check for any signs of wear or damage. Cleaning the connection and surrounding areas can help prevent contamination and ensure smooth operation. Additionally, ensuring that the connection remains securely fitted will help maintain system integrity and prevent oil leaks.

Troubleshooting Common Issues

Common issues with the Cummins 5289821 Turbocharger Oil Drain Connection may include oil leaks, blockages, or loose fittings. To address these problems, first, inspect the connection for any visible damage or misalignment. If a leak is detected, ensure that the fitting is tightened properly. For blockages, clean the connection and surrounding passages to remove any debris. Regular maintenance and inspections can help prevent these issues from arising.

Cummins Overview

Cummins Inc. is a well-established manufacturer in the automotive industry, known for its high-quality components and innovative solutions. With a rich history of providing reliable and durable products, Cummins has built a strong reputation for excellence. The company’s commitment to manufacturing superior automotive components is evident in its extensive range of products, including the Cummins 5289821 Turbocharger Oil Drain Connection 4.

Turbocharger Oil Drain Connection for Cummins Engines

The turbocharger oil drain connection, part number 5289821, is a component in the lubrication system of certain Cummins engines. This part is designed to facilitate the drainage of oil from the turbocharger, ensuring that the turbocharger operates efficiently and is protected from potential damage due to oil accumulation.

L8.9 Engine

The L8.9 engine is one of the engines that utilizes the turbocharger oil drain connection part number 5289821. This engine is known for its robust performance and reliability, often used in heavy-duty applications. The turbocharger oil drain connection in this engine is strategically placed to allow for the effective removal of oil from the turbocharger, which is essential for maintaining optimal engine performance and longevity.

Integration with Cummins Engines

Cummins engines, including the L8.9, are designed with precision engineering to ensure that components like the turbocharger oil drain connection fit seamlessly. This part is manufactured to meet Cummins’ stringent quality standards, ensuring it performs reliably under various operating conditions. The design of the turbocharger oil drain connection is such that it integrates smoothly with the engine’s lubrication system, providing a secure and efficient means of oil drainage.

The turbocharger oil drain connection is typically located at a point where it can easily access the oil within the turbocharger. This placement is crucial for preventing oil from building up, which could lead to overheating and potential damage to the turbocharger. By ensuring that the oil is effectively drained, the turbocharger oil drain connection helps maintain the overall health and efficiency of the engine.

Role of Part 5289821 Turbocharger Oil Drain Connection in Engine Systems

The part 5289821 Turbocharger Oil Drain Connection is a component in the turbocharger plumbing system of an engine. This component facilitates the drainage of oil from the turbocharger, ensuring that the oil does not accumulate and potentially cause damage to the turbocharger or other engine components.

Integration with Turbocharger Plumbing

-

Oil Drainage Pathway: The Turbocharger Oil Drain Connection (part 5289821) is integrated into the turbocharger plumbing to create a dedicated pathway for oil to be drained from the turbocharger housing. This prevents oil buildup, which can lead to increased temperatures and reduced efficiency.

-

Connection to Oil Return Line: This component is typically connected to the engine’s oil return line. The drained oil is routed back to the oil sump, where it can be recirculated and filtered, maintaining the lubrication system’s integrity.

-

Sealing and Isolation: The Turbocharger Oil Drain Connection ensures a secure seal, preventing oil leaks that could contaminate other engine components or create hazardous conditions. Its design often includes gaskets or O-rings to maintain this seal.

-

Compatibility with Turbocharger Bearings: The drained oil often lubricates the turbocharger’s bearings. Efficient drainage ensures that these bearings remain well-lubricated without excess oil, which could lead to bearing failure.

-

Thermal Management: By allowing for the efficient drainage of oil, part 5289821 helps in thermal management of the turbocharger. Excess oil can retain heat, leading to higher operating temperatures. Proper drainage helps in dissipating this heat more effectively.

-

Maintenance Access: The Turbocharger Oil Drain Connection provides a convenient point for maintenance personnel to check the condition of the oil. This can be indicative of the turbocharger’s wear and the overall health of the lubrication system.

Conclusion

In summary, the Turbocharger Oil Drain Connection (part 5289821) plays a significant role in maintaining the efficiency and reliability of the turbocharger plumbing system. Its proper function ensures that the turbocharger operates within optimal parameters, contributing to the overall performance and longevity of the engine.

-

Hilgers, M. (2023). Vocational Vehicles and Applications. Springer Nature.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩ -

Naunheimer, H., Bertsche, B., Ryborz, J., & Novak, W. (2011). Automotive Transmissions Fundamentals Selection Design and Application. Springer Vieweg.

↩ -

Cummins Inc. (n.d.). L9 CM2350 L123B Transit Bus Applications, Service Manual (5411465).

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.