5311087

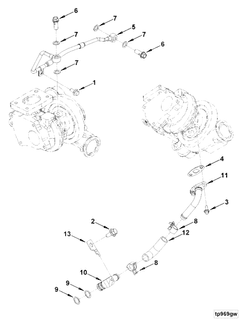

Turbocharger Oil Drain Connection

Cummins®

IN STOCK

1 is currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 5311087 Turbocharger Oil Drain Connection is a component designed to facilitate the drainage of oil from the turbocharger in heavy-duty trucks. Its purpose is to ensure that oil used for lubricating the turbocharger is efficiently drained, maintaining optimal turbocharger performance and longevity. This component is significant in the operation of heavy-duty trucks as it contributes to the overall efficiency and reliability of the engine system 2.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger oil drain connections operate on the principle of allowing used oil to be expelled from the turbocharger housing. This process is vital for preventing oil buildup, which can lead to decreased efficiency and potential damage to the turbocharger. The oil drain connection is typically integrated into the turbocharger system to provide a controlled pathway for oil to exit, ensuring that the turbocharger remains well-lubricated without excess oil accumulation 1.

Role and Function in Truck Operation

This Cummins part plays a role in the overall operation of a truck’s engine by ensuring that the turbocharger is properly lubricated and that excess oil is efficiently drained. This component interacts with the turbocharger’s lubrication system, allowing oil to flow into the turbocharger for lubrication purposes and then exit through the drain connection. Proper drainage helps maintain the turbocharger’s performance, reduces the risk of oil-related issues, and contributes to the engine’s overall efficiency 2.

Key Features

The 5311087 Turbocharger Oil Drain Connection features a design that is tailored to fit specific turbocharger models, ensuring a secure and efficient connection. It is constructed from durable materials that can withstand the high temperatures and pressures within the turbocharger environment. The design includes precise threading and sealing mechanisms to prevent oil leaks and ensure a reliable connection 1.

Benefits

The 5311087 Turbocharger Oil Drain Connection offers several benefits, including improved engine performance through efficient oil drainage, enhanced reliability by reducing the risk of oil-related issues, and increased maintenance efficiency by simplifying the oil drainage process. These benefits contribute to the overall effectiveness and longevity of the turbocharger and the engine system 2.

Installation Process

Installing the 5311087 Turbocharger Oil Drain Connection involves several steps to ensure a proper and secure fit. First, the turbocharger should be inspected for any debris or damage. The drain connection is then aligned with the turbocharger’s oil drain port and threaded into place. It is important to use the appropriate tools to tighten the connection to the manufacturer’s specified torque settings to ensure a leak-free seal 1.

Maintenance and Troubleshooting

Regular maintenance of the 5311087 Turbocharger Oil Drain Connection includes periodic inspections for signs of wear, corrosion, or leaks. Cleaning the connection and surrounding areas can help prevent debris buildup, which could interfere with the drainage process. Common troubleshooting tips include checking for proper torque settings, ensuring the connection is free of obstructions, and verifying that the oil drainage pathway is clear 2.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins is renowned for its innovative solutions and commitment to quality. The company offers a wide range of products designed to meet the needs of various industries, including automotive, construction, and power generation. Cummins’ reputation in the industry is built on its dedication to excellence, reliability, and customer satisfaction 1.

Turbocharger Oil Drain Connection in Cummins Engines

The turbocharger oil drain connection, part number 5311087, is a critical component in the maintenance and operation of certain Cummins engines. This part is integral to the engine’s lubrication system, ensuring that the turbocharger is properly lubricated and that any excess oil is efficiently drained back into the engine’s oil system.

Application in Specific Cummins Engines

QSF2.8 CM2880 F104, QSF2.8 CM2880 F105, and QSF2.8 CM2880 F114

The turbocharger oil drain connection, part number 5311087, is designed to fit seamlessly with the QSF2.8 CM2880 F104, QSF2.8 CM2880 F105, and QSF2.8 CM2880 F114 engines. These engines are part of the Cummins QSF2.8 series, which is known for its reliability and efficiency in various industrial applications.

In these engines, the turbocharger oil drain connection plays a pivotal role in maintaining the health of the turbocharger. It ensures that the oil used to lubricate the turbocharger is returned to the engine’s oil system, preventing oil accumulation within the turbocharger and ensuring optimal performance.

The design of the turbocharger oil drain connection is such that it can be easily integrated into the existing oil system of these engines. This part is manufactured to meet the stringent quality standards set by Cummins, ensuring durability and reliability in demanding environments.

By using the turbocharger oil drain connection part number 5311087, engine operators can maintain the efficiency and longevity of their QSF2.8 CM2880 F104, QSF2.8 CM2880 F105, and QSF2.8 CM2880 F114 engines, ensuring that the turbocharger operates smoothly and without unnecessary wear 1.

Role of Part 5311087 Turbocharger Oil Drain Connection in Engine Systems

The Part 5311087 Turbocharger Oil Drain Connection is an essential component in the maintenance and operation of turbocharger systems within various engine setups. This part facilitates the drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters.

Integration with Turbocharger Systems

In turbocharger systems, the oil drain connection is strategically positioned to allow for the periodic removal of oil that has been used to lubricate the turbocharger’s moving parts. This oil, over time, can become contaminated with particles and degrade, potentially leading to decreased performance and increased wear on the turbocharger components. The 5311087 connection provides a secure and reliable method for draining this oil, allowing for its replacement with fresh lubricant 2.

Interaction with Plumbing Components

The oil drain connection interfaces with the engine’s plumbing system, which includes oil lines, filters, and reservoirs. When the drain connection is activated, typically through a valve or similar mechanism, it allows oil to flow from the turbocharger into the designated drainage area. This process is integral to maintaining the cleanliness and viscosity of the oil, which is vital for the turbocharger’s bearings and other rotating elements 1.

Maintenance and Operational Efficiency

Regular use of the 5311087 Turbocharger Oil Drain Connection contributes to the overall maintenance routine of the engine system. By ensuring that the oil within the turbocharger is regularly refreshed, mechanics and engineers can help prevent issues such as oil sludge buildup, which can impede the turbocharger’s performance and lead to premature failure. Additionally, this component aids in the diagnostic process, as the condition of the drained oil can provide insights into the health of the turbocharger and the effectiveness of the lubrication system 2.

Conclusion

In summary, the Part 5311087 Turbocharger Oil Drain Connection plays a significant role in the upkeep and efficiency of turbocharger systems by facilitating the essential task of oil drainage and replacement. Its integration with both the turbocharger and the engine’s plumbing system underscores its importance in maintaining optimal engine performance and longevity.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.