This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

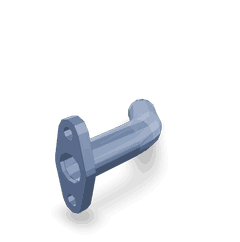

The Turbocharger Oil Drain Connection (5318065) by Cummins is a specialized component designed for use in heavy-duty truck engines. Its purpose is to facilitate the drainage of oil from the turbocharger, ensuring that the system operates efficiently and reliably. This component plays a role in maintaining the performance and longevity of the turbocharger, which is vital for the overall operation of heavy-duty trucks 1.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger oil drain connections are integral to the functioning of turbocharger systems. They allow for the periodic removal of oil that has been used to lubricate the turbocharger’s moving parts. This process helps prevent the buildup of contaminants and ensures that the oil remains effective in reducing friction and wear 2. By maintaining clean and properly lubricated components, the turbocharger can operate at optimal efficiency, contributing to better engine performance and longevity.

Purpose and Role in Truck Operation

The Turbocharger Oil Drain Connection is specifically designed to serve heavy-duty truck engines. It plays a role in the turbocharger system by providing a reliable means to drain oil, which is crucial for maintaining the turbocharger’s performance. By ensuring that the turbocharger remains well-lubricated and free from contaminants, this component contributes to the overall efficiency and reliability of the engine 3.

Key Features

The Turbocharger Oil Drain Connection is characterized by its robust design and the use of high-quality materials. It is engineered to withstand the demanding conditions present in heavy-duty truck engines. The connection features a secure fitting mechanism that ensures a tight seal, preventing oil leaks. Additionally, it is constructed from durable materials that resist corrosion and wear, enhancing its performance and longevity. These features collectively contribute to the component’s reliability and effectiveness in heavy-duty applications 4.

Benefits

The advantages of using the Turbocharger Oil Drain Connection include improved engine performance, enhanced reliability, and potential cost savings for fleet operators. By ensuring that the turbocharger remains properly lubricated and free from contaminants, this component helps maintain optimal engine efficiency. This can lead to better fuel economy and reduced maintenance costs over time. Furthermore, the durability and reliability of the connection contribute to the overall longevity of the turbocharger system, providing fleet operators with a dependable solution for their heavy-duty truck engines.

Troubleshooting and Maintenance

Common issues with the Turbocharger Oil Drain Connection may include oil leaks or blockages. To address these problems, it is recommended to inspect the connection regularly for signs of wear or damage. Ensuring that the fitting is secure and free from debris can help prevent leaks. Routine maintenance practices, such as checking the connection during regular service intervals, can help ensure optimal performance and longevity of the component. Additionally, following the manufacturer’s guidelines for maintenance can further enhance the reliability of the turbocharger system.

Integration with Turbocharger System

The Turbocharger Oil Drain Connection integrates seamlessly with the broader turbocharger system. It interacts with other components such as the turbine and compressor by providing a means to drain oil that has been used to lubricate these parts. This integration ensures that the turbocharger system operates efficiently, with minimal friction and wear on its moving components. The proper functioning of the oil drain connection is vital for the overall performance and reliability of the turbocharger system.

Impact on Engine Performance

The Turbocharger Oil Drain Connection plays a role in engine performance metrics such as horsepower, torque, and fuel efficiency. By ensuring that the turbocharger remains well-lubricated and free from contaminants, this component contributes to maintaining optimal engine efficiency. Proper maintenance of the oil drain connection can help sustain the turbocharger’s performance, leading to consistent engine output and improved fuel economy. This, in turn, supports the overall health and reliability of the engine.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, known for its commitment to innovation and quality. With a rich history of producing reliable and high-performance components, Cummins has established a strong reputation for excellence. The company offers a wide range of products designed to meet the demanding requirements of heavy-duty applications. Cummins’ dedication to advancing technology and maintaining high standards in manufacturing ensures that its components, including the Turbocharger Oil Drain Connection, deliver exceptional performance and durability.

Turbocharger Oil Drain Connection (Part 5318065) in Cummins Engines

The Turbocharger Oil Drain Connection, part number 5318065, is a critical component in the lubrication system of various Cummins engines. This part ensures that oil is efficiently drained from the turbocharger, maintaining optimal engine performance and longevity.

ISB6.7 G CM2180 B118

In the ISB6.7 G CM2180 B118 engine, the Turbocharger Oil Drain Connection plays a vital role in the turbocharger’s lubrication system. It is designed to facilitate the drainage of oil from the turbocharger back to the engine’s oil sump. This connection is essential for maintaining the proper oil level within the turbocharger, preventing oil starvation and ensuring the turbocharger operates smoothly.

ISB6.7 G CM2180 B118 and Similar Engines

The Turbocharger Oil Drain Connection is also compatible with other engines within the Cummins ISB6.7 G series. These engines share similar design principles and lubrication requirements, making the part number 5318065 a versatile solution across multiple engine models. The connection’s design ensures it fits seamlessly into the turbocharger’s oil system, providing a reliable method for oil drainage.

By using the Turbocharger Oil Drain Connection part number 5318065, engine operators can maintain the integrity of their turbocharger’s lubrication system, ensuring consistent performance and reducing the risk of component failure.

Role of Part 5318065 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection, identified by part number 5318065, is an integral component in the efficient operation of turbocharged engine systems. This part facilitates the necessary drainage of oil from the turbocharger, ensuring that the lubrication system remains effective and that the turbocharger operates within optimal parameters.

Integration with Turbocharger

In turbocharged engines, the turbocharger relies on a continuous supply of oil for lubrication and cooling. The Turbocharger Oil Drain Connection is strategically positioned to allow the used oil, which has circulated through the turbocharger’s bearings and other moving parts, to be efficiently returned to the engine’s oil sump. This process is vital for maintaining the integrity of the turbocharger’s internal components, preventing overheating, and ensuring smooth operation.

Interaction with Plumbing Systems

The Turbocharger Oil Drain Connection is also a key interface within the engine’s plumbing system. It connects to the oil return lines, which are part of the engine’s overall lubrication circuit. This connection ensures that the drained oil is properly channeled back into the sump, where it can be recirculated and re-filtered. The design of this connection must accommodate the pressures and temperatures inherent in the oil system, ensuring a reliable and leak-free seal.

Importance in Maintenance and Efficiency

Regular drainage of oil from the turbocharger is essential for maintaining engine efficiency and longevity. The Turbocharger Oil Drain Connection plays a significant role in this process by providing a dedicated pathway for oil to exit the turbocharger. This helps in reducing the risk of oil contamination and buildup, which can lead to decreased performance and potential damage to the turbocharger and other engine components.

Enhanced System Reliability

By ensuring that the oil drain process is smooth and uninterrupted, the Turbocharger Oil Drain Connection contributes to the overall reliability of the engine system. It allows for consistent lubrication, which is paramount for the high-speed operation of the turbocharger’s turbine and compressor wheels. This, in turn, supports the engine’s power output and responsiveness, making the Turbocharger Oil Drain Connection a fundamental element in the turbocharged engine’s design.

Conclusion

The Turbocharger Oil Drain Connection (5318065) by Cummins is a critical component in maintaining the efficiency and reliability of heavy-duty truck engines. By facilitating the drainage of oil from the turbocharger, this part ensures that the lubrication system remains effective, preventing overheating and ensuring smooth operation. Its robust design and integration with the turbocharger system contribute to enhanced engine performance and longevity. Regular maintenance and proper use of this component are essential for sustaining the overall health and reliability of the engine.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.