This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

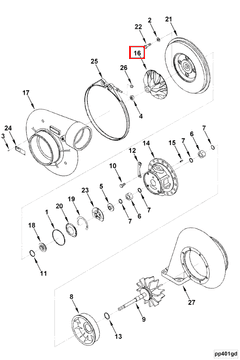

The turbocharger compressor impeller, specifically Part #5323926 by Cummins, is a vital component in heavy-duty truck engines. Cummins, a leading manufacturer in the diesel engine and components industry, designs this impeller to enhance engine performance and efficiency. This component is integral to the turbocharger system, which plays a role in optimizing the engine’s power output and fuel efficiency 1.

Basic Concepts of Turbocharger Compressor Impellers

Turbochargers are devices that increase an engine’s power output by forcing extra air into the combustion chamber. The compressor impeller, a key part of the turbocharger, is responsible for compressing the intake air. This compression allows more air to enter the engine, which, when combined with fuel, results in a more powerful combustion process. The efficiency and design of the compressor impeller directly influence the turbocharger’s performance and, consequently, the engine’s overall efficiency and power output 2.

Purpose and Function of the 5323926 Turbocharger Compressor Impeller

This part is designed to play a specific role in the operation of a truck engine. It enhances the engine’s efficiency and power output by effectively compressing the intake air. This compression leads to a denser air charge entering the combustion chamber, allowing for more efficient fuel combustion and, as a result, improved engine performance. The impeller’s design is tailored to meet the demanding requirements of heavy-duty truck engines, ensuring reliable and efficient operation under various conditions 3.

Key Features of the 5323926 Turbocharger Compressor Impeller

This Cummins part is characterized by its robust design and construction. It is manufactured using high-quality materials that ensure durability and performance under high-stress conditions. The blade design of the impeller is optimized for efficient air compression, contributing to the overall effectiveness of the turbocharger. Advanced manufacturing processes are employed to ensure precision and reliability in the impeller’s performance.

Benefits of Using the 5323926 Turbocharger Compressor Impeller

Utilizing this part offers several advantages. It contributes to increased engine efficiency, allowing for higher power output without a proportional increase in fuel consumption. This results in improved fuel economy, making it a cost-effective solution for heavy-duty truck operators. Additionally, the enhanced air compression leads to more complete fuel combustion, reducing emissions and promoting environmental sustainability.

Troubleshooting and Maintenance Suggestions

To ensure the longevity and optimal performance of this part, regular maintenance and troubleshooting are recommended. Common issues may include impeller fouling or damage, which can affect turbocharger efficiency. Diagnostic tips include monitoring engine performance and turbocharger operation for signs of decreased efficiency. Maintenance practices should include regular inspections and cleaning of the impeller and turbocharger system to prevent buildup and ensure smooth operation.

Integration With Cummins Engines

This part is designed to work seamlessly with Cummins engines. It incorporates specific compatibility features and design considerations that ensure optimal performance when integrated with Cummins engine systems. This integration enhances the engine’s efficiency and power output, demonstrating the impeller’s role in Cummins’ commitment to innovation and quality in diesel engine technology.

Technological Advancements in Turbocharger Compressor Impellers

Recent technological advancements in turbocharger compressor impellers, including innovations by Cummins, have significantly enhanced performance and reliability. These advancements focus on improving the efficiency of air compression, reducing wear and tear on the impeller, and increasing the overall durability of the turbocharger system. Cummins continues to lead in developing cutting-edge technologies that push the boundaries of what turbochargers can achieve in terms of engine performance and efficiency.

Environmental Impact and Efficiency

The use of advanced turbocharger compressor impellers like the 5323926 contributes to reduced emissions and improved overall engine efficiency. By enabling more complete fuel combustion, these impellers help minimize the release of harmful pollutants into the atmosphere. Furthermore, the increased efficiency of the engine leads to lower fuel consumption, which is beneficial for both economic and environmental reasons.

Compatibility of the 5323926 Turbocharger Compressor Impeller

The 5323926 turbocharger compressor impeller is designed to fit a range of engine models, ensuring optimal performance and efficiency across various applications. This part is engineered to work seamlessly with the following engines:

- Cummins 6B5.9 Engines: Known for robust performance and reliability.

- Cummins K19 and K38 Engines: Part of Cummins’ K-series line, renowned for durability and efficiency.

- Cummins K50 Engines: Designed for heavy-duty applications.

- Cummins QSK19 and CM850 Engines: Part of the Cummins QSK series, known for versatility and performance.

- Cummins MCRS Engines: Engineered for high-performance applications.

By ensuring compatibility with these diverse engine models, the 5323926 turbocharger compressor impeller provides a reliable and efficient solution for maintaining and enhancing engine performance across various applications.

Role of the 5323926 Turbocharger Compressor Impeller in Engine Systems

The 5323926 turbocharger compressor impeller is an integral component within the turbocharger system, designed to enhance engine performance by increasing the mass flow rate of air entering the combustion chamber. Its operation is closely tied to several other components within the engine system.

Interaction with Key Components

- Turbocharger: The impeller is a core element of the turbocharger, responsible for compressing the intake air.

- Intake Manifold: The compressed air from the impeller is channeled through the intake manifold.

- Cylinder Head: The compressed air plays a vital role in the combustion process.

- Injector: The performance of the injector is enhanced by the increased air pressure provided by the impeller.

- Aftercooler and Aftercooler Core: Post-compression, the air often passes through an aftercooler to reduce its temperature.

- Aftercooler Plumbing: Efficient plumbing ensures minimal pressure loss.

- Heat Exchanger and HX80 Turbocharger: The impeller ensures that the air entering the heat exchanger is at an optimal pressure and temperature.

- Camshaft and Camshaft and Gear: The performance gains from the impeller can place additional demands on the camshaft and its associated gear.

- Connecting Rod and Piston: The increased air pressure from the impeller leads to higher combustion pressures within the cylinders.

- Oil Connection, Oil Control Valve, and Oil Manifold: The turbocharger, including the impeller, requires precise lubrication.

- Rocker Housing and Protective Cover: These components shield the impeller and other turbocharger parts from external contaminants and mechanical damage.

In summary, the 5323926 turbocharger compressor impeller significantly influences various engine components, enhancing overall performance, efficiency, and power output. Its integration within the engine system requires careful consideration of the interactions with other components to achieve the desired performance gains.

Conclusion

The 5323926 turbocharger compressor impeller by Cummins is a critical component in enhancing the performance and efficiency of heavy-duty truck engines. Its robust design, advanced features, and compatibility with various Cummins engines make it a valuable asset for operators seeking improved engine performance and reduced environmental impact. Regular maintenance and understanding its role within the engine system are essential for maximizing its benefits.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.