This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

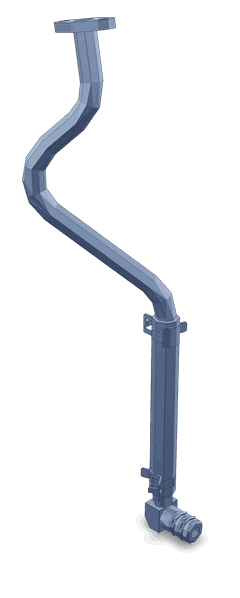

The Turbocharger Oil Drain Connection (5332488) manufactured by Cummins is a component designed to facilitate the drainage of oil from the turbocharger. This part is integral to the operation of commercial trucks, ensuring that the turbocharger functions efficiently and remains in optimal condition. By allowing for the regular removal of oil, it helps maintain the turbocharger’s performance and longevity 1.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger oil drain connections operate on the principle of allowing used oil to be expelled from the turbocharger system. This process is vital for the turbocharger’s health, as it prevents the buildup of contaminants and ensures that the lubricant remains effective. The connection is typically located at the lowest point of the turbocharger’s oil system, enabling gravity to assist in the drainage process. Regular oil drainage helps in reducing wear and tear on the turbocharger components, thereby contributing to the overall efficiency of the engine 2.

Purpose and Function

The Turbocharger Oil Drain Connection serves a specific role in the operation of a truck’s engine. It is designed to allow for the periodic drainage of oil from the turbocharger, which is crucial for maintaining the turbocharger’s efficiency. By ensuring that clean oil circulates within the turbocharger, this connection helps in reducing friction and heat, which are common causes of turbocharger failure. Moreover, it contributes to the engine’s overall performance by ensuring that the turbocharger operates within its optimal parameters 3.

Key Features

The Turbocharger Oil Drain Connection is characterized by several design elements and materials that enhance its performance and durability. It is constructed from high-quality materials that are resistant to corrosion and wear, ensuring a long service life. The design includes precise threading and sealing mechanisms to prevent oil leaks, which could lead to engine damage. Additionally, the connection is engineered to be compatible with a variety of Cummins turbocharger models, offering versatility in application 4.

Benefits

Utilizing the Turbocharger Oil Drain Connection offers several advantages. It contributes to improved turbocharger efficiency by facilitating the removal of contaminated oil, which can otherwise lead to increased friction and wear. Enhanced engine performance is another benefit, as a well-maintained turbocharger can operate more effectively, leading to better fuel efficiency and power output. Furthermore, the connection increases the reliability of the turbocharger system by ensuring that it remains clean and free from debris.

Installation and Compatibility

Proper installation of the Turbocharger Oil Drain Connection is vital for its effective operation. It should be installed according to the manufacturer’s guidelines to ensure a secure fit and proper function. Compatibility with various Cummins engines and turbocharger models is a key consideration, as it ensures that the connection can be used across a wide range of applications without the need for modifications.

Maintenance and Troubleshooting

Routine maintenance of the Turbocharger Oil Drain Connection is important for its optimal performance. This includes regular checks for leaks, ensuring that the connection is tight, and verifying that the drainage process is functioning correctly. Troubleshooting common issues, such as oil leaks or difficulty in draining, may involve inspecting the connection for damage, ensuring that the sealing mechanisms are intact, and verifying that the turbocharger’s oil system is free from obstructions.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emissions control technologies. With a strong reputation in the commercial truck industry, Cummins is known for its commitment to innovation, quality, and customer satisfaction. The company’s product offerings are designed to meet the demanding requirements of commercial applications, ensuring reliability and performance in various operating conditions.

Role of Part 5332488 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection (5332488) is an essential component in the efficient operation of turbochargers within engine systems. This component is specifically designed to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains effective and that the turbocharger operates within optimal parameters.

Integration with Turbocharger

In the context of a turbocharger, the oil drain connection is integral to the lubrication circuit. Turbochargers require a constant supply of oil to lubricate the rotating components, such as the turbine and compressor wheels. Over time, this oil can become contaminated with soot and other particles, which can impair its lubricating properties. The oil drain connection allows for the periodic removal of this used oil, ensuring that fresh, clean oil is circulated through the system. This helps maintain the efficiency and longevity of the turbocharger.

Interaction with Plumbing Systems

The oil drain connection also plays a significant role in the engine’s plumbing system. It is typically connected to a network of hoses and pipes that transport oil to and from various components. The connection point must be secure and leak-proof to prevent oil loss and contamination. In high-performance engines, where oil temperatures and pressures can be extreme, the integrity of this connection is particularly important.

Maintenance and Operational Efficiency

Regular maintenance of the oil drain connection is vital for the operational efficiency of the engine. During servicing, mechanics will often disconnect this part to drain the oil from the turbocharger. This process not only helps in maintaining the turbocharger but also provides an opportunity to inspect the oil for signs of wear or contamination, which can indicate potential issues within the turbocharger or the engine’s lubrication system.

Enhanced Performance and Reliability

By ensuring that the turbocharger is properly lubricated and that old oil is efficiently drained, the oil drain connection contributes to the overall performance and reliability of the engine. It helps in reducing the risk of turbocharger failure, which can be costly and time-consuming to repair. Moreover, it aids in maintaining the engine’s power output and fuel efficiency, as a well-lubricated turbocharger can operate more smoothly and with less friction.

Conclusion

The Turbocharger Oil Drain Connection (5332488) is a key component in the maintenance and operation of turbochargers within engine systems. Its proper function ensures that the turbocharger remains well-lubricated, contributing to the engine’s performance, efficiency, and reliability.

-

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Dixon, J. C. (1996). Tyres Suspension and Handling Second Edition. SAE International.

↩ -

Bari, S. (2013). Diesel Engine Combustion, Emissions and Condition Monitoring. InTech.

↩ -

Sobey, E. (2009). A Field Guide to Automotive Technology. Chicago Review Press.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.