This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

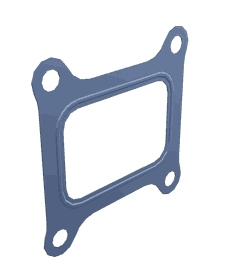

Turbocharger gaskets are vital for the efficient operation of commercial trucks, ensuring the turbocharger system functions correctly. This article examines the 3069177 turbocharger gasket by Cummins, detailing its role, features, and benefits. It also provides guidance on troubleshooting and maintenance, and offers an overview of Cummins Inc. and its contributions to the commercial truck industry.

Basic Concepts of Turbocharger Gaskets

Turbocharger gaskets seal the connection between the turbocharger and the engine, maintaining system integrity by preventing leaks and ensuring efficient airflow 1. The materials used, such as metal, composite, or rubber, contribute to their sealing capabilities and durability. Each material offers different properties that can affect the gasket’s performance under various operating conditions 2.

Purpose of the 3069177 Turbocharger Gasket

The 3069177 turbocharger gasket by Cummins is designed to create a secure seal between the turbocharger and the engine. This seal is essential for maintaining efficient airflow and preventing leaks that could impact engine performance. By ensuring a tight connection, the gasket helps to optimize the turbocharger’s operation, contributing to the overall efficiency and reliability of the engine 3.

Key Features

The 3069177 turbocharger gasket is engineered with specific design and construction features that enhance its performance. It is compatible with Cummins engines, ensuring a precise fit and reliable operation. The gasket is made from durable materials that can withstand the high temperatures and pressures within the engine compartment. Unique design elements, such as reinforced edges or multi-layer construction, may be incorporated to improve its sealing capabilities and longevity.

Benefits

Using the 3069177 turbocharger gasket offers several advantages. It contributes to improved engine efficiency by maintaining a secure seal and preventing leaks. The durable construction of the gasket enhances its resistance to wear and tear, reducing the risk of failure. Additionally, the gasket’s design and materials help to ensure reliable performance, contributing to the overall reliability and efficiency of the engine.

Troubleshooting and Maintenance

Regular maintenance and timely replacement of the turbocharger gasket are important for optimal engine performance. Common issues, such as leaks or signs of wear, should be addressed promptly to prevent further damage. Maintenance checks should include inspecting the gasket for any signs of damage or wear and ensuring that it is properly installed. Following best practices for replacement, such as using the correct torque specifications and ensuring a clean mating surface, will help to maintain the integrity of the seal and the efficiency of the engine.

Compatibility with Cummins Engines

The turbocharger gasket part number 3069177, manufactured by Cummins, is designed to fit a variety of Cummins engines. This gasket is crucial for ensuring a proper seal between the turbocharger and the engine, preventing leaks and maintaining optimal performance. Here are the engines with which this gasket is compatible:

G855 Series

- G855

- G855 CM558

- GTA855 CM558 (CM2358)

K38 Series

- K38

N14 Series

- N14 CELECT

- N14 CELECT PLUS

- N14 G

- N14 MECHANICAL

- QSN14 CM876 N103

NH/NT Series

- NH/NT 855

V Series

- V28

- V903

This gasket is engineered to meet the specific sealing requirements of these engines, ensuring a reliable fit and performance across the range of applications.

Role of the 3069177 Turbocharger Gasket in Engine Systems

The 3069177 turbocharger gasket is an essential component in ensuring the efficient operation of various engine systems. Its primary function is to create a seal between the turbocharger and other engine components, preventing leaks and maintaining optimal performance. Here’s how it integrates with the provided components:

Integration with Key Components

Turbocharger and Turbocharger Mounting

The turbocharger gasket fits between the turbocharger and its mounting points. This seal is vital for the turbocharger’s secure attachment to the engine, ensuring that no exhaust gases escape, which could lead to performance issues or damage.

Exhaust Manifold and Exhaust Outlet

When installed between the turbocharger and the exhaust manifold or exhaust outlet, the gasket ensures that exhaust gases flow smoothly into the turbocharger. This efficient flow is necessary for the turbocharger to spin at the correct speed, enhancing engine performance.

Aftercooler and Intercooler Systems

In systems equipped with an aftercooler or intercooler, the turbocharger gasket seals the connection between the turbocharger and these cooling components. This seal is important for maintaining the integrity of the compressed air flow, which is cooled before entering the engine, improving combustion efficiency.

Cylinder Head and Short Block

In engines where the turbocharger is mounted directly to the cylinder head or integrated into the short block, the gasket ensures a tight seal. This prevents any air leaks that could disrupt the engine’s air-fuel ratio, affecting overall performance and efficiency.

Collector Mounting and Exhaust Collector

For engines with a collector mounting turbocharger setup, the gasket seals the connection between the turbocharger and the exhaust collector. This ensures that the pressurized air is delivered efficiently to the engine’s intake system.

Overhaul Gasket Set and Overhaul Kit

During engine overhauls, the turbocharger gasket is often included in overhaul gasket sets and kits. Its replacement ensures that all seals within the engine are fresh, contributing to the engine’s restored performance and reliability.

Plumbing and Connection Points

In complex engine systems with multiple plumbing connections, the gasket ensures that all connections between the turbocharger and other components, such as the intake and exhaust systems, are sealed properly. This is essential for maintaining the engine’s overall efficiency and performance.

Additional Components

- EBM: Performance Parts: When upgrading with performance parts, the turbocharger gasket may be replaced to accommodate higher pressures and temperatures, ensuring the new components function optimally.

- Upper Engine Brake Set: In engines equipped with an upper engine brake, the gasket ensures that the turbocharger operates efficiently under varying load conditions, contributing to the brake’s effectiveness.

- Tachometer Parts Kit: Although indirectly related, ensuring the turbocharger operates efficiently with the help of the gasket can provide more accurate readings from tachometers, as engine speed and performance are closely linked.

The turbocharger gasket’s role in these systems underscores its importance in maintaining the engine’s performance, efficiency, and reliability.

About Cummins

Cummins Inc. is a leading manufacturer in the commercial truck industry, known for its commitment to quality and innovation in engine components. The company has a long history of developing reliable and efficient engine solutions, including turbocharger gaskets. Cummins’ dedication to research and development ensures that its products meet the demanding requirements of commercial truck applications, providing customers with durable and high-performing components.

Conclusion

The 3069177 turbocharger gasket by Cummins is a critical component for maintaining the efficiency and reliability of commercial truck engines. Its durable construction, precise fit, and compatibility with various Cummins engines make it an essential part for ensuring optimal engine performance. Regular maintenance and timely replacement of this part are vital for preventing leaks and maintaining the integrity of the turbocharger system.

-

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Brach, R. M. (2023). SAE International’s Dictionary of Vehicle Accident Reconstruction and Automotive Safety. SAE Books.

↩ -

Denton, T., & Pells, H. (2022). Automotive Technician Training Theory. Routledge.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.