This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

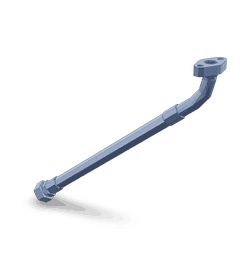

The Turbocharger Oil Drain Connection, identified by part number 3103332, is a component designed for heavy-duty truck engines by Cummins Inc. This part is integral to the turbocharger system, contributing to the overall performance and efficiency of the engine.

Basic Concepts of Turbocharger Oil Drain Connection

Turbochargers increase an engine’s power output by forcing extra air into the combustion chamber, a process known as forced induction 1. The turbocharger consists of a turbine and a compressor connected by a shaft. The oil drain connection within the turbocharger system allows for the drainage of lubricating oil, ensuring that the internal components remain properly lubricated and cooled.

Purpose of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection (3103332) facilitates the drainage of lubricating oil from the turbocharger, maintaining its lubrication and efficiency. Proper drainage prevents oil buildup, which can lead to decreased performance and potential damage to the turbocharger.

Key Features

This Cummins part is constructed from high-quality materials resistant to high temperatures and pressures. Its design ensures a secure fit, preventing leaks and ensuring efficient oil drainage. It may also include a filter to trap contaminants, further protecting the turbocharger.

Benefits

The benefits of the Turbocharger Oil Drain Connection include improved engine performance, enhanced turbocharger longevity, and simplified maintenance procedures. Proper lubrication and prevention of oil buildup contribute to the efficient operation of the turbocharger and the overall performance of the engine.

Installation Process

Installing the Turbocharger Oil Drain Connection involves ensuring the turbocharger and surrounding areas are clean, aligning the connection with the oil drain port, securing it in place, and performing a visual inspection to confirm proper installation and no leakage.

Troubleshooting Common Issues

Common issues with Turbocharger Oil Drain Connections include leaks, blockages, and contamination. Solutions may involve tightening the connection, cleaning the drain path, or replacing the connection if damaged.

Maintenance Tips

To ensure the longevity and optimal performance of the Turbocharger Oil Drain Connection, routine maintenance practices are recommended. This includes regular inspection for wear or damage, cleaning the connection and surrounding areas, and draining the oil at recommended intervals.

Cummins: A Brief Overview

Cummins Inc. is a global power leader known for its quality, reliability, and innovation in the commercial truck industry. The company offers a wide range of products and services, including engines, powertrains, and aftermarket parts, designed to meet the demanding needs of heavy-duty applications.

Application in ISM CM570/870 and ISM CM876 Engines

In the ISM CM570/870 and ISM CM876 engines, the Turbocharger Oil Drain Connection plays a vital role in maintaining the health of the turbocharger by allowing for the controlled drainage of oil, preventing accumulation and potential damage.

Integration with Turbocharger Plumbing

The Turbocharger Oil Drain Connection serves as a vital link between the turbocharger and the engine’s oil return system, facilitating the controlled return of oil used to lubricate the turbocharger’s bearings and other moving parts.

Interaction with Other Components

- Turbocharger Bearings: Efficient drainage of oil is essential for maintaining bearing health and turbocharger longevity.

- Oil Return System: The connection interfaces with the engine’s oil return system, allowing used oil to be returned to the oil sump for recirculation and re-filtering.

- Turbocharger Housing: The connection is housed within the turbocharger’s casing, designed to withstand high temperatures and pressures.

- Oil Filter: Drained oil is routed back to the oil sump for re-filtering, removing contaminants picked up during the lubrication cycle.

Operational Benefits

The Turbocharger Oil Drain Connection offers enhanced lubrication efficiency, improved turbocharger performance, and reduced maintenance requirements by ensuring efficient oil drainage.

Conclusion

The Turbocharger Oil Drain Connection (part 3103332) plays a significant role in the turbocharger plumbing system, facilitating efficient oil drainage and contributing to the overall performance and reliability of the turbocharger and engine system.

-

Wang, Yushu. Introduction to Engine Valvetrains. SAE International, 2007.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.