This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection, identified by part number 3255709, is a component manufactured by Cummins, a leading name in the commercial truck industry. This part is integral to the operation of heavy-duty truck engines, particularly in the context of turbocharger systems. Understanding its function and significance is key to maintaining optimal engine performance and longevity.

Basic Concepts of Turbocharger Oil Drain Connection

Turbochargers are devices that increase the efficiency and power output of diesel engines by compressing the intake air before it enters the combustion chamber. This process relies on the turbocharger’s turbine, which is spun by exhaust gases. Effective lubrication is vital for the turbocharger’s operation, as it reduces friction and wear on moving parts. The oil drain connection is a component that facilitates the circulation and drainage of oil within the turbocharger system, ensuring that the lubricant is efficiently managed and maintained 1.

Purpose of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection, part number 3255709, plays a role in the turbocharger system by allowing for the controlled drainage of oil. This process is crucial for maintaining the correct oil level within the turbocharger, which in turn supports the lubrication of critical components. Proper oil circulation and drainage contribute to the maintenance of optimal turbocharger performance, ensuring that the engine operates efficiently and reliably 2.

Key Features

The Turbocharger Oil Drain Connection is designed with specific features that enhance its functionality. Constructed from durable materials, it is built to withstand the high temperatures and pressures present in turbocharger systems. The connection type is engineered for a secure fit, ensuring that oil is effectively drained without leaks. Additionally, the design may include features that simplify installation and maintenance, contributing to the overall ease of use.

Benefits

Incorporating the Turbocharger Oil Drain Connection into a turbocharger system offers several advantages. It contributes to improved engine efficiency by ensuring that the turbocharger operates within its optimal lubrication parameters. This, in turn, can extend the turbocharger’s lifespan by reducing wear on its components. Furthermore, the efficient management of oil within the system enhances overall engine performance, leading to better fuel economy and reduced emissions 3.

Installation Process

Installing the Turbocharger Oil Drain Connection requires careful attention to detail to ensure proper integration with the turbocharger system. The process involves preparing the turbocharger for installation, connecting the oil drain fitting securely, and verifying that there are no leaks. Tools required may include wrenches and sealant, depending on the specific design of the connection. Following manufacturer guidelines during installation is recommended to ensure compatibility and performance.

Maintenance and Troubleshooting

Regular maintenance of the Turbocharger Oil Drain Connection is important for its effective operation. This includes checking for leaks, ensuring the connection is secure, and monitoring oil levels within the turbocharger system. Common issues may include oil leaks or blockages, which can often be addressed by tightening connections or cleaning the system. Adhering to recommended maintenance schedules can help prevent more serious problems and ensure the longevity of the turbocharger system 4.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality and innovation in the commercial truck industry. The company’s commitment to excellence is evident in its wide range of products, which are designed to meet the demanding requirements of heavy-duty applications. Cummins’ focus on quality and customer satisfaction underscores its position as a trusted provider of engine components, including the Turbocharger Oil Drain Connection.

Turbocharger Oil Drain Connection in Cummins Engines

The Turbocharger Oil Drain Connection, part number 3255709, is a critical component in the maintenance and operation of certain Cummins engines. This part is designed to facilitate the drainage of oil from the turbocharger, ensuring that the system operates efficiently and prolonging the life of the turbocharger itself.

Application in N14 CELECT PLUS Engines

In the N14 CELECT PLUS engine, the Turbocharger Oil Drain Connection is integral to the engine’s lubrication system. This engine, known for its robust performance and reliability, benefits from the precise function of the oil drain connection. The part ensures that any excess oil within the turbocharger is effectively removed, preventing oil build-up that could lead to overheating and potential damage.

Grouping of Engines

The Turbocharger Oil Drain Connection, part number 3255709, is compatible with a range of Cummins engines. While the N14 CELECT PLUS is specifically noted, this part is also applicable to other models within the Cummins engine family that share similar design and operational characteristics. These engines often include those in the C, K, and Q series, where the turbocharger oil management system is similarly structured.

Importance of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection is essential for maintaining the health of the turbocharger. By allowing the drainage of oil, it helps to:

- Prevent oil contamination within the turbocharger.

- Reduce the risk of oil-related wear and tear.

- Ensure optimal performance and longevity of the turbocharger.

This part is a testament to Cummins’ commitment to providing high-quality, reliable components that enhance the overall efficiency and durability of their engines.

Role of Part 3255709 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection, identified by part number 3255709, is integral to the efficient operation of turbocharged engine systems. This component facilitates the drainage of oil from the turbocharger, ensuring that the lubrication system remains effective and that the turbocharger operates within optimal parameters.

Integration with Turbocharger

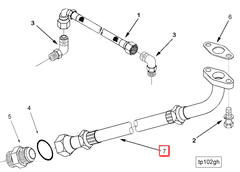

In turbocharged engines, the turbocharger is a pivotal component that compresses the intake air, allowing more air to enter the combustion chamber. This increased air volume enhances engine performance and efficiency. The Turbocharger Oil Drain Connection is strategically positioned to allow for the periodic removal of oil that has been used to lubricate the turbocharger’s moving parts. This ensures that the oil does not become contaminated or degraded, which could lead to increased friction and potential turbocharger failure.

Interaction with Plumbing Systems

The Turbocharger Oil Drain Connection is also a key interface within the engine’s plumbing system. It is connected to the oil return lines, which transport used oil back to the sump or oil pan. This connection point is designed to be easily accessible, allowing for routine maintenance and inspection. The efficient drainage of oil helps maintain the integrity of the lubrication system, preventing oil starvation and ensuring consistent oil pressure throughout the engine.

Maintenance and Operational Benefits

Regular use of the Turbocharger Oil Drain Connection allows for the inspection of oil quality, which can provide insights into the overall health of the turbocharger and the engine. Clean, uncontaminated oil is indicative of proper turbocharger function, while discolored or contaminated oil may signal issues that require attention. Additionally, the connection point simplifies the oil change process, allowing for quick and efficient maintenance procedures.

Conclusion

In summary, the Turbocharger Oil Drain Connection (part 3255709) plays a significant role in maintaining the performance and longevity of turbocharged engine systems by ensuring effective oil management and facilitating routine maintenance. Its integration into the turbocharger and engine plumbing systems highlights its importance in the overall operation and health of the engine.

-

Stone, Richard. Introduction to Internal Combustion Engines, Fourth Edition. Macmillan, 2012.

↩ -

Nunney, MJ. Light and Heavy Vehicle Technology, Fourth Edition. Butterworth-Heinemann, 2007.

↩ -

Rendle, Steve, and Martynn Randall. Haynes Diesel Engine Systems and Data Book. Haynes Publishing, 2000.

↩ -

Bell, Joseph A. Modern Diesel Technology Electricity Electronics. Delmar Cengage Learning, 2014.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.