3328643

Turbocharger Oil Drain Connection

Cummins®

AVAILABLE

3 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

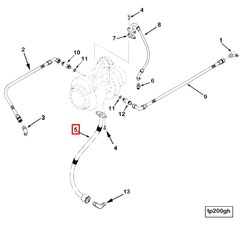

The Turbocharger Oil Drain Connection, identified by Part #3328643, is a component manufactured by Cummins, a leader in the commercial truck engine industry. This part is integral to the maintenance and operation of heavy-duty truck engines, particularly those equipped with turbochargers. Its role is to facilitate the drainage of oil from the turbocharger, ensuring the system operates efficiently and reliably.

Basic Concepts of Turbocharger Oil Drain Connection

Turbochargers are devices that increase an engine’s power output by forcing extra air into the combustion chamber. This process, known as forced induction, enhances the engine’s efficiency and performance. However, the high-speed rotation of the turbocharger’s components generates heat, necessitating an oil lubrication system to reduce friction and wear. The Turbocharger Oil Drain Connection is a critical component in this system, allowing for the periodic removal of used oil, which can become contaminated with soot and other particles, ensuring the turbocharger remains lubricated with clean oil 1.

Purpose and Function

The Turbocharger Oil Drain Connection serves a pivotal role in the turbocharger’s oil management system. It allows for the controlled drainage of oil from the turbocharger, which is crucial for maintaining the efficiency and longevity of the turbocharger. By ensuring that the turbocharger is lubricated with clean oil, this component helps to prevent wear and tear on the turbocharger’s moving parts, thereby contributing to the overall reliability and performance of the engine 2.

Key Features

The Turbocharger Oil Drain Connection is designed with several key features that enhance its performance and durability. It is constructed from high-quality materials that can withstand the high temperatures and pressures within the turbocharger system. The design of the connection ensures a secure fit, preventing leaks and ensuring that oil is effectively drained from the turbocharger. Additionally, the connection is engineered to be compatible with Cummins turbochargers, ensuring seamless integration into the engine system 3.

Benefits

Incorporating the Turbocharger Oil Drain Connection into a truck’s engine system offers several benefits. It contributes to improved engine performance by ensuring that the turbocharger operates with clean oil, reducing the risk of wear and enhancing efficiency. Additionally, by facilitating the regular drainage of used oil, it reduces the maintenance needs associated with the turbocharger, leading to lower overall maintenance costs. Furthermore, the connection enhances the reliability of the turbocharger system, contributing to the longevity of the engine.

Installation Process

Installing the Turbocharger Oil Drain Connection requires careful attention to detail to ensure proper fitment and function. The process involves disconnecting the old drain connection, if present, and attaching the new connection to the turbocharger. It is important to use the appropriate tools and follow safety precautions, such as wearing protective gloves and eyewear, to prevent injury. Additionally, ensuring that all connections are secure and leak-free is crucial for the system’s integrity.

Troubleshooting Common Issues

Common issues associated with the Turbocharger Oil Drain Connection may include leaks or difficulty in draining oil. These problems can often be traced back to improper installation or wear and tear on the connection. Diagnostic steps may involve inspecting the connection for signs of damage or wear, ensuring that it is securely attached, and checking for leaks in the system. Solutions may range from tightening connections to replacing the drain connection if it is found to be faulty.

Maintenance Tips

Regular maintenance of the Turbocharger Oil Drain Connection is key to ensuring its longevity and optimal performance. This includes periodic inspection of the connection for signs of wear or damage, ensuring that it remains securely attached, and cleaning the area around the connection to prevent the buildup of dirt or debris. Additionally, following the manufacturer’s recommended intervals for oil drainage and replacement can help maintain the efficiency and reliability of the turbocharger system.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history dating back to 1919, Cummins has established a strong reputation in the commercial truck industry for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range includes engines, powertrains, and aftermarket parts, all designed to meet the demanding requirements of heavy-duty applications. Cummins’ dedication to excellence in engine components is evident in its Turbocharger Oil Drain Connection, a testament to the company’s ongoing pursuit of technological advancement and reliability in the automotive sector.

Turbocharger Oil Drain Connection (Part 3328643) Compatibility with Cummins Engines

The Turbocharger Oil Drain Connection (Part 3328643) by Cummins is a critical component designed to ensure the efficient and reliable operation of turbochargers across various engine models. This part is integral to the oil management system, facilitating the drainage of oil from the turbocharger back into the engine’s lubrication system. Its compatibility spans several Cummins engine models, ensuring that it fits seamlessly into the oil management infrastructure of these engines.

ISM CM570, QSM11 CM570

The ISM CM570 and QSM11 CM570 engines are part of Cummins’ lineup of high-performance, fuel-efficient diesel engines. These engines are designed for heavy-duty applications, and the Turbocharger Oil Drain Connection (Part 3328643) is engineered to meet the rigorous demands of these environments. The part’s design ensures that it can handle the high-pressure and high-temperature conditions typical of these engines, contributing to the overall reliability and longevity of the turbocharger.

L10 Engines

The L10 engine series, including L10 CELECT, L10 GAS, and L10 MECHANICAL variants, represents a range of versatile and robust engines suitable for various applications. The Turbocharger Oil Drain Connection (Part 3328643) is compatible with these engines, providing a reliable method for oil drainage from the turbocharger. This compatibility ensures that the oil management system operates efficiently, regardless of the specific variant of the L10 engine in use.

M11 Engines

The M11 engine series, which includes M11 CELECT and M11 CELECT PLUS models, is known for its advanced technology and high performance. The Turbocharger Oil Drain Connection (Part 3328643) is designed to integrate seamlessly with these engines, supporting the turbocharger’s oil management system. This part’s design ensures that it can handle the specific demands of the M11 engines, contributing to their efficiency and reliability.

M11 MECHANICAL

The M11 MECHANICAL engine is a variant of the M11 series, known for its mechanical reliability and performance. The Turbocharger Oil Drain Connection (Part 3328643) is compatible with this engine, ensuring that the turbocharger’s oil management system operates effectively. This compatibility is crucial for maintaining the engine’s performance and longevity, especially in demanding applications.

Role of Part 3328643 Turbocharger Oil Drain Connection in Engine Systems

The Part 3328643 Turbocharger Oil Drain Connection is an essential component in maintaining the efficiency and reliability of engine systems that incorporate turbochargers. This part facilitates the drainage of oil from the turbocharger, ensuring that the lubrication system remains clean and free of contaminants.

Integration with the Filter Head Kit

When integrated with a Filter Head Kit, the Turbocharger Oil Drain Connection plays a significant role in maintaining the quality of the oil circulating within the system. The Filter Head Kit typically includes components designed to filter out impurities from the oil. By efficiently draining oil from the turbocharger, the connection ensures that the oil reaching the filter head is less contaminated, thereby enhancing the effectiveness of the filtration process. This, in turn, contributes to prolonged engine life and optimal performance.

Interaction with Plumbing Components

In the context of Plumbing within the engine system, the Turbocharger Oil Drain Connection is vital for the proper circulation and management of oil. It connects to various plumbing components, such as hoses and pipes, which transport oil to and from the turbocharger. The efficient drainage of oil prevents buildup and ensures that the plumbing system operates under designed parameters, reducing the risk of leaks and maintaining system integrity.

Contribution to Turbocharger Performance

The Turbocharger relies on a consistent supply of clean oil for lubrication and cooling. The Turbocharger Oil Drain Connection ensures that old or contaminated oil is regularly removed from the turbocharger, preventing the accumulation of sludge and other deposits. This regular drainage helps maintain the turbocharger’s efficiency, allowing it to operate at peak performance without the risk of overheating or mechanical failure.

Conclusion

In summary, the Turbocharger Oil Drain Connection (Part 3328643) is a key component in the maintenance and operation of engine systems equipped with turbochargers. Its role in facilitating efficient oil drainage contributes to the overall health and performance of the engine, ensuring that all interconnected components, such as the Filter Head Kit and Plumbing, function optimally.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.