This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

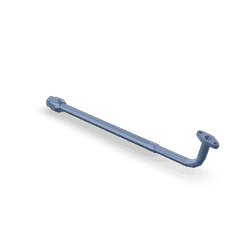

The Turbocharger Oil Drain Connection, identified by Part #3417699, is a component manufactured by Cummins. This part plays a role in the maintenance of heavy-duty truck engines by facilitating the drainage of oil from the turbocharger 1. Cummins, a well-established name in the automotive industry, is recognized for producing reliable and high-quality components designed to enhance the performance and durability of heavy-duty trucks 2.

Basic Concepts

To understand the significance of the Turbocharger Oil Drain Connection, it is important to first grasp the fundamentals of turbochargers and their function within diesel engines. Turbochargers are devices that increase an engine’s efficiency and power output by compressing the air entering the engine, allowing for more fuel to be burned in each cycle. Oil lubrication is vital for the operation of turbochargers, as it reduces friction and wear on moving parts, ensuring smooth and efficient performance 3.

Function of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection is designed to facilitate the drainage of oil from the turbocharger. This process is important for maintaining efficient lubrication and preventing oil contamination within the system. By allowing for the regular removal of used oil, the connection helps to ensure that the turbocharger operates with clean, fresh lubricant, which is important for its efficiency and longevity 4.

Key Features

The Turbocharger Oil Drain Connection is constructed with durability and performance in mind. It is made from high-quality materials that are resistant to the high temperatures and pressures encountered in heavy-duty truck engines. The connection features a secure fitting design that ensures a tight seal, preventing leaks and ensuring the efficient drainage of oil. Additionally, its design allows for easy access during maintenance procedures, enhancing the convenience of use 5.

Benefits

The incorporation of the Turbocharger Oil Drain Connection into a heavy-duty truck engine system offers several advantages. It contributes to improved turbocharger efficiency by ensuring that the component operates with clean lubricant. This, in turn, can lead to extended component lifespan and enhanced engine performance. Regular oil drainage also helps to prevent the buildup of contaminants, which can adversely affect turbocharger operation 6.

Installation and Maintenance

Proper installation of the Turbocharger Oil Drain Connection is important for ensuring optimal performance and longevity. It should be securely fitted according to the manufacturer’s guidelines to prevent leaks and ensure efficient oil drainage. Regular maintenance, including periodic inspection for signs of wear or damage, is recommended to ensure the connection continues to function effectively. Following the manufacturer’s maintenance schedule can help to identify and address any issues before they lead to more significant problems 7.

Troubleshooting

Common issues associated with Turbocharger Oil Drain Connections include leaks and blockages. Diagnostic procedures for identifying these problems may involve visual inspection for signs of oil leakage or the use of diagnostic tools to check for blockages within the system. Recommended solutions for addressing malfunctions or leaks may include tightening connections, replacing worn or damaged parts, or cleaning the system to remove contaminants 8.

Cummins Overview

Cummins Inc. has a long-standing reputation in the automotive industry for manufacturing high-quality components for heavy-duty trucks. Founded with a commitment to innovation and excellence, Cummins has consistently delivered reliable and durable parts that enhance the performance and efficiency of heavy-duty engines. Their Turbocharger Oil Drain Connection is a testament to their dedication to quality and customer satisfaction, offering a solution that contributes to the efficient operation and maintenance of heavy-duty truck engines 9.

Compatibility with Cummins Engines

-

QSM11 Engines: The turbocharger oil drain connection part 3417699 is specifically designed to integrate with the QSM11 engine series. This ensures that the oil drainage system functions optimally, maintaining the health and performance of the turbocharger.

-

CM570 Engines: Similarly, the part is engineered to fit with the CM570 engine series. Its design allows for efficient oil drainage, which is crucial for the longevity and efficiency of the turbocharger 10.

Importance of the Turbocharger Oil Drain Connection

The turbocharger oil drain connection plays a vital role in the engine’s lubrication system. It ensures that the turbocharger is not overfilled with oil, which can lead to inefficient operation and potential damage. By allowing excess oil to drain away, this part helps maintain the correct oil level, ensuring that the turbocharger operates within its optimal parameters. This is crucial for engines that rely on turbochargers to enhance their performance and efficiency 11.

Integration with Turbocharger Plumbing

The turbocharger plumbing system is designed to facilitate the flow of lubrication oil to and from the turbocharger. Part 3417699, the turbocharger oil drain connection, is a key element in this system. It allows for the controlled drainage of oil from the turbocharger, which is essential for several reasons:

-

Oil Circulation Management: The oil drain connection ensures that excess oil is efficiently removed from the turbocharger, preventing oil buildup that could lead to inefficiencies or damage.

-

Maintenance of Oil Levels: By allowing oil to drain back to the sump or oil reservoir, this component helps in maintaining optimal oil levels within the turbocharger, ensuring consistent lubrication.

-

Temperature Regulation: Proper oil drainage aids in temperature regulation within the turbocharger. Excess oil can lead to increased temperatures, which may adversely affect performance and longevity.

-

Contaminant Removal: The drainage process also helps in removing contaminants that may have accumulated in the oil, thereby protecting the turbocharger’s internal components from wear and tear 12.

Interaction with Other Components

The turbocharger oil drain connection works in conjunction with several other components within the engine system:

-

Oil Supply Lines: These lines deliver lubrication oil to the turbocharger. The drain connection ensures that any surplus oil is returned to the system, maintaining a balanced flow.

-

Turbocharger Bearings: The oil drain connection indirectly supports the turbocharger bearings by ensuring that they are not over-lubricated, which could lead to instability and increased friction.

-

Oil Reservoir/Sump: The drained oil is typically returned to the oil reservoir or sump, where it can be recirculated or filtered before being used again.

-

Turbocharger Housing: The connection is usually integrated into the turbocharger housing, allowing for a seamless fit and efficient oil management within the compact space of the turbocharger 13.

Conclusion

In summary, the Turbocharger Oil Drain Connection, part 3417699, is a vital component in the turbocharger plumbing system, ensuring efficient oil management, temperature regulation, and contaminant removal, thereby contributing to the overall performance and longevity of the turbocharger and the engine system as a whole 14.

-

Diesel Engine Care and Repair, Nigel Calder, The McGraw-Hill Companies, 2007

↩ -

Vocational Vehicles and Applications, Michael Hilgers and Wilfried Achenbach, Springer Vieweg, 2021

↩ -

Vocational Vehicles and Applications, Michael Hilgers, Springer Nature, 2023

↩ -

L9 CM2670 L134C, Service Manual (5579952)

↩ -

Diesel Engine Care and Repair, Nigel Calder, The McGraw-Hill Companies, 2007

↩ -

Vocational Vehicles and Applications, Michael Hilgers and Wilfried Achenbach, Springer Vieweg, 2021

↩ -

Vocational Vehicles and Applications, Michael Hilgers, Springer Nature, 2023

↩ -

L9 CM2670 L134C, Service Manual (5579952)

↩ -

Vocational Vehicles and Applications, Michael Hilgers and Wilfried Achenbach, Springer Vieweg, 2021

↩ -

Vocational Vehicles and Applications, Michael Hilgers, Springer Nature, 2023

↩ -

L9 CM2670 L134C, Service Manual (5579952)

↩ -

Diesel Engine Care and Repair, Nigel Calder, The McGraw-Hill Companies, 2007

↩ -

Vocational Vehicles and Applications, Michael Hilgers and Wilfried Achenbach, Springer Vieweg, 2021

↩ -

L9 CM2670 L134C, Service Manual (5579952)

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.