3683071

Turbocharger Oil Drain Connection

Cummins®

AVAILABLE

8 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection, identified by Part #3683071, is a component manufactured by Cummins, a leading name in the commercial truck industry. This part is integral to the operation of heavy-duty truck engines, specifically within the turbocharger system. Its role is to facilitate the circulation and drainage of oil, which is vital for the efficient functioning and longevity of the turbocharger.

Basic Concepts

To understand the significance of the Turbocharger Oil Drain Connection, it is important to first grasp the fundamentals of turbochargers. A turbocharger is a device that increases an engine’s efficiency and power output by forcing extra air into the combustion chamber. This process, known as forced induction, allows more fuel to be burned, resulting in increased power. Oil lubrication is crucial in turbocharger operation as it cools and lubricates the turbocharger’s moving parts, ensuring smooth operation and preventing wear 1.

Function of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection plays a role in the turbocharger system by managing the flow of oil. It is designed to allow oil to circulate through the turbocharger, lubricating and cooling the internal components. After performing its function, the oil is drained back into the engine’s lubrication system. This continuous circulation and drainage are vital for maintaining the turbocharger’s operational efficiency and preventing overheating 2.

Key Features

The Turbocharger Oil Drain Connection is characterized by several key features that enhance its functionality and integration within the turbocharger system. It is typically made from durable materials to withstand the high temperatures and pressures within the engine compartment. The design of the connection ensures a secure fit within the turbocharger assembly, facilitating efficient oil flow. Additionally, it is engineered to be compatible with various turbocharger components, ensuring seamless integration into the system.

Benefits

Utilizing the Turbocharger Oil Drain Connection offers several advantages. It contributes to improved turbocharger efficiency by ensuring consistent oil lubrication and cooling. This, in turn, can lead to an extended lifespan for the turbocharger components, reducing the need for frequent replacements. Furthermore, the efficient operation of the turbocharger, supported by the oil drain connection, can enhance overall engine performance, providing better power output and fuel efficiency.

Installation and Compatibility

Proper installation of the Turbocharger Oil Drain Connection is crucial for its effective operation. It is designed to be compatible with a range of Cummins engine models and turbocharger types, ensuring versatility across different applications. During installation, it is important to follow manufacturer guidelines to ensure a secure and proper fit, which is vital for the component’s function and the overall performance of the turbocharger system.

Maintenance and Troubleshooting

Routine maintenance of the Turbocharger Oil Drain Connection is important to ensure its optimal performance and longevity. This includes regular inspections for signs of wear or damage, and ensuring that the connection remains securely fitted. Common issues may include oil leaks or reduced efficiency, which can often be traced back to improper installation or wear on the connection. Troubleshooting these issues typically involves checking the fit and condition of the connection, and making necessary adjustments or replacements as needed.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a rich history dating back to 1919, Cummins has established a strong reputation in the commercial truck industry for producing reliable and high-performance engines. The company’s product portfolio includes a wide range of engines and components, designed to meet the demanding requirements of heavy-duty applications. Cummins’ commitment to innovation and quality has made it a preferred choice among commercial truck manufacturers and operators.

Turbocharger Oil Drain Connection in Cummins Engines

The Turbocharger Oil Drain Connection, part number 3683071, is a critical component in the maintenance and operation of several Cummins engines. This part is essential for the proper functioning of the turbocharger system by facilitating the drainage of oil from the turbocharger.

ISX CM870

In the ISX CM870 engine, the Turbocharger Oil Drain Connection ensures that the turbocharger is adequately lubricated while also allowing for the removal of excess oil. This helps maintain optimal performance and longevity of the turbocharger, which is crucial for the overall efficiency and reliability of the engine.

Grouping of Engines

The Turbocharger Oil Drain Connection is designed to fit seamlessly with various Cummins engines, ensuring compatibility and ease of maintenance. While the ISX CM870 is specifically mentioned, this part is also compatible with other engines within the Cummins lineup that utilize similar turbocharger systems. This compatibility allows for streamlined maintenance procedures and parts management across different engine models.

By ensuring that the turbocharger oil is properly drained, the Turbocharger Oil Drain Connection helps prevent oil build-up, which can lead to overheating and potential damage to the turbocharger. This part is a testament to Cummins’ commitment to providing reliable and durable components for their engines.

Role of Part 3683071 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection is an essential component in the turbocharger plumbing system, facilitating the efficient management of oil within the turbocharger assembly. This part is designed to connect the turbocharger to the engine’s lubrication system, ensuring that oil is properly drained from the turbocharger after engine operation.

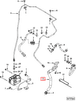

Integration with Turbocharger Plumbing

-

Oil Supply Line: The turbocharger oil drain connection interfaces with the oil supply line, which delivers lubricant to the turbocharger’s bearings and other moving parts. This ensures that the turbocharger receives a consistent flow of oil, reducing friction and wear.

-

Drain Back to Sump: After lubricating the turbocharger, the used oil must be efficiently returned to the engine’s sump or oil pan. The turbocharger oil drain connection plays a key role in this process by providing a secure and leak-proof pathway for the oil to flow back. This helps maintain the oil level in the sump and ensures that the turbocharger does not retain excess oil, which could lead to contamination or overheating.

-

Pressure Relief: In some systems, the turbocharger oil drain connection also aids in pressure relief. By allowing oil to drain back, it helps prevent excessive pressure build-up within the turbocharger, which could otherwise lead to component failure.

-

Thermal Management: Efficient oil drainage is vital for thermal management within the turbocharger. By ensuring that old, heat-soaked oil is promptly removed, the turbocharger oil drain connection helps maintain optimal operating temperatures, enhancing the turbocharger’s longevity and performance.

-

Sealing and Containment: The connection must form a reliable seal to prevent oil leaks, which could cause environmental contamination and pose a fire hazard. It ensures that the oil remains contained within the system, promoting both safety and efficiency.

Conclusion

In summary, the Turbocharger Oil Drain Connection (Part #3683071) is a pivotal element in the turbocharger plumbing system, ensuring proper oil circulation, drainage, and overall system integrity. Its role in maintaining the health and performance of the turbocharger cannot be overstated. Proper installation, maintenance, and understanding of its function are crucial for the efficient operation of heavy-duty truck engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.