This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection (Part #3883660) manufactured by Cummins is a component designed to facilitate the drainage of oil from the turbocharger system in heavy-duty trucks. This part is integral to maintaining the efficiency and longevity of the turbocharger, ensuring that the engine operates within optimal parameters.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger oil drain connections are designed to allow the drainage of lubricating oil from the turbocharger. This process is vital for maintaining the turbocharger’s efficiency and longevity 1. The oil drain connection is part of the larger turbocharger system, which includes the turbine, compressor, and bearing system. Proper drainage of oil helps in reducing the build-up of contaminants and ensures that the turbocharger bearings are adequately lubricated, which is crucial for the smooth operation of the turbocharger 2.

Purpose and Function

The Turbocharger Oil Drain Connection serves the purpose of allowing oil to be drained from the turbocharger system. This function is important for several reasons. Firstly, it helps in removing any contaminants that may have accumulated in the oil, thereby preventing them from circulating within the system. Secondly, it ensures that the turbocharger bearings are not subjected to excessive oil levels, which could lead to inefficient operation. By facilitating the drainage of oil, this component plays a role in maintaining the turbocharger within its optimal operating parameters 3.

Key Features

The Turbocharger Oil Drain Connection is characterized by several key features that enhance its performance and reliability. These include a robust design that ensures durability under high-stress conditions, the use of high-quality materials that resist corrosion and wear, and precise engineering that ensures a secure fit within the turbocharger system. Additionally, the connection may feature unique characteristics such as integrated seals to prevent oil leaks and easy-to-use drainage mechanisms that simplify maintenance procedures.

Benefits

Using the Turbocharger Oil Drain Connection offers several benefits. These include improved turbocharger performance due to efficient oil drainage, enhanced engine efficiency as a result of optimal turbocharger operation, and reduced maintenance requirements thanks to the component’s durable design and easy maintenance features. Additionally, the proper drainage of oil helps in extending the lifespan of the turbocharger by ensuring that its internal components remain well-lubricated and free from contaminants.

Installation Process

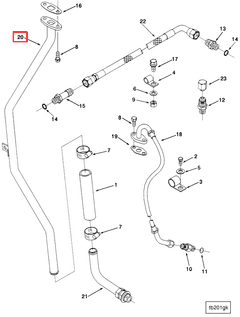

Installing the Turbocharger Oil Drain Connection requires careful attention to detail to ensure a secure and effective fit. The process involves several steps: first, ensuring that the turbocharger system is clean and free from debris; second, aligning the drain connection with the designated port on the turbocharger; third, securing the connection using the appropriate tools to prevent leaks; and finally, testing the connection to ensure that oil drains properly and that there are no leaks. Following these steps helps in achieving a proper installation.

Troubleshooting Common Issues

Common issues that may arise with the Turbocharger Oil Drain Connection include oil leaks, difficulty in draining oil, and corrosion. Troubleshooting these issues involves inspecting the connection for signs of wear or damage, ensuring that it is properly aligned and secured, and cleaning or replacing the connection if necessary. Addressing these problems promptly helps in maintaining the efficiency and reliability of the turbocharger system.

Maintenance Tips

Routine maintenance practices are important for ensuring the longevity and optimal performance of the Turbocharger Oil Drain Connection. These practices include regular inspection of the connection for signs of wear or damage, cleaning the connection to remove any accumulated contaminants, and replacing the connection if it shows signs of significant wear or if oil leaks are detected. Adhering to these maintenance tips helps in preventing issues and ensuring that the turbocharger system operates efficiently.

Cummins Overview

Cummins Inc. is a well-established company with a strong reputation in the automotive industry. Founded in 1919, Cummins has a long history of manufacturing high-quality automotive components, including engines, turbochargers, and related parts. The company is known for its commitment to innovation, quality, and customer satisfaction, making it a trusted name in the industry.

Turbocharger Oil Drain Connection in Cummins Engines

The Turbocharger Oil Drain Connection, part number 3883660, is a critical component in the lubrication system of certain Cummins engines. This part is designed to facilitate the drainage of oil from the turbocharger, ensuring efficient operation and longevity of the turbocharger itself.

Application in M11 CELECT PLUS and M11 MECHANICAL Engines

In the M11 CELECT PLUS and M11 MECHANICAL engines, the Turbocharger Oil Drain Connection plays a pivotal role in maintaining the health of the turbocharger. The M11 CELECT PLUS engine, known for its advanced electronic controls and fuel efficiency, relies on this part to manage oil flow effectively. Similarly, the M11 MECHANICAL engine, which emphasizes robust mechanical design and reliability, also benefits from the precise functionality of this component.

The Turbocharger Oil Drain Connection is strategically positioned within the engine’s oil system. It ensures that any excess oil, which may accumulate due to the turbocharger’s operation, is efficiently drained back into the engine’s oil sump. This prevents oil from entering the turbocharger’s bearings and other sensitive areas, which could lead to overheating and potential failure.

Importance of Proper Installation

Proper installation of the Turbocharger Oil Drain Connection is crucial. It must be securely attached to the turbocharger and the engine’s oil system to prevent leaks. Any failure in this connection can lead to oil starvation in the turbocharger, causing it to overheat and potentially fail. Conversely, a leak can result in oil contamination within the engine, leading to a host of other issues.

Compatibility and Maintenance

The Turbocharger Oil Drain Connection is designed to be compatible with both the M11 CELECT PLUS and M11 MECHANICAL engines. Regular maintenance checks should include inspecting this part for any signs of wear, corrosion, or leaks. Ensuring that the connection is tight and free from obstructions is essential for maintaining the engine’s performance and reliability.

Role of Part 3883660 Turbocharger Oil Drain Connection in Engine Systems

The part 3883660 Turbocharger Oil Drain Connection is an essential component in the maintenance and operation of turbocharged engine systems. This part facilitates the drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters.

Integration with Turbocharger

In the context of the turbocharger, the oil drain connection is positioned to allow for the periodic removal of oil that has been used to lubricate the turbocharger’s bearings and other moving parts. This process is vital for maintaining the integrity of the lubrication system, as it prevents the buildup of contaminants and degraded oil, which can lead to increased wear and potential failure of the turbocharger.

Interaction with Plumbing

The oil drain connection also interfaces with the engine’s plumbing system. It is typically connected to a drain line that leads to an oil collection point, such as an oil pan or a dedicated drain tank. This setup ensures that the drained oil is safely collected and can be disposed of or recycled according to environmental regulations. The plumbing must be designed to handle the flow of oil without leaks, which requires careful consideration of pipe diameters, connection types, and the routing of the drain line to avoid interference with other engine components.

Maintenance and Operational Efficiency

Regular use of the oil drain connection is part of routine maintenance procedures. By facilitating the easy removal of oil, it allows mechanics to inspect the condition of the oil, which can provide insights into the health of the turbocharger. Clean, clear oil typically indicates good turbocharger condition, whereas discolored or contaminated oil may signal issues that require further investigation.

Conclusion

In summary, the Turbocharger Oil Drain Connection plays a significant role in the turbocharger and plumbing systems by ensuring efficient oil management, contributing to the longevity and performance of the turbocharger, and simplifying maintenance procedures. Proper installation, regular maintenance, and understanding its role within the engine system are key to leveraging the full potential of this component.

-

SAE International’s Dictionary for Automotive Engineers, John F Kershaw, SAE International, 2023

↩ -

Fundamentals of Automotive and Engine Technology: Standard Drives, Hybrid Drives, Brakes, Safety Systems, Konrad Reif, Springer Vieweg, 2014

↩ -

Mobile Equipment Hydraulics A Systems and Troubleshooting Approach, Ben Watson, Cengage Learning, 2011

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.