3916348

Turbocharger Oil Drain Connection

Cummins®

AVAILABLE

2 are currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection (3916348) by Cummins is a specialized component designed for use in heavy-duty truck engines. Its purpose is to facilitate the drainage of oil from the turbocharger, ensuring that the turbocharger operates efficiently and remains in optimal condition. This component plays a role in the turbocharger system by allowing for the periodic removal of oil, which is crucial for maintaining the turbocharger’s health and performance 1.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger oil drain connections operate on the principle of allowing excess oil, which lubricates the turbocharger’s moving parts, to be drained away. This process is vital for preventing oil buildup, which can lead to decreased efficiency and potential damage to the turbocharger. By enabling the removal of used oil, these connections help maintain the cleanliness and effectiveness of the turbocharger’s lubrication system 2.

Purpose and Function

The Turbocharger Oil Drain Connection is designed to contribute to the efficient operation of the turbocharger in heavy-duty truck engines. It allows for the scheduled drainage of oil, which helps in reducing the risk of oil contamination and ensures that the turbocharger’s moving parts are adequately lubricated. This, in turn, supports the overall performance and longevity of the engine by maintaining the turbocharger in optimal working condition 3.

Key Features

The Turbocharger Oil Drain Connection is characterized by its robust design and the use of high-quality materials. These features enhance its performance and durability, ensuring it can withstand the demanding conditions of heavy-duty truck engines. The connection is engineered to provide a secure and reliable means of draining oil, with attention to detail in its construction to ensure compatibility and ease of use.

Benefits

Utilizing the Turbocharger Oil Drain Connection offers several advantages. It contributes to improved turbocharger longevity by facilitating regular oil changes, which help prevent buildup and contamination. Additionally, it enhances engine efficiency by ensuring that the turbocharger operates under optimal lubrication conditions. Furthermore, the use of this component can lead to reduced maintenance requirements, as it helps maintain the turbocharger’s performance over time.

Installation and Compatibility

Proper installation of the Turbocharger Oil Drain Connection is important for ensuring its effectiveness. It is designed to be compatible with specific Cummins engine models and turbocharger types, ensuring a seamless integration into the engine system. Following the manufacturer’s guidelines for installation is recommended to achieve the best results and ensure the component functions as intended.

Maintenance and Troubleshooting

Routine maintenance of the Turbocharger Oil Drain Connection is important for its optimal performance. This includes regular checks for any signs of wear or damage and ensuring that the connection is securely in place. Troubleshooting common issues, such as leaks or difficulty in draining oil, may involve inspecting the connection for blockages or ensuring that it is correctly installed. Addressing these issues promptly can help maintain the efficiency and reliability of the turbocharger.

Cummins Overview

Cummins Inc. is a leading manufacturer in the automotive industry, known for its commitment to quality and innovation. With a rich history of producing reliable and high-performance engine components, Cummins has established a reputation for excellence. The company’s product offerings include a wide range of engine parts and systems designed to meet the demanding requirements of heavy-duty applications. Cummins’ dedication to advancing technology and improving engine efficiency is evident in its design and manufacturing processes.

Turbocharger Oil Drain Connection (Part 3916348) Compatibility with Cummins Engines

The Turbocharger Oil Drain Connection, part number 3916348, manufactured by Cummins, is a critical component for maintaining the health and efficiency of the turbocharger in various Cummins engine models. This part ensures that oil is properly drained from the turbocharger, preventing oil accumulation that could lead to bearing failure and other mechanical issues.

Compatibility with Specific Engine Models

-

6B5.9: The part 3916348 is designed to fit seamlessly with the 6B5.9 engine, ensuring efficient oil drainage from the turbocharger.

-

B5.9 G, B5.9 GAS PLUS CM556: These engines also benefit from the precise fit and functionality of the 3916348 turbocharger oil drain connection, facilitating optimal oil management.

-

ISB CM550, QSB5.9 30 CM550, QSB5.9 44 CM550: These models are equipped with the 3916348 part to maintain the integrity of the turbocharger oil system, ensuring that oil is drained effectively.

-

ISB5.9 CM2880 B110, ISB5.9G CM2180: The turbocharger oil drain connection part 3916348 is compatible with these engines, providing a reliable solution for oil drainage.

-

QSB6.7 CM850 (CM2850): This engine model also utilizes the 3916348 part to ensure that the turbocharger oil system operates efficiently, preventing potential oil-related issues.

The turbocharger oil drain connection part 3916348 is engineered to fit a range of Cummins engines, ensuring that oil is effectively drained from the turbocharger. This part is essential for maintaining the longevity and performance of the turbocharger, thereby contributing to the overall reliability of the engine.

Understanding the Role of Part 3916348 Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection is an essential component in the maintenance and operation of turbocharger systems within various engine setups. This component is specifically designed to facilitate the drainage of oil from the turbocharger, ensuring that the system remains clean and operates efficiently.

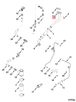

Integration with Turbocharger Plumbing

The Turbocharger Oil Drain Connection is seamlessly integrated into the turbocharger plumbing system. This integration allows for the efficient routing of oil away from the turbocharger, preventing oil buildup which could lead to performance issues. The connection point is typically located at a low point in the system to ensure that all oil can be effectively drained.

Interaction with Turbocharger Oil System

Within the turbocharger oil system, the Drain Connection plays a key role in maintaining oil quality. By providing a dedicated path for oil drainage, it helps in reducing contamination and ensuring that the oil circulating within the turbocharger remains clean. This is particularly important in high-performance engines where oil cleanliness directly impacts turbocharger longevity and efficiency.

Relationship with Water Outlet and Cooling System

In engines where the turbocharger is cooled using a water outlet system, the Turbocharger Oil Drain Connection works in conjunction with these components to maintain optimal operating conditions. The efficient drainage of oil ensures that the cooling system is not compromised by oil contamination, which could otherwise lead to overheating and reduced performance.

Role in Overall Engine Maintenance

From a maintenance perspective, the Turbocharger Oil Drain Connection simplifies the process of oil changes and system inspections. By providing a straightforward method for oil drainage, it allows mechanics to perform routine maintenance more efficiently, thereby contributing to the overall reliability and performance of the engine system.

Conclusion

In summary, the Turbocharger Oil Drain Connection (3916348) is a vital component in the turbocharger and engine systems. Its proper integration and function are essential for maintaining system cleanliness, ensuring efficient operation, and simplifying maintenance procedures.

-

Hu, H., Smaling, R., & Baseley, S. (2014). Heavy-Duty Wheeled Vehicles. SAE International.

↩ -

Goodnight, N., & VanGelder, K. (2019). Automotive Braking Systems CDX Master Automotive Technician Series. Jones Bartlett Learning.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.