This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

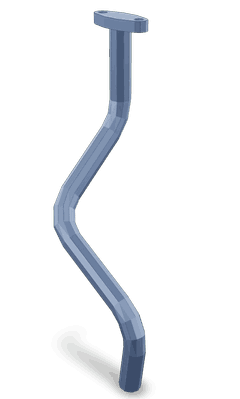

The Turbocharger Oil Drain Connection, identified by Part #3917936, is a component manufactured by Cummins, a well-established name in the automotive industry. This part is integral to the operation of heavy-duty truck engines, facilitating the efficient management of oil within the turbocharger system. Understanding its role and functionality is key to maintaining engine performance and longevity.

Basic Concepts of Turbocharger Oil Drain Connection

Turbochargers are devices that increase an engine’s power output by forcing extra air into the combustion chamber. This process, known as forced induction, allows more fuel to be burned, resulting in increased power. The turbocharger itself is lubricated by engine oil, which is circulated through the turbocharger’s bearings and other moving parts. The oil drain connection plays a specific role in this system by allowing the used oil to be returned to the engine’s lubrication system for recirculation or disposal, thus maintaining the turbocharger’s efficiency and the engine’s overall performance 1.

Purpose of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection is designed to facilitate the drainage of oil from the turbocharger. This process is vital for maintaining the turbocharger’s efficiency, as it ensures that the turbocharger bearings and other moving parts are adequately lubricated without the buildup of excess oil. By efficiently managing oil levels, this component helps in preserving the turbocharger’s performance and contributes to the engine’s reliability and power output 2.

Key Features

The Turbocharger Oil Drain Connection is characterized by its robust design and high-quality materials, which are chosen to withstand the harsh conditions within a heavy-duty truck engine. Its design ensures a secure connection to the turbocharger, minimizing the risk of leaks. Additionally, the material used in its construction is resistant to corrosion and wear, enhancing its durability and performance over time 3.

Benefits

Utilizing the Turbocharger Oil Drain Connection offers several advantages. It contributes to improved engine efficiency by ensuring optimal turbocharger lubrication. This component also reduces maintenance requirements by facilitating easy oil drainage, which helps prevent oil buildup and associated issues. Furthermore, it enhances the overall performance of the engine by maintaining the turbocharger’s efficiency, leading to better power output and fuel economy 4.

Installation Process

Installing the Turbocharger Oil Drain Connection requires careful attention to detail to ensure a proper fit and function. The process involves disconnecting the old drain connection, cleaning the area around the turbocharger, and then securely attaching the new connection. It is important to use the appropriate tools and follow safety precautions, such as wearing protective gear and ensuring the engine is cool before beginning work. A torque wrench may be necessary to achieve the correct tightening specifications for the connection.

Troubleshooting

Common issues with the Turbocharger Oil Drain Connection may include leaks or blockages, which can affect turbocharger performance. Diagnosing these problems involves inspecting the connection for signs of wear, corrosion, or damage. Solutions may range from cleaning the connection and ensuring it is properly seated to replacing the component if it is found to be faulty. Regular inspections can help identify potential issues before they lead to more significant problems.

Maintenance Tips

To ensure the optimal performance and longevity of the Turbocharger Oil Drain Connection, regular maintenance is recommended. This includes inspecting the connection for signs of wear or damage during routine engine maintenance checks. Cleaning the area around the connection can also help prevent the buildup of dirt and debris, which may affect its function. Following the manufacturer’s guidelines for maintenance intervals and procedures will help maintain the efficiency and reliability of the turbocharger and engine.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a strong reputation in the automotive industry, Cummins is committed to producing high-quality engine components that meet the demanding requirements of heavy-duty applications. Their focus on innovation, quality, and customer satisfaction has established them as a trusted name in the production of engine parts, including the Turbocharger Oil Drain Connection.

Compatibility with Cummins Engines

-

6C8.3 Series: The Turbocharger Oil Drain Connection is specifically engineered to fit within the 6C8.3 engine series. This series is known for its robust performance and reliability, often utilized in heavy-duty applications. The part ensures that oil is properly drained from the turbocharger, preventing oil accumulation that could lead to overheating and mechanical failure.

-

Other Cummins Engines: While the primary focus here is on the 6C8.3 series, it is important to note that similar turbocharger oil drain connections are used across various Cummins engine models. These parts are designed to maintain compatibility with the specific lubrication requirements of each engine type, ensuring optimal performance and longevity.

Role of Part 3917936 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection is an essential component in the maintenance and operation of turbocharger systems within various engine setups. This component facilitates the necessary drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters.

Integration with Turbocharger

In the context of a turbocharger, the oil drain connection is positioned to allow the used oil, which has lubricated the turbocharger’s moving parts, to be efficiently removed. This process is vital for maintaining the cleanliness and viscosity of the oil, which directly impacts the turbocharger’s performance and longevity. The connection point is typically located at the lower part of the turbocharger housing, ensuring that oil can gravity-feed out of the system.

Interaction with Plumbing Systems

The Turbocharger Oil Drain Connection interfaces with the engine’s plumbing system, which includes oil lines and drainage pathways. This integration ensures that the drained oil is directed away from the turbocharger and into the appropriate collection or recycling system. The design of the connection must accommodate the specific flow rates and pressures associated with the engine’s oil system to prevent leaks and ensure smooth operation.

Maintenance and Operational Benefits

By incorporating the Turbocharger Oil Drain Connection, engineers and mechanics can perform routine maintenance more effectively. Regular drainage of oil helps in identifying potential issues such as contamination or abnormal wear patterns early on. This proactive approach to maintenance can lead to extended turbocharger life and improved engine reliability.

Conclusion

In summary, the Turbocharger Oil Drain Connection (part 3917936) plays a significant role in the efficient operation and maintenance of turbocharger systems. Its proper integration with both the turbocharger and the engine’s plumbing system ensures that the turbocharger remains well-lubricated and functions optimally. Regular maintenance and timely replacement of this part are crucial for the longevity and performance of heavy-duty engines.

-

Eret, Angelina. Dynamic and Fatigue Assessment of Heavy-Duty Engine Valves. Springer Nature, 2024.

↩ -

Randall, Martynn. Haynes Manual on Diesel Engines. Haynes Publishing, 2015.

↩ -

Giles, Tim. Automotive Engines Diagnosis Repair and Rebuilding. Cengage Learning, 2019.

↩ -

Rajamani, Rajesh. Vehicle Dynamics and Control. Springer, 2005.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.