This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

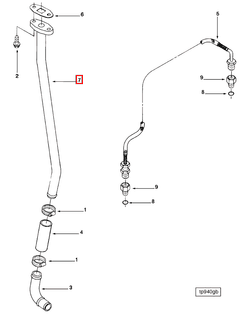

The Turbocharger Oil Drain Connection, identified by Part #3918583, is a component manufactured by Cummins, a leading name in the automotive and heavy-duty truck industries. This part plays a role in the maintenance and operation of heavy-duty truck engines, particularly in the management of oil within the turbocharger system.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger oil drain connections are integral to the turbocharger system, facilitating the efficient management of oil that lubricates and cools the turbocharger. Proper oil management is vital for maintaining the efficiency and longevity of the turbocharger. The oil drain connection allows for the removal of used oil, which can become contaminated with soot and other particles, ensuring that fresh, clean oil circulates through the system. This process helps in reducing wear and tear on the turbocharger components, thereby enhancing overall engine performance 1.

Purpose and Role in Truck Operation

The Turbocharger Oil Drain Connection is specifically designed to serve a function in heavy-duty truck engines. It enables the periodic draining of oil from the turbocharger, which is necessary to remove contaminants and ensure that the turbocharger operates efficiently. By facilitating the drainage of used oil, this component contributes to the sustained performance and reliability of both the turbocharger and the engine. Regular oil changes help prevent buildup of harmful deposits, which can lead to decreased efficiency and potential damage to the turbocharger 2.

Key Features

The Turbocharger Oil Drain Connection is characterized by several key features that enhance its functionality and durability. It is constructed from high-quality materials that are resistant to the high temperatures and pressures encountered within the turbocharger system. The design of the connection ensures a secure fit, preventing leaks and ensuring that oil is effectively drained from the system. Additionally, the connection is engineered to be compatible with a variety of turbocharger models, making it a versatile component for use in different heavy-duty truck applications 3.

Benefits

The advantages of using the Turbocharger Oil Drain Connection include improved oil management within the turbocharger system, leading to enhanced turbocharger performance. By ensuring that clean oil circulates through the system, this component helps maintain the efficiency of the turbocharger and extends its operational life. Furthermore, the use of this connection can result in potential cost savings, as it reduces the frequency of maintenance requirements and extends the intervals between oil changes. This not only minimizes downtime but also contributes to the overall cost-effectiveness of maintaining heavy-duty truck engines.

Troubleshooting and Maintenance Suggestions

To ensure the optimal performance and longevity of the Turbocharger Oil Drain Connection, it is important to be aware of common issues and their solutions. Regular inspection of the connection for signs of wear, leaks, or contamination is recommended. If leaks are detected, it may be necessary to replace the gasket or the connection itself to prevent oil loss and ensure the turbocharger operates efficiently. Additionally, adhering to the manufacturer’s recommended maintenance schedule for oil changes and system inspections can help identify potential issues before they lead to more significant problems.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, emissions solutions, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and customer satisfaction within the automotive and heavy-duty truck industries. The company’s commitment to excellence is evident in its product offerings, which are designed to meet the demanding requirements of modern engines and contribute to the efficiency, reliability, and performance of vehicles worldwide.

Turbocharger Oil Drain Connection for Cummins Engines

The turbocharger oil drain connection, part number 3918583, is a component in the lubrication system of several Cummins diesel engines. This part is designed to facilitate the drainage of oil from the turbocharger, ensuring that the turbocharger operates efficiently and reliably.

Compatibility with Cummins Engines

-

6B5.9: The turbocharger oil drain connection is compatible with the 6B5.9 engine, ensuring that the turbocharger’s lubrication system is properly maintained.

-

ISB CM550: This part fits seamlessly with the ISB CM550 engine, providing a reliable method for oil drainage from the turbocharger.

-

QSB5.9 44 CM550: The turbocharger oil drain connection is also suitable for the QSB5.9 44 CM550 engine, ensuring that the turbocharger’s lubrication system is properly maintained.

These engines, while differing in their specific applications and configurations, share a common requirement for efficient turbocharger lubrication. The turbocharger oil drain connection, part number 3918583, is engineered to meet these requirements, ensuring that the turbocharger operates smoothly and efficiently across various engine models.

Role of Part 3918583 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection, identified as part 3918583, is a component in the maintenance and operation of turbocharged engine systems. This part is specifically designed to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and the turbocharger operates within optimal parameters.

Integration with Turbocharger

In turbocharged engines, the turbocharger is a high-speed component that requires consistent lubrication to reduce friction and wear. The Turbocharger Oil Drain Connection is strategically positioned to allow for the periodic removal of oil that has circulated through the turbocharger. This process helps in maintaining the cleanliness and viscosity of the oil, which is essential for the turbocharger’s bearings and other moving parts.

Interaction with Plumbing Systems

The Turbocharger Oil Drain Connection interfaces with the engine’s plumbing system, which includes oil lines and filters. This connection point is vital for the overall oil management within the engine. It ensures that used oil can be efficiently drained away from the turbocharger, preventing contamination and ensuring that fresh, clean oil is always available for lubrication.

The integration with the plumbing system also allows for easier maintenance and inspection. Engineers and mechanics can quickly connect drainage tools to the Turbocharger Oil Drain Connection, facilitating routine oil changes and inspections without the need for extensive disassembly of the engine components.

Importance in Maintenance Routines

Regular use of the Turbocharger Oil Drain Connection is a part of maintenance routines for turbocharged engines. By allowing for the straightforward drainage of oil, this component helps in prolonging the life of the turbocharger and enhancing the overall performance and reliability of the engine. It is a simple yet effective way to ensure that the turbocharger remains in peak condition, contributing to the engine’s efficiency and power output.

Conclusion

The Turbocharger Oil Drain Connection, part number 3918583, is a vital component in the maintenance and operation of heavy-duty truck engines. By facilitating efficient oil management within the turbocharger system, this part contributes to the sustained performance and reliability of both the turbocharger and the engine. Regular maintenance and adherence to manufacturer guidelines are essential for maximizing the benefits of this component, ensuring optimal engine performance and longevity.

-

Technologies and Approaches to Reducing the Fuel Consumption of Medium and Heavy-Duty Vehicles, Andrew Brown Jr, National Academy of Sciences, 2010

↩ -

Heavy Duty Truck Systems Fifth Edition, Sean Bennett, Ian Andrew Norman, Delmar Cengage Learning, 2011

↩ -

A Practical Approach to Motor Vehicle Engineering and Maintenance, Third Edition, Allan Bonnick and Derek Newbold, Elsevier Ltd, 2011

↩

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.