This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Turbocharger Oil Drain Connection, identified by part number 3922096, is a critical component in the turbocharger system of heavy-duty truck engines. This connection is essential for maintaining the efficiency and reliability of the turbocharger, which supports the overall performance of the engine. By facilitating the periodic removal of used oil, it ensures that the turbocharger operates with optimal lubrication, contributing to the longevity and performance of the engine.

Basic Concepts of Turbocharger Oil Drain Connection

Turbochargers operate by compressing the air entering the engine, allowing for more fuel to be burned and thus increasing power output. A key aspect of turbocharger functionality is the lubrication system, which reduces friction and wear on moving parts. The oil drain connection plays a role in this system by allowing for the removal of used oil. This process ensures that fresh oil is circulated through the turbocharger, maintaining lubrication efficiency and reducing the accumulation of contaminants that can impair performance 1.

Purpose and Function

The 3922096 Turbocharger Oil Drain Connection is designed to aid in the maintenance of the turbocharger. It allows for the periodic draining of oil, which is crucial for reducing contaminants and maintaining the efficiency of the lubrication system. By ensuring that clean oil is consistently circulated, this component helps in preserving the turbocharger’s moving parts, thereby supporting the engine’s performance and reliability.

Key Features

The design and construction of the 3922096 Turbocharger Oil Drain Connection incorporate several features that enhance its functionality and durability. Constructed from high-quality materials, this connection is built to withstand the demanding conditions within a turbocharger environment. Its design includes a secure connection type that ensures a reliable seal, preventing oil leaks and maintaining system integrity. Unique design elements may also include anti-corrosion coatings and reinforced structures to further enhance durability.

Benefits

The advantages provided by the 3922096 Turbocharger Oil Drain Connection are manifold. By facilitating the efficient draining and replacement of oil, it contributes to improved turbocharger longevity. This, in turn, supports enhanced engine performance, as a well-maintained turbocharger can operate more efficiently. Additionally, the design of this connection simplifies maintenance procedures, making it easier for technicians to perform necessary oil changes and inspections 2.

Troubleshooting and Maintenance

Common issues that may arise with the Turbocharger Oil Drain Connection include leaks and blockages. Troubleshooting these issues involves inspecting the connection for signs of wear or damage and ensuring that it is properly sealed. Maintenance tips for ensuring the longevity and efficient operation of the connection include regular inspection for leaks, cleaning the connection area to prevent debris accumulation, and following manufacturer guidelines for oil change intervals. These practices help in maintaining the integrity of the turbocharger lubrication system 3.

About Cummins

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history rooted in diesel engine manufacturing, Cummins has established itself as a pioneer in the automotive industry, known for its commitment to innovation, quality, and customer satisfaction. The company’s expertise in engine technology is reflected in its wide range of products, including the Turbocharger Oil Drain Connection, which is designed to meet the demanding requirements of heavy-duty truck engines.

Application in Cummins Engines

The turbocharger oil drain connection part 3922096 is compatible with several Cummins engine models. It is specifically engineered to fit seamlessly within the engine architecture, ensuring that oil is drained efficiently and does not accumulate within the turbocharger.

Engine Group: 6B5.9

In the 6B5.9 engine series, the turbocharger oil drain connection part 3922096 plays a vital role in maintaining the health of the turbocharger. This part is designed to interface with the specific design and layout of the 6B5.9 engine, ensuring that oil is drained effectively and does not interfere with the turbocharger’s operation.

The 6B5.9 engine is known for its robust performance and reliability, and the turbocharger oil drain connection part 3922096 is a testament to Cummins’ commitment to providing high-quality components that enhance engine performance. By ensuring that oil is properly drained, this part helps to prevent oil-related issues that could otherwise lead to turbocharger failure or reduced engine efficiency.

The seamless integration of the turbocharger oil drain connection part 3922096 into the 6B5.9 engine ensures that the turbocharger operates at peak efficiency, contributing to the overall reliability and performance of the engine. This part is a critical component in the maintenance and upkeep of the 6B5.9 engine, ensuring that it continues to deliver the power and efficiency that Cummins engines are known for.

Role of Part 3922096 Turbocharger Oil Drain Connection in Engine Systems

The 3922096 Turbocharger Oil Drain Connection is an essential component in the efficient operation of turbocharged engine systems. This part facilitates the drainage of oil from the turbocharger, ensuring that the lubrication system remains effective and that the turbocharger operates within optimal parameters.

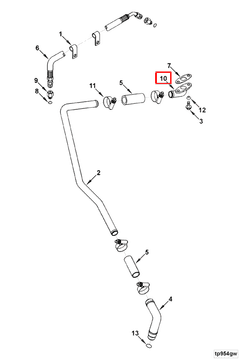

Integration with Turbocharger

In the context of the turbocharger, the 3922096 connection is designed to interface directly with the turbocharger’s oil system. It allows for the periodic removal of oil that has been used to lubricate the turbocharger’s bearings and other moving parts. This drainage is vital for maintaining the cleanliness and viscosity of the oil, which in turn ensures the longevity and performance of the turbocharger.

Interaction with Plumbing

The Turbocharger Oil Drain Connection also plays a significant role in the engine’s plumbing system. It is typically connected to a network of hoses and pipes that transport oil to and from the turbocharger. The connection point provided by part 3922096 allows for the safe and controlled release of oil, which can then be routed back to the sump or another designated collection point for recycling or disposal.

Ensuring System Integrity

By providing a reliable drainage point, the 3922096 connection helps to maintain the integrity of the entire lubrication system. It prevents oil buildup within the turbocharger, which could lead to increased temperatures, reduced efficiency, and potential damage to the turbocharger components. The consistent drainage facilitated by this part ensures that the oil system operates within designed specifications, contributing to the overall reliability and performance of the engine 4.

Conclusion

The 3922096 Turbocharger Oil Drain Connection is a vital component in the maintenance and operation of turbocharged engine systems. By facilitating the efficient drainage of oil, it ensures that the turbocharger remains well-lubricated and operates at peak efficiency. This, in turn, supports the overall performance and reliability of the engine, making it an indispensable part of Cummins’ engine technology.

-

Ling, Frederick F. The Automotive Body. Springer Science, 2011.

↩ -

Caines, Arthur J, Roger F Haycock, and John E Hillier. Automotive Lubricants Reference Book. SAE International, 2004.

↩ -

Genta, Giancarlo, and Lorenzo Morello. The Automotive Chassis Volume 1 Components Design Mechanical Engineering Series 2nd Edition. Springer, 2019.

↩ -

Lakshminarayanan, P. A., and Avinash Kumar Agarwal. Design and Development of Heavy Duty Diesel Engines: A Handbook. Springer, 2019.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.