This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

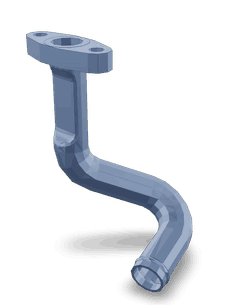

The Turbocharger Oil Drain Connection, identified by part number 3925757, is a component manufactured by Cummins, a well-established name in the automotive industry. This part is integral to the operation of heavy-duty truck engines, facilitating the efficient drainage of oil from the turbocharger. Cummins, known for its commitment to quality and performance, ensures that this component meets the rigorous demands of commercial vehicle applications.

Basic Concepts of Turbocharger Oil Drain Connection

To understand the significance of the Turbocharger Oil Drain Connection, it is important to grasp the fundamental principles behind turbochargers. Turbochargers are devices that increase an engine’s efficiency and power output by compressing the air entering the engine. This compressed air allows for more fuel to be burned, resulting in greater power. The oil drain connection plays a role in maintaining turbocharger efficiency and longevity by ensuring that excess oil, which can accumulate during operation, is properly drained away. This helps prevent oil buildup, which can lead to decreased performance and potential damage to the turbocharger 1.

Purpose and Function of the 3925757 Turbocharger Oil Drain Connection

The 3925757 Turbocharger Oil Drain Connection is designed to facilitate the drainage of oil from the turbocharger. During operation, oil is used to lubricate the turbocharger’s moving parts. Over time, this oil can accumulate and, if not properly drained, may lead to inefficiencies and potential damage. The oil drain connection provides a pathway for this oil to be safely and efficiently removed, ensuring that the turbocharger operates within optimal parameters. By maintaining proper oil levels and preventing buildup, this component contributes to the overall performance and reliability of the engine 2.

Key Features

The 3925757 Turbocharger Oil Drain Connection is characterized by several key features that enhance its performance and durability. It is constructed from high-quality materials that are resistant to the high temperatures and pressures encountered in heavy-duty truck engines. The design incorporates precise engineering to ensure a secure fit and effective drainage. Additionally, the connection may feature unique attributes such as anti-corrosion coatings or specialized threading to further improve its functionality and longevity in demanding environments 3.

Benefits of Using the 3925757 Turbocharger Oil Drain Connection

Incorporating the 3925757 Turbocharger Oil Drain Connection into a truck’s engine system offers several advantages. By ensuring efficient oil drainage, this component helps maintain turbocharger efficiency, which in turn contributes to improved engine performance. Enhanced reliability is another benefit, as proper oil management reduces the risk of turbocharger failure. Additionally, by extending the lifespan of the turbocharger through effective maintenance, this part can lead to potential cost savings for fleet operators 4.

Installation and Compatibility

Proper installation of the 3925757 Turbocharger Oil Drain Connection is vital to ensure its effectiveness and the overall performance of the engine. Installation procedures should follow manufacturer guidelines to ensure a secure and proper fit. It is important to verify compatibility with the specific truck model and engine type to ensure optimal performance and avoid potential issues. Cummins provides detailed instructions and recommendations to assist in the installation process, ensuring that the component is correctly integrated into the engine system 5.

Maintenance and Troubleshooting

Routine maintenance practices are recommended to ensure the optimal performance of the 3925757 Turbocharger Oil Drain Connection. Regular inspections should be conducted to check for any signs of wear, damage, or oil leakage. Cleaning the connection and surrounding areas can help prevent buildup and ensure efficient drainage. In the event of common issues such as oil leaks or decreased performance, troubleshooting steps may include checking for proper installation, inspecting for damage, and ensuring that the connection is securely fitted. Addressing these issues promptly can help maintain the efficiency and reliability of the turbocharger and engine system.

Cummins: A Brief Overview

Cummins Inc. is a globally recognized leader in the design, manufacture, and distribution of engines and related technologies. With a history spanning over a century, Cummins has established a reputation for producing high-quality components that meet the demanding requirements of commercial vehicles. The company’s commitment to innovation, quality, and customer satisfaction is evident in its extensive range of products, including the 3925757 Turbocharger Oil Drain Connection. Cummins continues to be a trusted partner for fleet operators, providing reliable and efficient solutions for heavy-duty truck engines.

Conclusion

The Turbocharger Oil Drain Connection part number 3925757, manufactured by Cummins, is a critical component in the engine’s lubrication system. This part ensures that oil is efficiently drained from the turbocharger, maintaining optimal performance and longevity of the turbocharger itself. In the context of the 6C8.3 engine, the Turbocharger Oil Drain Connection 3925757 is designed to integrate seamlessly with the engine’s turbocharger system. This part is engineered to meet the specific demands of the 6C8.3 engine, ensuring that oil is properly managed and drained to prevent any potential damage or overheating of the turbocharger.

For engines within the same engine family or group, the Turbocharger Oil Drain Connection 3925757 is designed to be compatible, ensuring a standardized approach to turbocharger oil management across different engine models. This compatibility allows for ease of maintenance and repair, as the same part can be used across multiple engine types, reducing the need for specialized parts and inventory.

This part is essential for maintaining the efficiency and reliability of the turbocharger, ensuring that the engine operates at peak performance levels.

-

Bonneau, D., Fatu, A., & Souchet, D. (2014). Internal Combustion Engine Bearings Lubrication in Hydrodynamic Bearings. Wiley-ISTE.

↩ -

Boyce, M. P. (2002). Gas Turbine Engineering Handbook, Second Edition. Gulf Professional Publishing.

↩ -

Dixon, J. C. (1996). Tyres Suspension and Handling Second Edition. SAE International.

↩ -

Happian-Smith, J. (2002). An Introduction to Modern Vehicle Design. Butterworth-Heinemann.

↩ -

Cummins Inc. (n.d.). Operation and Maintenance Manual for ISBe2 and ISBe3 CM850, Bulletin Number 4021680.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.