3926842

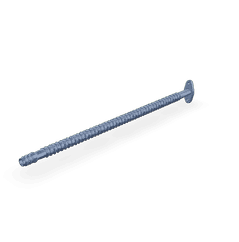

Turbocharger Oil Drain Connection

Cummins®

IN STOCK

6 are currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection, part number 3926842, is a component designed by Cummins, a leading manufacturer in the diesel engine and component industry. This part is integral to the operation of heavy-duty trucks, specifically within the turbocharger system. Cummins is renowned for its commitment to innovation and quality, providing reliable and efficient solutions for the automotive industry.

Basic Concepts of Turbocharger Oil Drain Connection

Turbochargers are devices that increase an engine’s efficiency and power output by forcing extra air into the combustion chamber. This process, known as forced induction, allows more fuel to be burned, resulting in increased performance 1. The turbocharger oil drain connection is a critical component within this system. It facilitates the drainage of oil used to lubricate the turbocharger’s moving parts, ensuring smooth operation and preventing buildup that could lead to inefficiencies or damage.

Purpose and Function

The Turbocharger Oil Drain Connection plays a role in the turbocharger system by allowing for the periodic removal of oil. This process is vital for maintaining the turbocharger’s performance and longevity. By ensuring that old or contaminated oil is regularly drained, the connection helps to prevent the accumulation of deposits and maintains the efficiency of the lubrication system. This, in turn, supports the turbocharger’s ability to operate at optimal levels, contributing to the overall performance and reliability of the engine 2.

Key Features

The Turbocharger Oil Drain Connection is designed with several key features that enhance its functionality. These include a robust construction that ensures durability under the high-stress conditions of heavy-duty truck operation. The connection is made from high-quality materials that resist corrosion and wear, ensuring a long service life. Additionally, its design allows for easy access and straightforward drainage procedures, minimizing downtime during maintenance.

Benefits

Using the Turbocharger Oil Drain Connection offers several benefits. It contributes to improved engine efficiency by ensuring that the turbocharger operates with optimal lubrication. This can lead to reduced maintenance requirements, as clean oil circulation helps prevent wear and tear on turbocharger components. Furthermore, the connection enhances overall performance by supporting the turbocharger’s ability to deliver increased air flow to the engine, resulting in better power output and fuel efficiency 3.

Installation and Compatibility

Proper installation of the Turbocharger Oil Drain Connection is crucial for its effective operation. It is designed to be compatible with various Cummins engines and turbocharger models, ensuring a seamless integration into the existing system. Following the manufacturer’s guidelines for installation will help ensure that the connection functions as intended, providing the full range of benefits it offers.

Maintenance and Troubleshooting

Regular maintenance of the Turbocharger Oil Drain Connection is important for its longevity and efficiency. This includes periodic checks for leaks, ensuring that the connection is securely fastened, and following the recommended oil change intervals. Common issues that may arise include oil leaks or difficulty in draining, which can often be resolved by inspecting the connection for damage or blockages and making necessary adjustments or replacements.

Performance Impact

The Turbocharger Oil Drain Connection contributes to the overall performance of the turbocharger and the engine by ensuring that the lubrication system operates efficiently. This can lead to measurable improvements in engine efficiency and power output, as the turbocharger is able to maintain optimal performance without the risk of lubrication-related issues.

Cummins Overview

Cummins Inc. has a long history of excellence in manufacturing diesel engines and related components. Founded in 1919, the company has grown to become a global leader in the industry, known for its innovation, quality, and commitment to customer satisfaction. Cummins’ expertise in turbocharger technology and component design is evident in the Turbocharger Oil Drain Connection, which embodies the company’s dedication to providing reliable and efficient solutions for the automotive industry.

Turbocharger Oil Drain Connection for Cummins Engines

The Turbocharger Oil Drain Connection, part 3926842, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engine models. This part is crucial for maintaining the health and efficiency of the turbocharger by ensuring proper oil drainage. Below are the Cummins engines that are compatible with this turbocharger oil drain connection:

6C8.3 Series

- 6C8.3

C GAS PLUS Series

- C GAS PLUS CM556

C8.3 Series

- C8.3 G

G8.3 Series

- G8.3

GTA8.3 Series

- GTA8.3 CM558

L8.9 Series

- L8.9

- L8.9 CM2670 L134C

- L8.9 L121

- L8.9G CMOH2.0 L125B

L9.3 Series

- L9.3 L105

L9.5 Series

- L9.5 L117

QSC8.3 Series

- QSC8.3 CM2880 C102

QSL9 Series

- QSL9 CM850 (CM2850)

- QSL9.3 CM2880 L113

This turbocharger oil drain connection is engineered to ensure compatibility and reliability across these engine models, facilitating efficient oil drainage and contributing to the overall performance and longevity of the turbocharger system.

Understanding the Role of Part 3926842 Turbocharger Oil Drain Connection in Engine Systems

In modern engine systems, the turbocharger oil drain connection, specifically part 3926842, serves an essential function in maintaining the efficiency and reliability of the turbocharger. This component is integral to the turbocharger plumbing system, ensuring that the oil used for lubricating the turbocharger is effectively drained and managed.

Integration with Turbocharger Plumbing

The turbocharger plumbing system is designed to circulate oil to various parts of the turbocharger, including the bearings and other moving components. Part 3926842, the turbocharger oil drain connection, is a key element in this system. It facilitates the drainage of used oil from the turbocharger, which is then either recycled back into the lubrication system or disposed of, depending on the engine’s design and maintenance protocols.

Interaction with the Turbocharger

Within the turbocharger, the oil drain connection is strategically positioned to allow for the efficient removal of oil that has lubricated the turbocharger’s internal components. This process is vital for preventing oil buildup, which can lead to increased friction and potential damage to the turbocharger. The proper functioning of part 3926842 ensures that the turbocharger operates within optimal parameters, enhancing its longevity and performance.

Role in the Overall Engine System

In the broader context of the engine system, the turbocharger oil drain connection plays a part in the engine’s lubrication and cooling mechanisms. By ensuring that the turbocharger is properly lubricated and that excess oil is efficiently drained, this component contributes to the overall stability and performance of the engine. It helps in maintaining the correct oil levels and pressure, which are critical for the engine’s operation.

Conclusion

Understanding the role of part 3926842 in the turbocharger and engine system highlights the importance of each component in ensuring the engine’s efficiency, reliability, and longevity. Proper maintenance and attention to the turbocharger oil drain connection are essential for the optimal performance of the turbocharger and, by extension, the entire engine system.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.