This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection, identified by part number 3927307, is a component manufactured by Cummins, a leader in diesel engine technology. This part is integral to the turbocharger system, facilitating the management of oil within the turbocharger. Cummins, known for its commitment to innovation and quality, ensures that this component meets the rigorous demands of heavy-duty truck operations 1.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger oil drain connections are designed to manage the flow of lubrication oil within the turbocharger system. These connections play a role in maintaining the turbocharger’s performance and longevity by ensuring that oil is efficiently drained from the turbocharger. Proper oil management is vital for reducing wear on turbocharger components, maintaining optimal lubrication, and ensuring the turbocharger operates within its designed parameters 2.

Purpose and Role in Truck Operation

In the context of heavy-duty truck operations, the Turbocharger Oil Drain Connection serves to facilitate the efficient drainage of oil from the turbocharger. This process is important for maintaining the turbocharger’s efficiency and, by extension, the engine’s performance. By ensuring that oil is properly managed and drained, the connection helps to prevent oil buildup, which can lead to decreased turbocharger efficiency and potential damage. This, in turn, contributes to the overall reliability and performance of the engine 3.

Key Features

The Turbocharger Oil Drain Connection by Cummins is designed with several key features that enhance its functionality and reliability. These include a robust material composition that withstands the high pressures and temperatures within the turbocharger system. The connection also incorporates sealing mechanisms that ensure a secure fit, preventing oil leaks that could compromise turbocharger performance. Additionally, it is specifically engineered to be compatible with Cummins turbochargers, ensuring seamless integration and optimal performance.

Benefits

Using the Turbocharger Oil Drain Connection in heavy-duty trucks offers several benefits. It contributes to improved turbocharger efficiency by ensuring that oil is effectively managed and drained. This leads to enhanced engine performance, as the turbocharger operates more efficiently. Additionally, proper oil management can extend the lifespan of turbocharger components, potentially leading to cost savings through reduced maintenance and replacement needs.

Troubleshooting and Maintenance Suggestions

To ensure the optimal performance and longevity of the Turbocharger Oil Drain Connection, regular maintenance is recommended. This includes checking for any signs of wear or damage, ensuring that the sealing mechanisms are intact, and verifying that the connection is securely fitted. Troubleshooting common issues may involve inspecting for oil leaks, which could indicate a faulty seal or improper fitting. Addressing these issues promptly can help maintain the efficiency of the turbocharger and the overall performance of the engine.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including diesel and natural gas engines, as well as related technologies. With a history spanning over a century, Cummins has established itself as a trusted name in the automotive industry, particularly in the realm of diesel engine technology. The company’s commitment to innovation, quality, and customer satisfaction is evident in its turbocharger components, which are designed to meet the demanding requirements of heavy-duty applications.

Turbocharger Oil Drain Connection for Cummins Engines

The turbocharger oil drain connection, part number 3927307, is a critical component in the lubrication system of certain Cummins engines. This part is designed to facilitate the drainage of oil from the turbocharger, ensuring that the turbocharger operates efficiently and reliably.

Compatibility with Cummins Engines

The turbocharger oil drain connection is specifically engineered to fit the following Cummins engines:

- 6C8.3

- C8.3 G

These engines are part of the broader range of Cummins diesel engines known for their durability and performance in various applications, including industrial, marine, and power generation sectors.

Installation and Functionality

The installation of the turbocharger oil drain connection is straightforward, designed to integrate seamlessly with the engine’s existing oil system. This part is crucial for maintaining the health of the turbocharger by allowing the oil to be drained back into the engine’s oil sump, preventing oil starvation and ensuring that the turbocharger’s bearings and other moving parts remain adequately lubricated.

Importance in Engine Maintenance

Regular maintenance of the turbocharger oil drain connection is essential to prevent oil leaks and ensure the longevity of the turbocharger. This part should be inspected periodically for any signs of wear or damage, and replaced if necessary to maintain optimal engine performance.

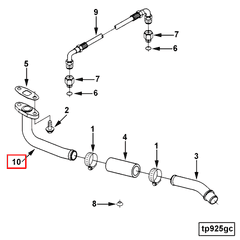

Role of Part 3927307 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection, identified by part number 3927307, is an integral component in the maintenance and operation of turbocharged engine systems. This part is specifically designed to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters.

Integration with Turbocharger

In turbocharged engines, the turbocharger is a high-speed component that requires consistent lubrication to reduce friction and wear. The Turbocharger Oil Drain Connection is strategically positioned to allow for the periodic removal of oil that has been circulated through the turbocharger. This process helps in maintaining the cleanliness and viscosity of the oil, which is essential for the turbocharger’s bearings and other moving parts.

Interaction with Plumbing Systems

The Turbocharger Oil Drain Connection interfaces with the engine’s plumbing system, which includes oil lines and drainage pathways. This connection point is typically integrated into the oil return line, allowing drained oil to flow back into the sump or oil pan. Proper installation and sealing of this connection are vital to prevent oil leaks and ensure that the drainage process is both efficient and contained within the engine’s lubrication system.

Maintenance and Operational Benefits

By incorporating the Turbocharger Oil Drain Connection into the engine system, mechanics and engineers can perform routine maintenance tasks more effectively. Regular oil changes and inspections of the turbocharger’s oil system are simplified, leading to enhanced engine performance and longevity. Additionally, this component aids in the early detection of potential issues within the turbocharger’s lubrication system, allowing for timely interventions and repairs.

Conclusion

In summary, the Turbocharger Oil Drain Connection (part 3927307) plays a significant role in the turbocharged engine’s lubrication and maintenance processes. Its proper function and integration with both the turbocharger and the engine’s plumbing system are essential for the overall health and efficiency of the engine.

-

Vehicle Dynamics and Control, Rajesh Rajamani, Springer, 2005

↩ -

Brakes Brake Control and Driver Assistance Systems Function Regulation and Components, Konrad Reif Ed, Springer, 2014

↩ -

Automotive Emissions Regulations and Exhaust Aftertreatment Systems, John Kasab and Andrea Strzelec, SAE International, 2020

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.