This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Turbocharger Oil Drain Connection (Part #3933199) manufactured by Cummins is designed to facilitate the drainage of oil from the turbocharger system. This part ensures that the turbocharger operates efficiently by allowing for the removal of used oil, which can accumulate contaminants and degrade over time. Proper maintenance of this connection is important for the longevity and performance of the turbocharger system.

Basic Concepts of Turbocharger Oil Drain Connection

Turbochargers operate by using exhaust gases to spin a turbine, which in turn drives a compressor to increase the amount of air entering the engine. This process enhances engine performance by allowing for more fuel to be burned in each cycle. Oil lubrication is necessary to reduce friction and wear on the turbocharger’s moving parts. The oil drain connection is integral to this system as it provides a means for the used oil to be drained from the turbocharger, ensuring that fresh, clean oil circulates through the system 1.

Function and Operation

The Turbocharger Oil Drain Connection operates by allowing oil to be drained from the turbocharger system at regular intervals. The oil circulation process involves oil being pumped into the turbocharger to lubricate the turbine and compressor. As the oil circulates, it picks up contaminants and heat. The drain connection provides a point where the oil can be expelled, allowing for fresh oil to replace it. This helps maintain the efficiency and reliability of the turbocharger 2.

Purpose of the Turbocharger Oil Drain Connection

In the context of heavy-duty truck engines, the Turbocharger Oil Drain Connection contributes to the overall performance and longevity of the turbocharger. By enabling the regular drainage of used oil, it helps ensure that the turbocharger remains well-lubricated and operates within optimal parameters. This, in turn, supports the engine’s performance and durability.

Key Features

The Turbocharger Oil Drain Connection features a robust design that incorporates high-quality materials to withstand the harsh conditions within a turbocharger system. Its design elements include precision-machined fittings to ensure a secure connection and prevent leaks. The materials used are selected for their durability and resistance to corrosion, enhancing the part’s functionality and lifespan.

Benefits

Using the Turbocharger Oil Drain Connection offers several benefits. It contributes to improved engine performance by ensuring that the turbocharger system remains well-lubricated. Regular drainage of used oil reduces the frequency of maintenance intervals, as it helps prevent the buildup of contaminants that can lead to wear and efficiency losses. Additionally, the reliable operation of the drain connection enhances the overall reliability of the turbocharger system.

Installation Process

Installing the Turbocharger Oil Drain Connection involves several steps to ensure proper integration into the turbocharger system. Begin by ensuring the engine is cool and the turbocharger system is depressurized. Locate the drain connection point on the turbocharger and align the part with the fitting. Secure the connection using the appropriate tools, ensuring a tight seal to prevent leaks. Finally, verify the installation by checking for any signs of leakage or improper fitting.

Maintenance and Troubleshooting

Regular maintenance of the Turbocharger Oil Drain Connection involves periodic inspection for signs of wear or damage. It is important to drain the oil at recommended intervals to prevent the accumulation of contaminants. Common issues that may arise include leaks at the connection point or blockages within the drain line. Troubleshooting these issues involves inspecting the connection for proper seating, checking for debris in the drain line, and ensuring that the oil pump is functioning correctly.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history of innovation and a commitment to quality, Cummins plays a significant role in the automotive industry by providing high-quality turbocharger components that enhance engine performance and efficiency 3.

Application in Cummins Engines

4B3.9 and 6B5.9 Engines

The Turbocharger Oil Drain Connection part number 3933199 is compatible with the 4B3.9 and 6B5.9 engines. These engines are part of Cummins’ range of high-performance diesel engines, known for their durability and efficiency. The turbocharger oil drain connection plays a vital role in maintaining the health of the turbocharger by allowing the excess oil to be drained back into the engine’s oil system. This helps in preventing oil from entering the turbine section of the turbocharger, which can lead to inefficient operation and potential damage.

In these engines, the turbocharger oil drain connection is strategically placed to ensure that the oil is effectively managed. This connection is typically located at the base of the turbocharger, where it can efficiently channel the oil back into the engine’s lubrication system. The design of the part ensures that it can withstand the high temperatures and pressures found in the engine environment, making it a reliable component for these applications.

The use of the Turbocharger Oil Drain Connection part number 3933199 in the 4B3.9 and 6B5.9 engines highlights Cummins’ commitment to providing high-quality, durable components that enhance the performance and longevity of their engines. This part is essential for maintaining the efficiency and reliability of the turbocharger, ensuring that the engine operates at peak performance.

Role of Part 3933199 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection (Part 3933199) is an integral component in the maintenance and operation of engine systems, particularly those involving turbochargers. This part facilitates the essential function of draining oil from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters.

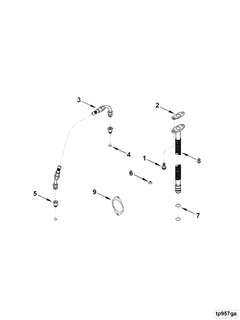

Integration with Turbocharger Plumbing

In the context of turbocharger plumbing, the Turbocharger Oil Drain Connection serves as a vital junction. It is strategically positioned to allow for the periodic removal of oil that has circulated through the turbocharger. This oil, after lubricating the turbocharger’s moving parts, may contain contaminants or may have degraded over time. The drain connection enables mechanics to purge this oil, replacing it with fresh lubricant to maintain the integrity of the turbocharger’s bearings and other internal components.

Interaction with the Turbocharger

The turbocharger itself relies on a consistent supply of clean oil for lubrication. The Turbocharger Oil Drain Connection plays a key role in this process by ensuring that old or contaminated oil does not accumulate, which could lead to increased friction, wear, and potentially catastrophic failure of the turbocharger. Regular maintenance through this connection helps in prolonging the turbocharger’s lifespan and ensuring it operates at peak efficiency.

Importance in Overall Engine System

Within the broader engine system, the Turbocharger Oil Drain Connection is a component that supports the health and performance of the turbocharger, which in turn affects the engine’s overall efficiency and power output. By facilitating the removal of used oil, it helps in maintaining the turbocharger’s ability to compress air effectively, which is essential for the engine’s combustion process and power generation.

Conclusion

In summary, the Turbocharger Oil Drain Connection (Part 3933199) is a component that, while small in size, plays a significant role in the maintenance and operational efficiency of turbochargers and, by extension, the engine systems they are a part of. Its proper use and maintenance are key to ensuring the longevity and performance of the turbocharger and the engine as a whole.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.