3934064

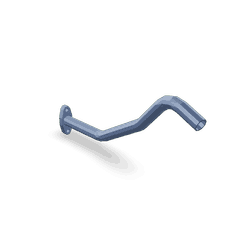

Turbocharger Oil Drain Connection

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection (Part #3934064) by Cummins is a component designed to facilitate the drainage of oil from the turbocharger system in heavy-duty trucks. Its purpose is to ensure that excess oil is efficiently removed from the turbocharger, contributing to the overall health and performance of the engine. This part plays a role in maintaining the turbocharger’s operational integrity by preventing oil buildup, which can lead to decreased efficiency and potential damage 1.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger oil drain connections operate on the principle of allowing used or excess oil to be expelled from the turbocharger system. This process is vital for maintaining the turbocharger’s lubrication system, which is important for its efficient operation. By ensuring that old oil is regularly drained, the system can maintain optimal lubrication, reduce the risk of contamination, and enhance the turbocharger’s longevity. The proper functioning of these connections is integral to the turbocharger’s ability to compress intake air, thereby improving engine performance 2.

Role and Function of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection is specifically designed to play a role in the oil management system of a truck’s turbocharger. It allows for the controlled drainage of oil, which helps in maintaining the correct oil level within the turbocharger. This part contributes to the turbocharger’s efficiency by ensuring that the lubrication system operates within specified parameters, thus supporting consistent performance and reliability 3.

Key Features of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection is characterized by its robust design and the use of high-quality materials, which enhance its performance and durability. It is engineered to withstand the high pressures and temperatures typical of turbocharger environments. Additionally, its design incorporates features that facilitate easy installation and maintenance, ensuring that it can be efficiently integrated into the turbocharger system 4.

Benefits of Using the Turbocharger Oil Drain Connection

Utilizing the Turbocharger Oil Drain Connection offers several advantages. It contributes to improved turbocharger performance by ensuring efficient oil drainage, which helps maintain optimal lubrication. This can lead to enhanced reliability of the turbocharger system and potentially reduce maintenance costs over time by preventing issues related to oil buildup and contamination 5.

Troubleshooting and Maintenance Tips

Identifying common issues with turbocharger oil drain connections can involve checking for signs of oil leaks or unusual noises from the turbocharger. Troubleshooting may require inspecting the connection for blockages or damage. Regular maintenance practices, such as periodic checks for wear and ensuring the connection is securely fitted, can help maintain optimal performance and longevity of the turbocharger system 6.

Integration with Turbocharger Systems

The Turbocharger Oil Drain Connection is designed to integrate seamlessly with various turbocharger systems found in heavy-duty trucks. Compatibility considerations include ensuring the connection matches the specific turbocharger model and fits within the existing system architecture. Proper installation procedures involve following manufacturer guidelines to ensure a secure and efficient integration 7.

Impact on Engine Performance

The proper functioning of the Turbocharger Oil Drain Connection influences overall engine performance by supporting the turbocharger’s efficiency. This can lead to improvements in power output, fuel efficiency, and emissions. By maintaining optimal turbocharger health, the connection indirectly contributes to the engine’s ability to operate at peak performance levels 8.

Manufacturer Overview - Cummins

Cummins is a well-established manufacturer in the automotive industry, known for its commitment to producing high-quality components for heavy-duty trucks. With a history of innovation and excellence, Cummins has built a reputation for reliability and performance. The company’s dedication to quality is evident in its range of turbocharger components, including the Turbocharger Oil Drain Connection, which is designed to meet the demanding requirements of heavy-duty applications 9.

Turbocharger Oil Drain Connection (Part 3934064) in Cummins Engines

The Turbocharger Oil Drain Connection, identified by the part number 3934064, is a component in the maintenance and operation of several Cummins engines. This part is designed to facilitate the drainage of oil from the turbocharger, ensuring that the system remains clean and free from contaminants that could otherwise lead to performance degradation or failure.

Application in Cummins Engines

4B3.9 Engine Group

The 4B3.9 engine series, manufactured by Cummins, utilizes the Turbocharger Oil Drain Connection to maintain optimal turbocharger performance. This connection is integral to the engine’s lubrication system, allowing for the efficient removal of oil that has been used to lubricate the turbocharger’s moving parts. By ensuring that used oil is effectively drained, the part helps to prevent the buildup of sludge and other contaminants that can impair the turbocharger’s efficiency and longevity.

The Turbocharger Oil Drain Connection is engineered to fit seamlessly within the 4B3.9 engine’s design, providing a reliable pathway for oil to exit the turbocharger and enter the engine’s oil system. This connection is typically made from durable materials that can withstand the high temperatures and pressures encountered in the engine environment, ensuring a long service life and consistent performance.

The integration of the Turbocharger Oil Drain Connection in the 4B3.9 engine series highlights Cummins’ commitment to providing high-quality, reliable components that enhance engine performance and durability. This part is important for maintaining the health of the turbocharger and, by extension, the overall efficiency and reliability of the engine 10.

Role of Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection (Part 3934064) is a component in the maintenance and operation of turbocharged engine systems. Its primary function is to facilitate the drainage of oil from the turbocharger, ensuring that the oil does not accumulate and potentially cause damage to the turbocharger or other engine components.

Integration with Turbocharger

In turbocharged engines, the turbocharger operates at extremely high speeds and temperatures. The Turbocharger Oil Drain Connection is strategically positioned to allow for the periodic release of oil that has been used to lubricate the turbocharger’s bearings and other moving parts. This drainage process helps maintain optimal lubrication and prevents oil buildup, which could lead to increased friction and wear.

Interaction with Plumbing Systems

The Turbocharger Oil Drain Connection is also integral to the engine’s plumbing system. It is connected to the oil return lines, which direct the drained oil back to the sump or oil pan. This ensures that the oil can be recirculated and reused, promoting efficient oil management within the engine. The connection point must be secure and leak-free to prevent oil loss and maintain proper oil levels.

Maintenance and Operational Efficiency

Regular drainage of oil from the turbocharger is vital for maintaining the turbocharger’s efficiency and longevity. The Turbocharger Oil Drain Connection plays a role in this process by providing a reliable and convenient method for oil removal. Engineers and mechanics must ensure that this connection is properly installed and functioning correctly to avoid potential issues such as oil starvation or contamination.

Summary of Component Interaction

- Turbocharger: The connection allows for the necessary drainage of oil used in lubricating the turbocharger’s components.

- Plumbing System: It interfaces with the oil return lines to ensure that drained oil is efficiently returned to the sump for recirculation.

Understanding the role of the Turbocharger Oil Drain Connection (Part 3934064) in these systems highlights its importance in the overall health and performance of turbocharged engines 11.

Conclusion

The Turbocharger Oil Drain Connection (Part 3934064) by Cummins is a critical component for maintaining the efficiency and reliability of turbocharged engine systems. By facilitating the drainage of oil from the turbocharger, it ensures optimal lubrication, prevents oil buildup, and contributes to the overall performance of the engine. Regular maintenance and proper installation of this part are essential for maximizing the longevity and efficiency of the turbocharger and the engine as a whole.

-

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Maclaurin, B. (2018). High Speed Off-Road Vehicles. Wiley.

↩ -

Cummins Inc. (n.d.). Service Manual (6314873).

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩ -

Thompson, R. (2019). Automotive Maintenance: Light Repair. Cengage Learning.

↩ -

Cummins Inc. (n.d.). Service Manual (6314873).

↩ -

Maclaurin, B. (2018). High Speed Off-Road Vehicles. Wiley.

↩ -

Cummins Inc. (n.d.). Service Manual (6314873).

↩ -

Cummins Inc. (n.d.). Service Manual (6314873).

↩ -

Gilles, T. (2020). Automotive Service: Inspection, Maintenance, Repair: 2nd Edition. Cengage Learning.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.