This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection, identified by part number 3934084, is a component manufactured by Cummins, a leading provider of diesel engines and related technologies. This part is integral to the operation of heavy-duty truck engines, facilitating the efficient management of oil within the turbocharger system. Understanding its function and significance is vital for maintaining optimal engine performance and reliability.

Basic Concepts

Turbochargers are devices that increase the efficiency and power output of diesel engines by compressing the intake air before it enters the combustion chamber. This compression allows for more fuel to be burned, resulting in enhanced engine performance. Oil lubrication plays a role in turbocharger operation, ensuring that moving parts within the turbocharger operate smoothly and efficiently. Proper lubrication reduces friction, minimizes wear, and helps dissipate heat generated during operation 1.

Purpose of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection serves a specific function within the turbocharger system. It is designed to facilitate the circulation and drainage of oil, ensuring that the turbocharger remains properly lubricated. This connection allows for the periodic removal of used oil, which can become contaminated with particles and lose its lubricating properties over time. By enabling the drainage of old oil and the introduction of fresh lubricant, this component helps maintain the turbocharger’s efficiency and longevity 2.

Key Features

The Turbocharger Oil Drain Connection is engineered with several design and construction features that enhance its functionality. Constructed from durable materials, it is built to withstand the high pressures and temperatures associated with turbocharger operation. The connection type is designed for secure attachment to the turbocharger, ensuring a reliable seal that prevents oil leaks. Unique design elements may include anti-corrosion coatings and precision-machined surfaces to ensure optimal performance and durability 3.

Benefits

Incorporating the Turbocharger Oil Drain Connection into a turbocharger system offers several advantages. It contributes to improved engine performance by ensuring that the turbocharger operates with minimal friction and maximum efficiency. Enhanced reliability is another benefit, as proper lubrication and regular oil changes help prevent turbocharger failure. Additionally, the design of this connection simplifies maintenance procedures, allowing for easier and more efficient oil changes and inspections.

Installation and Compatibility

Proper installation of the Turbocharger Oil Drain Connection is crucial for its effective operation. Guidelines for installation include ensuring a secure and leak-free connection to the turbocharger. Specific requirements may vary depending on the engine model, so it is important to consult Cummins’ installation instructions for engines to which this part is applicable. Compatibility with Cummins engines is ensured through rigorous testing and design standards, guaranteeing optimal performance and reliability when used as specified.

Maintenance and Troubleshooting

Routine maintenance of the Turbocharger Oil Drain Connection is straightforward but important for ensuring its continued effectiveness. Inspection intervals should be followed to check for signs of wear, corrosion, or leaks. Cleaning procedures may involve flushing the oil system to remove contaminants and ensure fresh lubricant is circulated. Common troubleshooting steps for potential issues include checking for proper connection seals, inspecting for damage, and ensuring that oil levels are maintained within the recommended range.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the commercial truck industry. The company’s product offerings include a wide range of diesel and natural gas engines, as well as related technologies such as turbochargers and emissions solutions. Cummins’ commitment to excellence and customer satisfaction has made it a preferred choice for heavy-duty truck applications worldwide.

Turbocharger Oil Drain Connection Compatibility with Cummins Engines

The Turbocharger Oil Drain Connection part number 3934084, manufactured by Cummins, is designed to fit seamlessly with a variety of Cummins engine models. This part is crucial for maintaining the health and efficiency of the turbocharger by ensuring proper oil drainage. Below is a detailed description of its compatibility across different engine series.

Cummins 4B3.9 and QSB3.9 30 CM550 Engines

The Turbocharger Oil Drain Connection part 3934084 is compatible with the Cummins 4B3.9 and QSB3.9 30 CM550 engines. These engines are known for their robust performance and reliability, often used in a variety of industrial and agricultural applications. The part ensures that the turbocharger oil is efficiently drained, preventing oil accumulation that could lead to performance degradation.

Cummins 6B5.9 and QSB6.7 CM850 (CM2850) Engines

For the Cummins 6B5.9 and QSB6.7 CM850 (CM2850) engines, the Turbocharger Oil Drain Connection part 3934084 is engineered to fit perfectly. These engines are part of the Cummins QSB series, which is renowned for its power and durability. The part’s design ensures that oil is effectively drained from the turbocharger, maintaining optimal engine performance.

Cummins 6C8.3, G8.3, and C8.3 G Engines

The Turbocharger Oil Drain Connection part 3934084 is also compatible with the Cummins 6C8.3, G8.3, and C8.3 G engines. These engines are part of the Cummins C and G series, known for their versatility and efficiency. The part’s precise fit ensures that oil is properly drained, contributing to the longevity and reliability of these engines.

Cummins C GAS PLUS CM556 and ISBE CM800 Engines

The part 3934084 is also suitable for the Cummins C GAS PLUS CM556 and ISBE CM800 engines. These engines are part of the Cummins C and ISBE series, which are widely used in various applications due to their performance and efficiency. The Turbocharger Oil Drain Connection ensures that oil is efficiently drained, preventing potential issues related to oil accumulation.

Cummins QSB7 CM2880 B117 Engine

Lastly, the Turbocharger Oil Drain Connection part 3934084 fits the Cummins QSB7 CM2880 B117 engine. This engine is part of the Cummins QSB series, known for its power and reliability. The part’s design ensures that oil is effectively drained from the turbocharger, maintaining the engine’s performance and longevity.

By ensuring a proper fit with these various engine models, the Turbocharger Oil Drain Connection part 3934084 plays a vital role in maintaining the efficiency and reliability of Cummins engines across different applications.

Role of Part 3934084 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection, identified as part 3934084, is a component in the efficient operation of turbocharger systems within engine assemblies. This part is specifically designed to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains effective and that oil does not accumulate to problematic levels.

Integration with Turbocharger Plumbing

In the context of turbocharger plumbing, part 3934084 serves as a vital junction. It connects to the turbocharger’s internal oil passages, allowing for the controlled release of oil back into the engine’s lubrication system. This connection is typically found at the bottom of the turbocharger, where oil collects after lubricating the turbine and compressor wheels.

Function within Turbocharger Oil Plumbing

Within the turbocharger oil plumbing system, the Turbocharger Oil Drain Connection plays a role. It ensures that oil, after performing its lubricating duties within the turbocharger, is efficiently drained. This prevents oil buildup, which could lead to increased temperatures and potential damage to the turbocharger components. The drained oil is then returned to the engine’s oil sump, where it is recirculated and reused, contributing to the overall efficiency of the lubrication system.

Interaction with Turbocharger Components

The Turbocharger Oil Drain Connection is intricately linked with various turbocharger components. It interfaces directly with the turbocharger’s bearing housing, where the oil is initially directed to lubricate the rotating assemblies. After lubrication, the oil flows to the drain connection, where it is expelled from the turbocharger. This process is essential for maintaining the optimal performance and longevity of the turbocharger.

Importance in Turbocharger Oil System

In the turbocharger oil system, the role of part 3934084 cannot be overstated. It ensures that the oil, which is vital for the turbocharger’s operation, is managed effectively. By providing a reliable drainage path, it helps in maintaining the correct oil levels within the turbocharger, thus supporting consistent performance and reducing the risk of oil-related failures.

Conclusion

In summary, the Turbocharger Oil Drain Connection (part 3934084) is a key element in the turbocharger’s oil management system. Its proper function is essential for the efficient operation of turbocharger plumbing, turbocharger oil systems, and the overall health of the turbocharger itself. Engineers and mechanics must ensure this component is correctly installed and maintained to uphold the performance standards of the engine system.

-

Hilgers, Michael. Fuel Consumption and Consumption Optimization, Second Edition. Springer Nature, 2023.

↩ -

ElGindy, Moustafa and ElSayegh, Zeinab. Road and Off-Road Vehicle Dynamics. Springer Nature, 2023.

↩ -

Sully, F. K. Motor Vehicle Mechanics Textbook, Fifth Edition. Heinemann Professional Publishing, 1998.

↩

SPECIFICATIONS

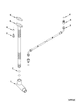

BILL OF MATERIALS

| Name | Quantity | Part Number |

|---|---|---|

| O Ring Seal | 2 | 3928624 |

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.