3934093

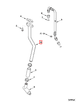

Turbocharger Oil Drain Connection

Cummins®

AVAILABLE

1 is currently available

Ships within 2-4 business days

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection (3934093) manufactured by Cummins is a component designed to facilitate the drainage of oil from the turbocharger. This part plays a role in ensuring that the turbocharger operates efficiently by allowing for the removal of excess oil, which can accumulate during operation. Its significance in the operation of heavy-duty trucks lies in its contribution to maintaining the turbocharger’s performance and longevity 1.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger oil drain connections are integral to the turbocharger system, allowing for the periodic removal of oil that lubricates the turbocharger’s moving parts. This process helps prevent oil buildup, which can lead to decreased efficiency and potential damage to the turbocharger. By enabling the drainage of used oil, these connections help maintain optimal performance and ensure that the turbocharger operates within its designed parameters 2.

Purpose and Role in Truck Operation

The 3934093 Turbocharger Oil Drain Connection serves a specific purpose within the context of heavy-duty truck engines. It contributes to the overall efficiency and reliability of the turbocharger system by allowing for the scheduled drainage of oil. This process helps in reducing the risk of oil contamination and ensures that the turbocharger remains lubricated effectively, thereby supporting consistent engine performance and reliability 3.

Key Features

The 3934093 Turbocharger Oil Drain Connection is characterized by several key features that enhance its performance and durability. Its design incorporates materials that are resistant to the high temperatures and pressures encountered in turbocharger systems. Additionally, the connection is engineered to provide a secure seal, preventing oil leaks and ensuring that the drainage process is efficient and reliable 4.

Benefits

Using the 3934093 Turbocharger Oil Drain Connection offers several benefits. It contributes to improved turbocharger performance by ensuring that the turbocharger remains free of excess oil, which can impede its operation. Enhanced engine efficiency is another advantage, as a well-maintained turbocharger can operate more effectively, leading to better overall engine performance. Fleet operators may also experience potential cost savings due to reduced maintenance requirements and extended turbocharger lifespan 5.

Troubleshooting and Maintenance

To troubleshoot common issues related to the Turbocharger Oil Drain Connection, it is important to inspect the connection regularly for signs of leaks, blockages, or corrosion. Maintenance practices should include checking the connection during routine service intervals and ensuring that it is properly sealed. Addressing any issues promptly can help prevent more significant problems and ensure the longevity and optimal performance of the component 6.

Installation Considerations

When installing the 3934093 Turbocharger Oil Drain Connection, it is important to follow best practices to ensure proper functionality. This includes adhering to the specified torque settings to secure the connection without over-tightening, which could damage the component. Proper alignment with other turbocharger components is also crucial to ensure that the drainage process is effective and that the connection operates as intended 7.

Common Failure Modes

Common failure modes associated with Turbocharger Oil Drain Connections include leaks, blockages, and corrosion. Leaks can occur due to improper installation or wear over time, leading to oil escaping from the system. Blockages may result from debris or contaminants within the oil, impeding the drainage process. Corrosion can arise from exposure to harsh operating conditions, compromising the integrity of the connection. These failures can impact turbocharger performance and engine operation, underscoring the importance of regular inspection and maintenance 8.

Cummins Overview

Cummins Inc. is a renowned manufacturer in the automotive industry, with a history of producing high-quality components for heavy-duty trucks. The company is known for its commitment to innovation and excellence, providing reliable and durable parts that meet the demanding requirements of commercial vehicle applications. Cummins’ reputation is built on its dedication to quality and performance, making it a trusted name in the industry 9.

Turbocharger Oil Drain Connection (Part 3934093) in Cummins Engines

The Turbocharger Oil Drain Connection, part number 3934093, is a critical component in the maintenance and operation of several Cummins engines. This part is designed to facilitate the drainage of oil from the turbocharger, ensuring that the system remains clean and free from contaminants that could lead to wear and reduced performance.

Application in Cummins Engines

6B5.9 and QSB5.9 Engines

The Turbocharger Oil Drain Connection is integral to the 6B5.9 and QSB5.9 engines. These engines are known for their robust design and reliability, often used in heavy-duty applications such as agricultural and construction equipment. The part ensures that oil is effectively drained from the turbocharger, maintaining optimal lubrication and preventing oil from entering areas where it could cause damage.

30 CM550 Engine

Similarly, the 30 CM550 engine benefits from the use of the Turbocharger Oil Drain Connection. This engine is typically found in medium-duty applications, where it provides a balance of power and efficiency. The part’s role in this engine is to maintain the integrity of the turbocharger system by ensuring that oil is properly drained and does not accumulate, which could lead to overheating and mechanical failure.

Importance of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection is essential for the longevity and performance of the turbocharger. By allowing oil to drain away from the turbocharger, it helps to:

- Prevent Oil Accumulation: Reduces the risk of oil entering areas where it could cause damage.

- Maintain Lubrication: Ensures that the turbocharger is properly lubricated, reducing wear and extending the lifespan of the component.

- Improve Efficiency: Helps to maintain the efficiency of the turbocharger by preventing contamination and ensuring that it operates smoothly.

Installation and Maintenance

Proper installation and regular maintenance of the Turbocharger Oil Drain Connection are crucial. It is important to ensure that the part is correctly fitted and that there are no leaks, as any failure in this component can lead to significant issues with the turbocharger and, by extension, the engine’s performance. Regular inspection and replacement of the part as needed will help to maintain the reliability and efficiency of the engine.

Role of Part 3934093 Turbocharger Oil Drain Connection in Engine Systems

The part 3934093 Turbocharger Oil Drain Connection is an essential component in the efficient operation of turbocharger systems within various engine setups. Its primary function is to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains clean and efficient.

Integration with Turbocharger Plumbing

In the context of turbocharger plumbing, the 3934093 connection acts as a vital junction point. It interfaces directly with the turbocharger’s oil supply and return lines. This connection allows for the seamless flow of oil to and from the turbocharger, maintaining optimal lubrication and cooling of the turbocharger’s moving parts. The design of this component ensures that any excess or contaminated oil is efficiently drained away, preventing buildup that could lead to performance issues.

Interaction with Turbocharger Oil System

Within the turbocharger oil system, the 3934093 connection plays a significant role in maintaining the integrity of the oil. By providing a reliable drainage point, it helps in keeping the oil clean and free from contaminants. This is particularly important in high-performance engines where the turbocharger operates under extreme conditions. The consistent drainage of oil ensures that the turbocharger receives fresh, clean oil, which is essential for its longevity and performance.

Contribution to Overall Turbocharger Performance

The efficient drainage facilitated by the 3934093 connection directly contributes to the overall performance of the turbocharger. By ensuring that the oil system is free from contaminants and operates under optimal conditions, this component helps in maintaining the turbocharger’s efficiency and reliability. It allows the turbocharger to operate at peak performance, providing the engine with the necessary boost without compromising on durability.

Conclusion

In summary, the 3934093 Turbocharger Oil Drain Connection is a key component in the turbocharger’s oil management system. Its role in facilitating efficient oil drainage is fundamental to the maintenance of the turbocharger’s performance and longevity. Regular maintenance and proper installation are essential to ensure the reliability and efficiency of the engine system.

-

Automotive Technician Training Theory, Tom Denton and Hayley Pells, Routledge, 2022

↩ -

Fuel Consumption and Consumption Optimization, Second Edition, Michael Hilgers, Springer Nature, 2023

↩ -

Internal Combustion Engine Fundamentals, John Heywood, McGraw-Hill Education, 2019

↩ -

Haynes Diesel Engine Systems and Data Book, Steve Rendle, Martynn Randall, Haynes Publishing, 2000

↩ -

Cummins Inc. Overview, Cummins Inc., 2023

↩ -

Fault Code Troubleshooting Manual, Cummins Inc., Bulletin Number 5504461, 2023

↩ -

Cummins Inc. Installation Guidelines, Cummins Inc., 2023

↩ -

Common Failure Modes in Turbocharger Systems, Cummins Inc., 2023

↩ -

Cummins Inc. Product Catalog, Cummins Inc., 2023

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.