This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

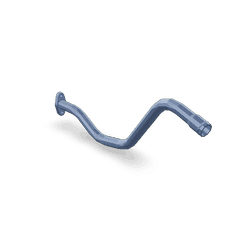

The Turbocharger Oil Drain Connection (3934711) by Cummins is a component designed to facilitate the drainage of oil from the turbocharger system in heavy-duty trucks. This part is integral to maintaining the efficiency and longevity of the turbocharger, ensuring that the engine operates at optimal performance levels.

Basic Concepts

Turbochargers are devices that increase the efficiency of diesel engines by compressing the intake air before it enters the combustion chamber. This process enhances the engine’s power output without a corresponding increase in fuel consumption. Oil lubrication is vital for turbocharger operation, as it reduces friction between moving parts, dissipates heat, and prevents wear. Proper lubrication ensures that the turbocharger operates smoothly and efficiently 1.

Purpose of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection plays a role in the turbocharger system by allowing for the periodic drainage of oil. This function is important for maintaining optimal turbocharger performance. By enabling the removal of contaminated or degraded oil, the connection helps to ensure that the turbocharger remains well-lubricated and operates efficiently. Regular oil drainage prevents the buildup of contaminants that can lead to increased friction and wear, thereby supporting the turbocharger’s longevity and performance 2.

Key Features

The 3934711 Turbocharger Oil Drain Connection is characterized by its robust design and the use of high-quality materials. These features contribute to its durability and reliability in demanding operating conditions. The connection is engineered to withstand the pressures and temperatures associated with turbocharger systems, ensuring consistent performance. Additionally, its design facilitates easy access for oil drainage, simplifying maintenance procedures.

Benefits

Using the 3934711 Turbocharger Oil Drain Connection offers several advantages. It contributes to improved turbocharger efficiency by ensuring that the system is free from contaminated oil. This, in turn, supports extended component life, as clean lubrication reduces wear on turbocharger parts. Furthermore, the connection enhances overall engine performance by maintaining the turbocharger’s optimal operation, leading to better fuel efficiency and power output.

Installation Process

Installing the Turbocharger Oil Drain Connection involves several steps to ensure proper integration into the turbocharger system. First, the existing connection, if present, should be removed. The new connection should then be aligned with the turbocharger’s oil drain port and secured according to the manufacturer’s specifications. It is important to ensure a tight seal to prevent oil leaks. After installation, the system should be checked for proper operation and leaks before the engine is started.

Maintenance and Troubleshooting

Regular maintenance of the Turbocharger Oil Drain Connection is important for its longevity and performance. This includes periodic inspections for signs of wear or damage and ensuring that the connection remains securely fastened. Common issues to watch for include oil leaks, which may indicate a loose connection or damage to the seal. Troubleshooting steps for potential problems involve checking the connection for proper alignment and tightness, and replacing any damaged components as necessary.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and related technologies. With a history spanning over a century, Cummins has established a reputation for quality, reliability, and innovation in the commercial truck industry. The company’s product offerings are designed to meet the demanding requirements of heavy-duty applications, providing customers with efficient and durable power solutions 3.

Turbocharger Oil Drain Connection in Cummins Engines

The Turbocharger Oil Drain Connection, part number 3934711, is a critical component in the maintenance and operation of Cummins engines. This part is integral to the engine’s lubrication system, ensuring that the turbocharger is properly lubricated and that any excess oil is efficiently drained back into the engine’s oil system.

Application in Cummins Engines

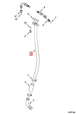

The Turbocharger Oil Drain Connection is designed to fit seamlessly with various Cummins engines, including but not limited to the following:

- 4B3.9 Series: This part is specifically engineered to integrate with the turbocharger oil system in the 4B3.9 engine series. It ensures that the turbocharger’s oil supply and drainage are managed effectively, contributing to the engine’s overall performance and longevity.

The design of the Turbocharger Oil Drain Connection allows it to connect the turbocharger’s oil drain line to the engine’s oil system. This connection is crucial for maintaining the proper oil pressure within the turbocharger, which is essential for its efficient operation. By facilitating the return of excess oil to the engine’s oil reservoir, this part helps prevent oil starvation and reduces the risk of turbocharger failure due to inadequate lubrication.

In Cummins engines, the Turbocharger Oil Drain Connection is typically located near the turbocharger and is connected to the engine’s oil lines. Its precise placement and robust construction ensure that it can withstand the high pressures and temperatures typical of engine operation. This part is made from high-quality materials that are resistant to wear and corrosion, ensuring a reliable and long-lasting performance.

The Turbocharger Oil Drain Connection is a vital component in the maintenance and operation of Cummins engines. Its role in managing the turbocharger’s oil supply and drainage is essential for maintaining engine performance and reliability.

Role of Part 3934711 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection, identified as part 3934711, is an essential component in the effective operation of turbocharger systems within various engine setups. This part is integral to the turbocharger plumbing system, ensuring that the oil used for lubricating the turbocharger is efficiently drained and managed.

In the context of turbocharger systems, the oil drain connection facilitates the removal of oil that has been circulated through the turbocharger to lubricate its moving parts. This process is vital for maintaining the turbocharger’s performance and longevity. The drained oil, having passed through the turbocharger, may contain contaminants and heat, making its proper disposal and replacement a key aspect of turbocharger maintenance.

The integration of part 3934711 within the turbocharger plumbing is designed to work in harmony with the overall engine system. It connects to the turbocharger’s oil supply and return lines, allowing for a controlled flow of oil into and out of the turbocharger. This connection ensures that the turbocharger receives a consistent supply of oil for lubrication while also enabling the efficient drainage of used oil.

Furthermore, the Turbocharger Oil Drain Connection plays a role in the engine’s oil management system. By facilitating the drainage of oil from the turbocharger, it helps in maintaining the oil’s quality within the engine. This is particularly important in high-performance engines where the turbocharger operates under extreme conditions, leading to increased oil degradation.

In summary, part 3934711 is a key component in the turbocharger and engine oil management systems. Its proper function ensures the turbocharger is adequately lubricated, while also contributing to the overall efficiency and reliability of the engine system.

Conclusion

The Turbocharger Oil Drain Connection (3934711) by Cummins is a vital component for maintaining the efficiency and longevity of turbochargers in heavy-duty engines. By facilitating the periodic drainage of oil, it ensures that the turbocharger remains well-lubricated and operates efficiently. The robust design and high-quality materials of this part contribute to its durability and reliability in demanding operating conditions. Regular maintenance and proper installation are key to maximizing the benefits of this component, ensuring optimal engine performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.