This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection, part number 3938603, is a component designed by Cummins to facilitate the efficient operation of turbochargers in heavy-duty trucks. This part plays a role in the turbocharger system by allowing for the drainage of oil, which is vital for maintaining the turbocharger’s performance and longevity. Cummins, a well-established manufacturer in the automotive industry, is known for producing reliable and high-quality components that enhance engine efficiency and durability 1.

Basic Concepts of Turbocharger Oil Drain Connection

Turbochargers are devices that increase an engine’s power output by forcing extra air into the combustion chamber. This process, known as forced induction, allows more fuel to be burned, resulting in increased power without a corresponding increase in engine size 2. The turbocharger oil drain connection is an integral part of this system. It provides a pathway for the oil that lubricates the turbocharger’s moving parts to be drained regularly. This drainage is important for preventing oil buildup, which can lead to decreased efficiency and potential damage to the turbocharger 3.

Purpose of the Turbocharger Oil Drain Connection

The primary function of the Turbocharger Oil Drain Connection is to ensure that the turbocharger remains efficiently lubricated. By allowing for the regular drainage of oil, this component helps maintain the optimal performance of the turbocharger. This, in turn, contributes to the overall efficiency and power output of the truck’s engine. Proper lubrication and maintenance of the turbocharger are key to achieving consistent engine performance and longevity 4.

Key Features

The Turbocharger Oil Drain Connection is designed with several features that enhance its functionality. Constructed from durable materials, this component is built to withstand the high temperatures and pressures associated with turbocharger operation. Its design ensures a secure fit and reliable performance. Additionally, the connection is engineered to facilitate easy maintenance, allowing for straightforward oil drainage and replacement when necessary.

Benefits of Using the Turbocharger Oil Drain Connection

Utilizing the Turbocharger Oil Drain Connection offers several advantages. It contributes to improved engine performance by ensuring that the turbocharger operates efficiently. The component’s design also enhances the reliability of the turbocharger system, reducing the likelihood of unexpected failures. Furthermore, the ease of maintenance provided by this oil drain connection simplifies regular upkeep, saving time and effort for truck operators and maintenance personnel.

Installation Process

Installing the Turbocharger Oil Drain Connection involves several steps to ensure proper fitting and functionality. The process begins with the removal of the old oil drain connection, if present. Next, the new connection is positioned and secured in place using the appropriate tools. It is important to follow the manufacturer’s guidelines to ensure a correct and safe installation. This may include torquing fasteners to specified values and verifying that all connections are tight and secure.

Maintenance and Care

Regular maintenance of the Turbocharger Oil Drain Connection is important for its longevity and efficiency. This includes periodic checks for leaks, ensuring that the connection remains secure, and draining the oil as recommended by the manufacturer. Using the correct lubricants and fluids is also important, as specified by Cummins, to maintain the turbocharger’s performance and protect its components from wear and damage.

Troubleshooting Common Issues

Common issues with turbocharger oil drain connections can include leaks, blockages, or improper drainage. These problems can often be identified through visual inspection and diagnostic checks. Solutions may involve tightening connections, cleaning or replacing parts, or ensuring that the oil drain process is functioning correctly. Addressing these issues promptly can help maintain the efficiency and reliability of the turbocharger system.

Compatibility and Application

The Turbocharger Oil Drain Connection is designed for use in specific types of engines and truck models. It is important to verify compatibility to ensure optimal performance and integration with the turbocharger system. Cummins provides detailed application notes and considerations to assist in selecting the correct component for a given engine and truck model.

Cummins: A Brief Overview

Cummins Inc. is a leading manufacturer of diesel engines, natural gas engines, and related technologies. With a history of innovation and a commitment to quality, Cummins has established a strong reputation in the automotive industry. The company’s products are known for their reliability, efficiency, and durability, making them a preferred choice for heavy-duty applications. Cummins continues to invest in research and development to advance its technologies and maintain its position as a leader in the market.

Turbocharger Oil Drain Connection for Cummins Engines

The Turbocharger Oil Drain Connection, part number 3938603, is a critical component in the lubrication system of certain Cummins engines. This part is designed to facilitate the drainage of oil from the turbocharger back to the engine’s oil system, ensuring that the turbocharger is properly lubricated while preventing oil from accumulating within the turbocharger housing.

Application in Cummins Engines

The Turbocharger Oil Drain Connection is integral to the following Cummins engine models:

- 4B3.9

This part is essential for maintaining the efficiency and longevity of the turbocharger by ensuring that oil is effectively drained and returned to the engine’s oil reservoir. The design and placement of the Turbocharger Oil Drain Connection are tailored to fit seamlessly within the architecture of these engines, providing a reliable and efficient means of oil management.

Role of Part 3938603 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection (part 3938603) is an essential component in the maintenance and operation of turbocharged engine systems. This part is specifically designed to facilitate the drainage of oil from the turbocharger, ensuring that the system operates efficiently and reliably.

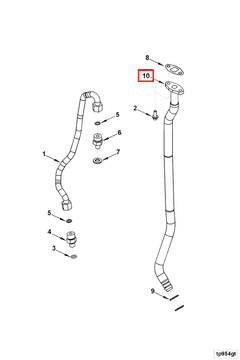

Integration with Turbocharger Plumbing

In turbocharged engines, the turbocharger oil drain connection is a key element of the turbocharger plumbing system. It is strategically positioned to allow for the periodic removal of oil that has been used to lubricate the turbocharger’s moving parts. This process is vital for maintaining the turbocharger’s performance and longevity. The connection point is usually integrated into the turbocharger’s oil supply and return lines, ensuring a seamless flow of oil through the system.

Function within the Turbocharger

The turbocharger itself relies on a consistent supply of oil to lubricate its bearings and other rotating components. The oil drain connection plays a significant role in this process by providing a means to remove contaminated or old oil from the system. This helps prevent the buildup of deposits and ensures that the turbocharger operates within optimal temperature ranges. Regular drainage through part 3938603 helps maintain the turbocharger’s efficiency and reduces the risk of mechanical failures.

Contribution to Overall Engine Performance

By ensuring that the turbocharger is properly lubricated and free from old or contaminated oil, the turbocharger oil drain connection indirectly contributes to the overall performance of the engine. A well-maintained turbocharger can significantly enhance engine power output, improve fuel efficiency, and reduce emissions. The drain connection is, therefore, a small but important component in the broader context of engine maintenance and performance optimization.

Maintenance and Inspection

Regular inspection and maintenance of the turbocharger oil drain connection are recommended to ensure it functions correctly. This includes checking for leaks, ensuring the connection is secure, and verifying that oil drainage occurs as expected. Proper maintenance of this part can lead to extended turbocharger life and improved engine reliability.

Conclusion

In summary, the turbocharger oil drain connection (part 3938603) is a vital component in the turbocharger plumbing system, playing a significant role in the lubrication and maintenance of the turbocharger. Its proper function is essential for the efficient operation of turbocharged engine systems.

-

Jazar, Reza N. Vehicle Dynamics: Theory and Application. Springer, 2017.

↩ -

Dixon, John C. Tyres Suspension and Handling Second Edition. SAE International, 1996.

↩ -

Bartz, Wilfried J. Engine Oils and Automotive Lubrication Mechanical Engineering Book 80. CRC Press, 2019.

↩ -

Cummins Inc. General Information. Bulletin Number 4960282, Owners Manual.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.