This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection, identified by Part #3942889, is a component manufactured by Cummins, a renowned name in the automotive industry. This part plays a role in the operation of heavy-duty truck engines, particularly in the maintenance and efficiency of turbochargers.

Basic Concepts of Turbocharger Oil Drain Connection

To understand the Turbocharger Oil Drain Connection, it is important to first grasp the fundamental principles behind turbochargers. Turbochargers are devices that increase an engine’s efficiency and power output by forcing extra air into the combustion chamber. The oil drain connection is integral to this process as it facilitates the drainage of oil from the turbocharger. This drainage is vital for maintaining the turbocharger’s efficiency and longevity, as it ensures that the turbocharger remains properly lubricated and cooled during operation 1.

Purpose and Function

The primary purpose of the Turbocharger Oil Drain Connection is to enable the drainage of oil from the turbocharger. This function is important for maintaining optimal lubrication and performance of the turbocharger. By allowing oil to be efficiently drained, the connection helps in preventing oil buildup, which can lead to decreased efficiency and potential damage to the turbocharger. This, in turn, contributes to the overall performance and reliability of the truck engine 2.

Key Features

The Turbocharger Oil Drain Connection is designed with several key features that enhance its functionality and durability. These include a robust construction that can withstand the high pressures and temperatures associated with turbocharger operation. The materials used in its construction are chosen for their strength and resistance to wear and corrosion. Additionally, the design of the connection ensures a secure fit, minimizing the risk of leaks and ensuring efficient oil drainage.

Benefits

Using the Turbocharger Oil Drain Connection offers several benefits. It contributes to improved engine performance by ensuring that the turbocharger operates efficiently. This efficiency translates to better overall engine performance. Additionally, the connection enhances the reliability of the turbocharger by facilitating proper lubrication and cooling. This can lead to reduced maintenance requirements, as a well-maintained turbocharger is less likely to experience issues or require repairs 3.

Installation and Compatibility

Proper installation of the Turbocharger Oil Drain Connection is important for its effective operation. Guidelines for installation should be followed to ensure compatibility with various truck models and engine types. Specific requirements or considerations for installation may include ensuring a secure fit and proper alignment with the turbocharger and engine components.

Maintenance and Troubleshooting

Maintaining the Turbocharger Oil Drain Connection is important for ensuring its optimal performance and longevity. Regular checks for leaks and proper function are recommended. Troubleshooting common issues related to oil drainage and turbocharger operation may involve inspecting the connection for signs of wear or damage and ensuring that it is securely fitted.

Cummins Overview

Cummins is a well-established manufacturer in the automotive industry, known for its high-quality components for commercial vehicles. With a history of innovation and a commitment to excellence, Cummins has built a reputation for reliability and performance. The company’s products, including the Turbocharger Oil Drain Connection, are designed with a focus on durability, efficiency, and compatibility with a wide range of engine types.

Turbocharger Oil Drain Connection (Part 3942889) in Cummins Engines

The Turbocharger Oil Drain Connection, identified as part number 3942889, is a component in the maintenance and operation of several Cummins engines. This part is integral to the turbocharger system, ensuring that oil is properly drained from the turbocharger, which is important for maintaining optimal engine performance and longevity.

Application in Cummins Engines

ISB CM550 and QSB5.9 44 CM550

The Turbocharger Oil Drain Connection is specifically designed to fit seamlessly with the ISB CM550 and QSB5.9 44 CM550 engines. These engines are known for their robust performance and reliability, often used in heavy-duty applications such as commercial vehicles and industrial machinery.

Compatibility and Functionality

In these engines, the Turbocharger Oil Drain Connection serves to:

- Facilitate the drainage of oil from the turbocharger, preventing oil accumulation that could lead to overheating and mechanical failure.

- Ensure a secure and leak-proof connection, maintaining the integrity of the turbocharger oil system.

- Support the overall efficiency of the turbocharger by ensuring that the oil is properly circulated and drained, contributing to the engine’s performance and durability.

Installation and Maintenance

Proper installation and regular maintenance of the Turbocharger Oil Drain Connection are crucial. This involves:

- Ensuring that the connection is correctly aligned and securely fastened to avoid leaks.

- Regularly inspecting the part for signs of wear or damage, replacing it as necessary to maintain the integrity of the turbocharger oil system.

- Using the correct tools and techniques during installation and maintenance to prevent damage to the part or the engine.

Role of Part 3942889 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection (Part 3942889) is a component in the maintenance and operation of turbochargers within engine systems. Its primary function is to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters.

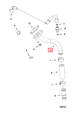

Integration with Turbocharger

In the context of a turbocharger, the oil drain connection is strategically positioned to allow for the periodic removal of oil that has circulated through the turbocharger’s bearings and other moving parts. This process is vital for maintaining the cleanliness and viscosity of the oil, which directly impacts the turbocharger’s performance and longevity. The connection point is usually located at the lower part of the turbocharger housing, ensuring that oil can be drained effectively without interfering with the turbocharger’s operation.

Interaction with Plumbing Systems

The Turbocharger Oil Drain Connection also plays a role in the engine’s plumbing system. It is connected to the oil drainage lines, which are part of the engine’s overall lubrication system. These lines are responsible for transporting the drained oil back to the oil sump or to a collection point where it can be analyzed for contaminants or recycled. The design of the connection ensures a secure and leak-proof seal, preventing any oil loss that could lead to reduced lubrication efficiency or environmental contamination.

Maintenance and Operational Efficiency

Regular maintenance of the Turbocharger Oil Drain Connection is essential for the operational efficiency of the engine. By ensuring that oil is properly drained and replaced, engineers and mechanics can prevent the buildup of contaminants that could otherwise lead to increased wear on turbocharger components. Additionally, the connection allows for the inspection of oil quality, providing valuable insights into the condition of the turbocharger and the engine as a whole.

Conclusion

In summary, the Turbocharger Oil Drain Connection (Part 3942889) is a key component in the maintenance and operation of turbochargers within engine systems. Its role in facilitating oil drainage, interacting with the engine’s plumbing system, and contributing to overall maintenance efficiency underscores its importance in ensuring the reliable and optimal performance of turbocharged engines.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.