3943820

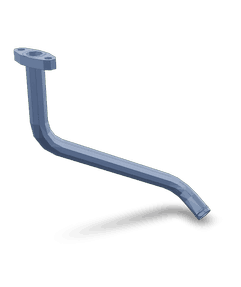

Turbocharger Oil Drain Connection

Cummins®

IN STOCK

1 is currently available

Ships within 1 business day

This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection (Part #3943820) manufactured by Cummins is a component designed to facilitate the efficient operation of the turbocharger system. This part plays a role in ensuring that oil is properly drained from the turbocharger, which is vital for maintaining the turbocharger’s efficiency and the overall performance of the engine 1.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger oil drain connections are integral to the functioning of the turbocharger system. They allow for the controlled drainage of oil that has lubricated the turbocharger’s moving parts. This process is crucial for preventing oil buildup, which can lead to inefficiencies and potential damage. By ensuring that oil is regularly drained, these connections help maintain the turbocharger’s operational integrity and contribute to the engine’s performance 2.

Role and Function in Truck Operation

In the context of commercial trucks, the Turbocharger Oil Drain Connection plays a specific role in the turbocharger’s operation. It ensures that oil used for lubrication is efficiently drained, which helps in maintaining the turbocharger’s efficiency. This, in turn, supports the engine’s performance by ensuring that the turbocharger operates within optimal parameters. The connection’s role is particularly significant in heavy-duty applications where the turbocharger is subjected to rigorous conditions 3.

Key Features

The Turbocharger Oil Drain Connection is characterized by several key features that enhance its performance and durability. Its design incorporates precise engineering to ensure a secure fit and efficient oil drainage. The materials used in its construction are selected for their durability and resistance to the high temperatures and pressures encountered in turbocharger systems. Additionally, the connection may feature unique attributes such as anti-corrosion coatings or specialized threading to further enhance its reliability and longevity 4.

Benefits of Using the Turbocharger Oil Drain Connection

Utilizing the Turbocharger Oil Drain Connection offers several advantages. It contributes to improved turbocharger longevity by ensuring that oil is efficiently managed within the system. This efficient oil management also enhances engine performance, as a well-maintained turbocharger can operate more effectively. Furthermore, the connection’s design and materials reduce the need for frequent maintenance, offering a cost-effective solution for commercial truck operators 5.

Installation Process

Installing the Turbocharger Oil Drain Connection requires careful attention to detail to ensure proper fitting and functionality. The process involves securing the connection to the turbocharger housing, ensuring that it is aligned correctly to facilitate efficient oil drainage. It is important to follow manufacturer guidelines to avoid common installation pitfalls that could compromise the connection’s effectiveness. Best practices include verifying the connection’s tightness and ensuring that all components are free from debris before installation 6.

Troubleshooting Common Issues

Common problems associated with turbocharger oil drain connections can include leaks, blockages, or inefficient drainage. These issues can often be diagnosed through visual inspection and testing the turbocharger’s oil drainage system. Troubleshooting steps may involve cleaning or replacing the connection if it is found to be faulty. Regular maintenance and inspections can help identify potential issues before they lead to more significant problems 7.

Maintenance Tips

To ensure the longevity and efficiency of the Turbocharger Oil Drain Connection, regular maintenance practices are recommended. This includes routine checks for signs of wear or damage, ensuring that the connection remains securely fitted, and verifying that oil drainage is occurring as expected. Replacement of the connection should be considered as part of the turbocharger’s maintenance schedule to prevent unexpected failures 8.

Cummins: A Brief Overview

Cummins Inc. is a renowned manufacturer in the commercial truck industry, known for its commitment to quality and innovation. With a diverse product range that includes engines, filtration systems, and turbochargers, Cummins has established a reputation for producing reliable and high-performance automotive components. The company’s dedication to excellence is evident in its manufacturing processes and the durability of its products, making it a preferred choice for commercial truck operators worldwide.

Turbocharger Oil Drain Connection (Part 3943820) Compatibility with Cummins Engines

The Turbocharger Oil Drain Connection, part number 3943820, manufactured by Cummins, is designed to fit a variety of Cummins engine models. This part is crucial for maintaining the integrity of the turbocharger system by facilitating the drainage of oil. Below is a detailed breakdown of the engines that are compatible with this turbocharger oil drain connection.

ISC Series Engines

- ISC CM554

- ISC CM850

These engines are part of the ISC series, known for their reliability and efficiency in various applications.

ISL Series Engines

- ISL CM554

- ISL9 CM2150 SN

- ISL9.5 CM2880 L138

The ISL series engines are designed for heavy-duty applications, providing robust performance and durability.

L Series Engines

- L8.9

- L9 CM2670 L128B

The L series engines are recognized for their versatility and are often used in a range of industrial and commercial applications.

QSC Series Engines

- QSC8.3 CM554

- QSC8.3 CM850 (CM2850)

These engines are part of the QSC series, which is engineered for high-performance and efficiency.

QSL Series Engines

- QSL8.9 CM2150 L141

- QSL9 CM554

- QSL9 CM850 (CM2850)

The QSL series engines are designed to deliver exceptional power and reliability, making them suitable for demanding applications.

This turbocharger oil drain connection is engineered to ensure compatibility with the listed engines, facilitating proper oil drainage and maintaining the health of the turbocharger system.

Role of Part 3943820 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection (Part 3943820) is an essential component in the maintenance and operation of turbocharged engine systems. Its primary function is to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters.

Integration with Turbocharger Plumbing

In turbocharged engines, the turbocharger plumbing system is designed to manage the flow of oil to and from the turbocharger. The Turbocharger Oil Drain Connection is a key part of this system. It is strategically positioned to allow for the periodic removal of oil that has been used to lubricate the turbocharger’s moving parts. This drainage is vital for preventing the buildup of contaminants and ensuring that the oil remains effective in reducing friction and wear.

Interaction with the Turbocharger

The turbocharger itself relies on a consistent supply of clean oil to maintain its performance and longevity. The Turbocharger Oil Drain Connection plays a role in this by ensuring that old or contaminated oil is regularly expelled from the system. This helps in maintaining the turbocharger’s efficiency and preventing issues such as oil coking, which can lead to decreased performance and potential failure.

Contribution to Overall Engine Health

By ensuring that the oil within the turbocharger system is kept clean and free from contaminants, the Turbocharger Oil Drain Connection indirectly contributes to the overall health of the engine. Clean oil leads to better lubrication, which in turn results in reduced wear on engine components, improved fuel efficiency, and enhanced engine performance.

Maintenance and Operational Efficiency

Regular use of the Turbocharger Oil Drain Connection as part of routine maintenance helps in identifying potential issues early. For instance, the presence of metal particles or unusual colors in the drained oil can indicate wear or damage within the turbocharger, allowing for timely intervention and repairs.

Conclusion

In summary, the Turbocharger Oil Drain Connection (Part 3943820) is a vital component in the turbocharger plumbing system, playing a significant role in maintaining the efficiency and reliability of turbocharged engine systems. Its proper installation, regular maintenance, and timely replacement are crucial for ensuring the optimal performance of the turbocharger and the engine as a whole.

-

Fijalkowski, B.T. (2011). Automotive Mechatronics Operational and Practical Issues Volume 1. Springer.

↩ -

Awari, G.K., Kumbhar, V.S., & Tirpude, R.B. (2011). Automotive Systems Principles and Practice. CRC Press.

↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5612990.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5612990.

↩ -

Dempsey, P. (2008). Troubleshooting and Repairing Diesel Engines. McGraw-Hill.

↩ -

Cummins Inc. (n.d.). Fault Code Troubleshooting Manual. Bulletin Number 5612990.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.