This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

The Cummins 3943880 Turbocharger Oil Drain Fitting is a component designed to facilitate the drainage of oil from the turbocharger system in heavy-duty trucks. Its role is significant in maintaining the efficiency and longevity of the turbocharger, ensuring that the engine operates smoothly and effectively 1.

Basic Concepts of Turbocharger Oil Drain Fittings

Turbocharger systems utilize exhaust gases to spin a turbine, which in turn drives a compressor to increase the amount of air entering the engine. Oil is circulated within the turbocharger to lubricate moving parts and help cool the turbine. Over time, contaminants can accumulate in the oil, necessitating its periodic drainage to maintain optimal turbocharger performance. Turbocharger oil drain fittings are designed to allow for the safe and efficient removal of this oil, ensuring that the system remains clean and operates effectively 2.

Purpose of the 3943880 Turbocharger Oil Drain Fitting

The 3943880 Turbocharger Oil Drain Fitting plays a role in the turbocharger system by providing a means to drain oil from the turbocharger. This process helps in removing contaminants and ensuring that the oil remains clean, which is vital for the lubrication and cooling of turbocharger components. By facilitating regular oil changes, the fitting contributes to maintaining optimal turbocharger performance and extending its operational life 1.

Key Features

The 3943880 fitting is constructed from durable materials to withstand the high temperatures and pressures within the turbocharger system. It features a secure connection type that ensures a tight seal, preventing leaks and ensuring efficient oil drainage. The design includes specific attributes that enhance its functionality, such as a streamlined shape that minimizes turbulence during oil flow and a robust construction that resists wear and corrosion 2.

Benefits

Using the 3943880 Turbocharger Oil Drain Fitting offers several advantages. It contributes to improved turbocharger efficiency by ensuring clean oil circulation, which reduces the risk of component wear and failure. Additionally, it helps in reducing maintenance intervals by making the oil drainage process straightforward and efficient. Enhanced overall engine performance is another benefit, as a well-maintained turbocharger system leads to better engine responsiveness and fuel efficiency 1.

Installation Process

Installing the 3943880 fitting involves several steps to ensure a secure and effective fit. Begin by ensuring the turbocharger system is cool and the engine is off. Use the appropriate tools to disconnect the old fitting, if present. Clean the fitting area to remove any debris or old sealant. Apply a compatible sealant to the threads of the new fitting. Carefully screw the 3943880 fitting into place, ensuring it is tightened to the manufacturer’s specified torque. Finally, inspect the connection for any signs of leaks before restarting the engine 2.

Troubleshooting Common Issues

Common problems with turbocharger oil drain fittings include leaks and blockages. To address leaks, first, ensure the fitting is properly tightened. If leaks persist, inspect the fitting and surrounding areas for damage or wear. Blockages can often be resolved by cleaning the fitting and ensuring that the drainage path is clear. Regular inspections and maintenance can help prevent these issues 1.

Maintenance Tips

To ensure the longevity and reliable operation of the 3943880 fitting, regular maintenance practices are recommended. Inspect the fitting during routine turbocharger maintenance checks for signs of wear, corrosion, or leaks. Clean the fitting and surrounding areas to prevent the buildup of contaminants. Follow the manufacturer’s guidelines for oil change intervals to keep the turbocharger system clean and efficient 2.

Compatibility with Cummins Engines

- ISC CM554 and ISL CM554 Engines

The ISC CM554 and ISL CM554 engines are part of Cummins’ lineup of high-performance, heavy-duty engines. These engines are known for their robust design and reliability in demanding applications. The Turbocharger Oil Drain Fitting part number 3943880 is specifically designed to fit these engines, ensuring that the oil drainage process is seamless and effective. This fitting is crucial for preventing oil buildup in the turbocharger, which can lead to overheating and reduced performance.

- QSC8.3 CM554 Engine

The QSC8.3 CM554 engine is another variant in Cummins’ CM554 series, tailored for applications requiring a balance of power and efficiency. The Turbocharger Oil Drain Fitting part number 3943880 is engineered to integrate perfectly with the QSC8.3 CM554 engine, facilitating the efficient removal of oil from the turbocharger. This ensures that the engine operates at optimal levels, maintaining its performance and reliability over time.

Importance of the Turbocharger Oil Drain Fitting

The Turbocharger Oil Drain Fitting part number 3943880 is a vital component in the maintenance of Cummins engines. By ensuring that oil is properly drained from the turbocharger, this fitting helps prevent oil accumulation, which can cause overheating and damage to the turbocharger. This, in turn, helps maintain the overall health and performance of the engine, ensuring that it operates efficiently and reliably.

The fitting’s design and material are specifically chosen to withstand the high temperatures and pressures encountered in engine operation, ensuring durability and long-term performance. Its compatibility with the ISC CM554, ISL CM554, and QSC8.3 CM554 engines makes it a versatile and essential part for maintaining these engines.

Role of Part 3943880 Turbocharger Oil Drain Fitting in Engine Systems

In the orchestration of engine systems, the Turbocharger Oil Drain Fitting (Part 3943880) assumes a significant role, particularly within the turbocharger and its associated plumbing. This fitting is integral to the maintenance and operational integrity of the turbocharger system.

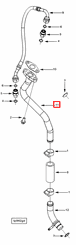

Integration with Turbocharger Plumbing

The Turbocharger Oil Drain Fitting is strategically positioned within the turbocharger plumbing system. Its primary function is to facilitate the drainage of oil from the turbocharger. This is essential for maintaining the cleanliness and efficiency of the oil circulating within the turbocharger. By ensuring that old or contaminated oil is regularly removed, the fitting helps in preserving the turbocharger’s performance and longevity.

Interaction with the Turbocharger

Within the turbocharger itself, the fitting is connected to the oil supply and return lines. It acts as a vital junction point where the oil, after lubricating the turbocharger’s moving parts, is drained away. This process is key to preventing oil buildup, which could lead to increased temperatures and potential damage to the turbocharger.

Contribution to Overall Engine Efficiency

By ensuring that the turbocharger operates with clean, uncontaminated oil, the Turbocharger Oil Drain Fitting indirectly contributes to the overall efficiency of the engine. A well-maintained turbocharger can respond more effectively to changes in engine load, providing better acceleration and power output. Additionally, it aids in reducing the risk of turbocharger failure, which can be both costly and time-consuming to repair.

Maintenance and Operational Benefits

Regular use of the Turbocharger Oil Drain Fitting as part of routine maintenance can significantly extend the service life of the turbocharger. It allows for the easy removal of oil samples, which can be analyzed for contaminants or signs of wear, providing valuable insights into the health of the turbocharger and the engine as a whole.

Conclusion

The Turbocharger Oil Drain Fitting (Part 3943880) is a key component in the turbocharger and its plumbing system. It ensures the turbocharger operates with clean oil, contributing to the efficiency, performance, and longevity of the engine system. Regular maintenance and proper installation of this fitting are essential for optimal engine performance and reliability.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.