This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

The Turbocharger Oil Drain Connection, identified by Part #3944055, is a component manufactured by Cummins, a leader in the commercial truck industry. This part is integral to the operation of heavy-duty truck engines, facilitating the efficient management of oil within the turbocharger system. Understanding its role and functionality is key to maintaining engine performance and longevity.

Basic Concepts of Turbocharger Oil Drain Connection

Turbochargers operate by compressing the air entering the engine, which allows for more fuel to be burned and thus increases power output. To function effectively, turbochargers require lubrication, typically provided by engine oil. The oil drain connection is a component in this system, allowing for the removal of used oil from the turbocharger. This process is vital for maintaining the turbocharger’s efficiency and preventing the buildup of contaminants that could impair performance 1.

Purpose and Function

The Turbocharger Oil Drain Connection plays a role in the turbocharger system by enabling the removal of oil that has circulated through the turbocharger. This function is important for several reasons: it helps in maintaining the cleanliness of the turbocharger, ensures that the lubricant does not become overly contaminated, and contributes to the overall efficiency and reliability of the engine. By facilitating the drainage of oil, this component helps in sustaining optimal turbocharger operation and engine performance 2.

Key Features

The Turbocharger Oil Drain Connection is designed with specific characteristics that enhance its functionality. It is constructed from durable materials to withstand the high temperatures and pressures within the turbocharger environment. The design of the connection ensures a secure fit, preventing leaks and ensuring that oil is effectively drained from the system. Additionally, its compatibility with various Cummins engine models makes it a versatile component for a wide range of applications.

Benefits

Incorporating the Turbocharger Oil Drain Connection into a truck’s engine system offers several advantages. It contributes to improved engine efficiency by ensuring that the turbocharger operates with clean, uncontaminated oil. This, in turn, can lead to reduced maintenance requirements, as the turbocharger is less likely to suffer from performance issues related to oil contamination. Furthermore, the reliability of the turbocharger is enhanced, which can result in more consistent engine performance over time.

Installation and Compatibility

Proper installation of the Turbocharger Oil Drain Connection is important for its effective operation. It is designed to be compatible with a variety of Cummins engine models, ensuring that it can be integrated into different systems without issue. When installing this component, it is important to follow manufacturer guidelines to ensure a secure and leak-free connection. This includes verifying that all connections are tight and that the component is properly aligned with the turbocharger system.

Maintenance and Troubleshooting

Routine maintenance of the Turbocharger Oil Drain Connection is important for ensuring its continued effective operation. This includes regular inspections for signs of wear or damage, as well as ensuring that the connection remains secure and leak-free. In the event of issues such as oil leaks or reduced turbocharger performance, troubleshooting may involve checking the connection for proper installation, inspecting for damage, and ensuring that the oil drainage system is functioning as intended.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions. With a history spanning over a century, Cummins has established a reputation for innovation, quality, and reliability in the commercial truck industry. The company’s commitment to advancing technology and improving efficiency is evident in its diverse product range, which includes engines, filtration systems, and aftermarket parts. Cummins’ dedication to quality and customer satisfaction underscores its position as a trusted provider of automotive components.

Turbocharger Oil Drain Connection (Part 3944055) in Cummins Engines

The Turbocharger Oil Drain Connection, identified by part number 3944055, is a component in the lubrication system of certain Cummins engines. This part is designed to facilitate the drainage of oil from the turbocharger, ensuring that the turbocharger operates efficiently and remains lubricated without excess oil buildup.

Application in Cummins Engines

ISB CM550

The ISB CM550 engine, known for its robust performance and reliability, incorporates the Turbocharger Oil Drain Connection as part of its maintenance and operational integrity. This component ensures that the turbocharger is adequately lubricated, preventing wear and extending the engine’s lifespan.

QSB5.9 44 CM550

Similarly, the QSB5.9 44 CM550 engine benefits from the Turbocharger Oil Drain Connection. This part is integral to the engine’s design, providing a controlled method for oil to return from the turbocharger to the engine’s oil system. This helps maintain optimal operating conditions for the turbocharger, contributing to the engine’s overall efficiency and durability.

Grouping of Engines

Both the ISB CM550 and QSB5.9 44 CM550 engines fall under the category of high-performance, heavy-duty engines. They are designed for demanding applications, where reliability and efficiency are paramount. The Turbocharger Oil Drain Connection is a shared component in these engines, highlighting its importance in maintaining the integrity of the turbocharger system across different engine models.

Role of Part 3944055 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection is an essential component in the maintenance and operation of turbocharger systems within various engine setups. This part facilitates the drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters.

Integration with Turbocharger Systems

In turbocharger systems, the oil drain connection plays a significant role in maintaining the health and performance of the turbocharger. The turbocharger relies on a continuous supply of oil for lubrication, cooling, and sealing purposes. Over time, contaminants and debris can accumulate in the oil, which, if not properly managed, can lead to decreased efficiency and potential damage to the turbocharger.

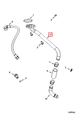

The Turbocharger Oil Drain Connection is designed to interface directly with the turbocharger’s oil system, allowing for the periodic drainage of used oil. This process is vital for preventing the buildup of contaminants and ensuring that fresh, clean oil is circulated through the system. The connection point is typically located at the lower part of the turbocharger housing, where the oil collects.

Interaction with Plumbing Systems

The effectiveness of the Turbocharger Oil Drain Connection is further enhanced by its integration with the engine’s plumbing system. The drainage process involves connecting the turbocharger’s oil drain to the engine’s oil return line or a dedicated drainage system. This setup ensures that the drained oil is efficiently routed away from the turbocharger and back into the engine’s oil sump or a separate collection tank for disposal or recycling.

The plumbing system must be designed to handle the flow of oil from the turbocharger without creating backpressure that could impede the drainage process. Proper sizing and routing of the plumbing lines are essential to maintain the integrity of the oil drainage system. Additionally, the use of appropriate fittings and seals at the connection points ensures that the system remains leak-free and operates under the intended pressure conditions.

Maintenance and Operational Benefits

Regular maintenance of the turbocharger oil system, facilitated by the Turbocharger Oil Drain Connection, contributes to the longevity and reliability of the turbocharger. By ensuring that clean oil is consistently supplied to the turbocharger, the risk of wear, overheating, and failure is significantly reduced. This, in turn, enhances the overall performance and efficiency of the engine.

Moreover, the Turbocharger Oil Drain Connection simplifies the maintenance process by providing a straightforward method for oil drainage. This accessibility allows mechanics and engineers to perform routine checks and maintenance with minimal disruption to the engine’s operation, thereby reducing downtime and maintenance costs.

Conclusion

In summary, the Turbocharger Oil Drain Connection is a vital component in the turbocharger and plumbing systems of an engine. Its role in facilitating efficient oil drainage contributes to the maintenance of optimal turbocharger performance, ensuring the engine operates smoothly and reliably.

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.