This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

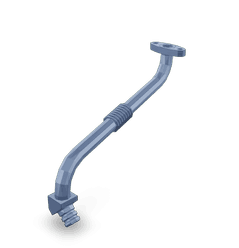

The Turbocharger Oil Drain Connection (Part #3954596) by Cummins is a component designed to facilitate the drainage of oil from the turbocharger in heavy-duty trucks. Its purpose is to ensure that the turbocharger operates efficiently by maintaining proper lubrication and preventing oil buildup, which can lead to performance issues. This part is significant in the operation of heavy-duty trucks as it contributes to the overall reliability and efficiency of the engine.

Basic Concepts of Turbocharger Oil Drain Connection

Turbocharger oil drain connections operate on the principle of allowing excess oil, which lubricates the turbocharger’s moving parts, to be drained away. This process is vital for maintaining the turbocharger’s performance and longevity. The connection is typically located at the lowest point of the turbocharger housing, ensuring that oil can flow out under the influence of gravity. This design helps in keeping the turbocharger clean and operational, thereby supporting the engine’s power output and efficiency 1.

Role and Function in Truck Operation

The Turbocharger Oil Drain Connection plays a role in the overall operation of a truck’s engine by ensuring that the turbocharger remains free of excess oil. This is achieved through a simple yet effective mechanism that allows oil to be periodically drained from the turbocharger. By doing so, it helps in maintaining the optimal performance of the turbocharger, which in turn supports the engine’s ability to deliver power efficiently. Its interaction with other components is minimal, primarily involving the turbocharger housing and the oil drainage system 2.

Key Features

The Turbocharger Oil Drain Connection is characterized by several key features that enhance its functionality and durability. It is typically made from high-quality materials that resist corrosion and wear, ensuring long-term reliability. The design includes a secure fitting mechanism that prevents leaks and ensures a tight seal. Additionally, it may feature a filter or screen to catch debris, further protecting the turbocharger from damage 3.

Benefits

The benefits provided by the Turbocharger Oil Drain Connection include improved engine performance, increased longevity of the turbocharger, and enhanced reliability of the truck’s engine. By ensuring that the turbocharger is free from excess oil and debris, this part contributes to smoother operation and reduced maintenance needs. Furthermore, it helps in maintaining the efficiency of the turbocharger, which is crucial for the engine’s overall performance 4.

Installation Process

Installing the Turbocharger Oil Drain Connection involves several steps to ensure proper fitting and functionality. First, the turbocharger housing must be cleaned to remove any old oil or debris. Next, the drain connection is attached to the designated location on the turbocharger, ensuring a secure fit. Tools required may include a wrench for tightening and a cleaning brush for preparing the area. It is important to follow the manufacturer’s instructions closely to avoid damage to the turbocharger or the drain connection.

Maintenance Tips

To ensure optimal performance and longevity of the Turbocharger Oil Drain Connection, regular maintenance is recommended. This includes periodic inspection for signs of wear or damage, such as cracks or leaks. Cleaning the connection and its surrounding area can prevent buildup that might obstruct oil flow. Additionally, checking the tightness of the connection can help in preventing oil leaks, which could lead to turbocharger failure.

Troubleshooting Common Issues

Common issues associated with the Turbocharger Oil Drain Connection may include leaks, blockages, or malfunctions. Leaks can often be traced to a loose connection or damaged fitting, which may require tightening or replacement. Blockages might be caused by debris or thickened oil, necessitating cleaning or flushing of the system. Malfunctions could indicate a more serious issue with the turbocharger itself, requiring professional assessment and repair.

Cummins: A Brief Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes engines, filtration, and power generation products. With a history spanning over a century, Cummins has established a reputation for quality, innovation, and reliability in the automotive industry. The company offers a wide range of products, including diesel and natural gas engines, as well as related technologies and services, catering to various industries and applications.

Turbocharger Oil Drain Connection in Cummins Engines

The Turbocharger Oil Drain Connection, part number 3954596, is a critical component in the maintenance and operation of several Cummins engines. This part is integral to the engine’s lubrication system, ensuring that the turbocharger is properly lubricated and that any excess oil is efficiently drained back into the engine’s oil system.

ISB CM850

In the ISB CM850 engine, the Turbocharger Oil Drain Connection plays a vital role in maintaining the turbocharger’s performance. This engine is known for its robust design and high efficiency, making it a popular choice in various industrial and commercial applications. The part ensures that the turbocharger receives the correct amount of oil for optimal operation, while also preventing oil from accumulating in the turbocharger, which could lead to performance issues or damage.

Grouping of Engines

The Turbocharger Oil Drain Connection is designed to fit seamlessly into the Cummins engine family, including but not limited to the ISB CM850. This part is engineered to meet the specific requirements of Cummins engines, ensuring compatibility and reliability across different models. The design and material of the part are chosen to withstand the high pressures and temperatures typically encountered in engine operation, providing a durable and long-lasting solution for engine maintenance.

Role of Part 3954596 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection is an essential component in the efficient operation of turbochargers within engine systems. This part facilitates the drainage of oil from the turbocharger, ensuring that the lubrication system remains effective and that oil does not accumulate to problematic levels.

Integration with Turbocharger

In the context of a turbocharger, the oil drain connection is responsible for allowing the used lubrication oil to exit the turbocharger housing. This is important because turbochargers operate at high speeds and temperatures, which can lead to oil degradation if not properly managed. The drained oil is then typically returned to the engine’s lubrication system for filtration and recirculation, maintaining optimal lubrication conditions.

Interaction with Plumbing Systems

The oil drain connection interfaces with the engine’s plumbing system, which includes oil lines and filters. Proper installation of the oil drain connection ensures a secure and leak-free pathway for the oil to travel from the turbocharger back to the sump or oil reservoir. This integration is vital for maintaining system pressure and ensuring that the oil reaches its destination without contamination or loss.

Overall System Functionality

By effectively managing the oil drainage, the Turbocharger Oil Drain Connection contributes to the overall reliability and performance of the engine system. It helps in preventing oil buildup within the turbocharger, which could otherwise lead to decreased efficiency and potential damage. Additionally, it supports the maintenance of clean oil within the system, which is essential for the longevity of both the turbocharger and the engine components it services.

Conclusion

The Turbocharger Oil Drain Connection (Part #3954596) by Cummins is a vital component in the maintenance and efficient operation of heavy-duty truck engines. By ensuring proper drainage of oil from the turbocharger, it contributes to the overall reliability, efficiency, and longevity of the engine. Regular maintenance and proper installation are key to maximizing the benefits of this part, ensuring that the turbocharger and engine operate at optimal levels.

-

Boyce, M. P. (2011). Gas Turbine Engineering Handbook (4th ed.). Butterworth-Heinemann.

↩ -

Isermann, R. (2017). Combustion Engine Diagnosis. Springer Vieweg.

↩ -

Taghavifar, H., & Mardani, A. (2017). Offroad Vehicle Dynamics Analysis Modelling and Optimization. Springer.

↩ -

Bonnick, A. (2004). A Practical Approach to Motor Vehicle Engineering and Maintenance. Elsevier.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.