This truck part is made by Cummins®. We guarantee that all of our parts are from the OEM (original equipment manufacturer), ensuring a proper fit and quality manufacturing.

We honor the warranty provided by the original equipment manufacturer.

Introduction

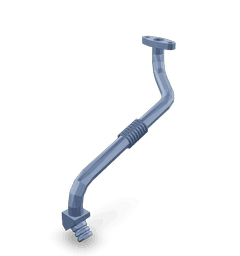

The Turbocharger Oil Drain Connection, identified by part number 3967878, is a component manufactured by Cummins, a leader in the heavy-duty truck engine industry. This part is integral to the turbocharger system, ensuring efficient oil drainage and maintaining optimal lubrication within the turbocharger. Understanding its role and functionality is key to maintaining the performance and longevity of heavy-duty diesel engines.

Basic Concepts

Turbochargers are devices that increase an engine’s power output by forcing extra air into the combustion chamber. In diesel engines, turbochargers enhance efficiency and power by compressing the intake air, allowing for more fuel to be burned. Oil lubrication is vital for turbocharger operation, as it reduces friction between moving parts, dissipates heat, and prevents wear. Proper lubrication ensures the turbocharger operates smoothly and efficiently 1.

Purpose of the Turbocharger Oil Drain Connection

The Turbocharger Oil Drain Connection serves a specific function within the turbocharger system. It facilitates the drainage of oil from the turbocharger, ensuring that lubrication is maintained at optimal levels. By allowing excess oil to be drained, it helps prevent oil buildup, which can lead to inefficiencies and potential damage. This connection is crucial for sustaining the turbocharger’s performance and longevity by ensuring consistent lubrication 2.

Key Features

The Turbocharger Oil Drain Connection is designed with several features that enhance its performance and durability. Constructed from high-quality materials, it is built to withstand the high pressures and temperatures associated with turbocharger operation. The connection type is engineered to provide a secure fit, minimizing the risk of leaks. Additionally, its design includes features that facilitate easy installation and maintenance, ensuring it can be efficiently integrated into the turbocharger system.

Benefits

Incorporating the Turbocharger Oil Drain Connection into a turbocharger system offers several advantages. It contributes to improved engine performance by ensuring that the turbocharger operates under optimal lubrication conditions. This, in turn, can extend the turbocharger’s lifespan and enhance the overall reliability of the engine in heavy-duty applications. Consistent oil drainage helps maintain the turbocharger’s efficiency, leading to better fuel economy and reduced maintenance costs over time 3.

Installation Process

Installing the Turbocharger Oil Drain Connection requires careful attention to detail to ensure proper functionality. The process involves several steps: first, ensuring the turbocharger is clean and free of debris; second, aligning the connection with the turbocharger’s oil drain port; and third, securing it in place using the appropriate tools. It is important to follow manufacturer guidelines to avoid misalignment or improper sealing, which could lead to leaks or inefficient oil drainage.

Maintenance and Troubleshooting

Routine maintenance of the Turbocharger Oil Drain Connection is vital to ensure its continued effectiveness. This includes regular inspections for signs of wear or damage, such as cracks or leaks, and ensuring the connection remains securely fastened. Troubleshooting may involve checking for blockages in the oil drain path or verifying that the connection is properly aligned. Addressing these issues promptly can prevent more significant problems and ensure the turbocharger system operates efficiently.

Common Issues and Solutions

Frequent problems associated with the Turbocharger Oil Drain Connection include leaks and blockages. Leaks may occur due to improper installation or wear over time, while blockages can result from debris or oil buildup. Solutions involve inspecting the connection for damage, cleaning the oil drain path, and ensuring the connection is correctly installed. Preventive measures include regular maintenance checks and using high-quality lubricants to reduce the risk of blockages.

Cummins Overview

Cummins Inc. is a global power leader that designs, manufactures, and distributes a wide range of power solutions, including engines, filtration, and emission solutions. With a history spanning over a century, Cummins is renowned for its commitment to quality, innovation, and customer satisfaction. The company’s extensive product range and reputation in the heavy-duty truck industry underscore its dedication to providing reliable and efficient power solutions.

Turbocharger Oil Drain Connection in Cummins Engines

The Turbocharger Oil Drain Connection, part number 3967878, is a critical component in the maintenance and operation of several Cummins engines. This part is integral to the engine’s lubrication system, ensuring that the turbocharger is properly lubricated and that any excess oil is efficiently drained back into the engine’s oil system.

ISB CM850 Engine

In the ISB CM850 engine, the Turbocharger Oil Drain Connection plays a pivotal role in maintaining the turbocharger’s performance. This engine is known for its robust design and high efficiency, making it a popular choice in various industrial and commercial applications. The turbocharger oil drain connection ensures that the oil used to lubricate the turbocharger is effectively managed, preventing oil build-up and ensuring smooth operation.

Grouping of Engines

The Turbocharger Oil Drain Connection is designed to fit seamlessly into various Cummins engine configurations. While the ISB CM850 is a notable example, this part is also compatible with other Cummins engines that utilize similar turbocharger systems. The design of the part ensures that it can integrate with the engine’s oil system, providing a reliable connection for oil drainage and preventing leaks.

By ensuring that the turbocharger is properly lubricated and that any excess oil is efficiently managed, the Turbocharger Oil Drain Connection contributes to the overall reliability and longevity of the engine. This part is a testament to Cummins’ commitment to quality and precision in engine design and maintenance.

Role of Part 3967878 Turbocharger Oil Drain Connection in Engine Systems

The Turbocharger Oil Drain Connection, identified as part 3967878, is an essential component in the turbocharger plumbing system of various engine setups. Its primary function is to facilitate the drainage of oil from the turbocharger, ensuring that the lubrication system remains efficient and that the turbocharger operates within optimal parameters.

Integration with Turbocharger Plumbing

In the turbocharger plumbing system, the Turbocharger Oil Drain Connection is strategically positioned to interface with the oil supply and return lines. This connection point allows for the controlled release of oil that has lubricated the turbocharger’s moving parts, such as the turbine and compressor wheels.

Interaction with Lubrication System

The Turbocharger Oil Drain Connection works in tandem with the engine’s lubrication system. Oil is supplied to the turbocharger through dedicated lines, which branch off from the main oil gallery. After lubricating the turbocharger’s components, the oil must be drained back into the sump to be recirculated. The Turbocharger Oil Drain Connection ensures this process is seamless, preventing oil buildup and maintaining the correct oil level within the turbocharger.

Maintenance and Operational Efficiency

Regular maintenance of the Turbocharger Oil Drain Connection is vital for the turbocharger’s longevity and performance. By ensuring that oil is efficiently drained, the connection helps prevent oil coking, a condition where oil residues harden and can lead to turbocharger failure. Additionally, it aids in maintaining the turbocharger’s thermal efficiency by ensuring that the oil does not overheat within the system.

Role in Diagnostic and Monitoring Systems

In modern engine systems equipped with diagnostic and monitoring capabilities, the Turbocharger Oil Drain Connection may also play a role in providing data on oil flow and condition. Sensors placed near this connection can monitor oil temperature, pressure, and flow rate, offering valuable insights into the turbocharger’s health and performance.

Conclusion

The Turbocharger Oil Drain Connection, part 3967878, is a pivotal component in the turbocharger plumbing system. Its role in facilitating efficient oil drainage, interacting with the lubrication system, aiding in maintenance, and potentially contributing to diagnostic processes underscores its importance in ensuring the turbocharger and, by extension, the engine operate at peak efficiency.

-

Mom, Gijs. The Evolution of Automotive Engineering: A Handbook. SAE International, 2023.

↩ -

Wang, Yushu. Introduction to Engine Valvetrains. SAE International, 2007.

↩ -

Hu, Haoran, Simon J Baseley, and Xubin Song. Advanced Hybrid Powertrains for Commercial Vehicles Second Edition. SAE International, 2021.

↩

SPECIFICATIONS

RECOMMENDED PARTS

* Variable geometry turbocharger and electronic actuator repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after October 1, 2018.

* Diesel Oxidation Catalyst (DOC), Diesel Particulate Filter (DPF), Selective Catalyst Reduction (SCR) catalyst, and Electronic Control Module (ECM) repairs are not eligible to be claimed as over-the-counter under New or ReCon parts warranty for parts installed after January 1, 2020.

* These restrictions are only applicable to New parts and ReCon parts coverages for the components listed above sold to a customer in the US or Canada. All other coverages are excluded. All other regions are excluded.